Method for manufacturing PCB short slot

A technology of PCB boards and manufacturing methods, applied in the field of PCB manufacturing, can solve the problems of uneven stress on both sides of the drill bit, low yield rate of PCB boards, and increased production costs, so as to reduce unnecessary scrapping, reduce production costs, and reduce production costs. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

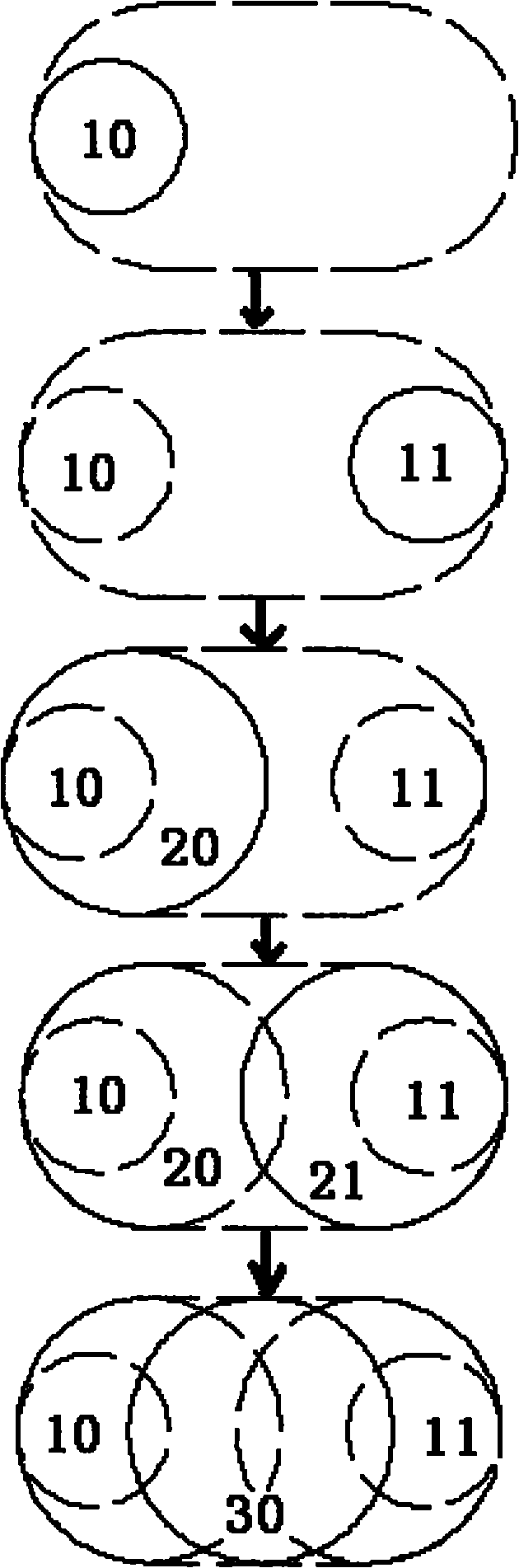

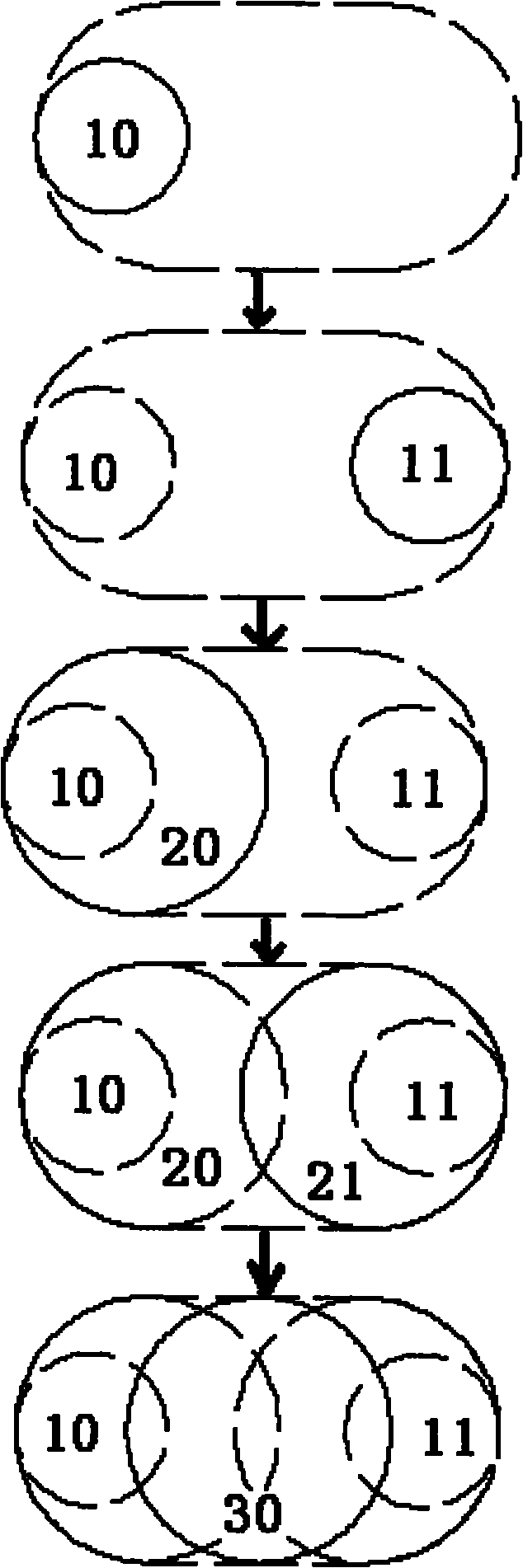

[0014] as attached figure 1 As shown, the manufacturing method of the short slot hole of the present invention is to increase the guide holes 10 and 11 when the drilling pattern is made, so that when the drills are stacked, the drill tips have a part in a suspended state, which effectively prevents the drill tips from being stressed. Uniform condition.

[0015] During the specific operation, at first, according to the made slot pattern, the drilling process (steps 1 and 2) of the two pilot holes 10 and 11 is symmetrically carried out on both edges of the long diameter of the slot hole (steps 1 and 2). The edges of the guide holes and slots are inscribed. The diameters of the guide holes 10 and 11 need to be less than half of the long diameter of the slot, that is, the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com