Preparation method of two-dimensional nano muscovite

A two-dimensional nano, muscovite technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem that the interlayer force of muscovite is difficult to overcome, the cost is high, and mica is difficult to be stripped to several Nano and other issues, to achieve the effect of good peeling effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

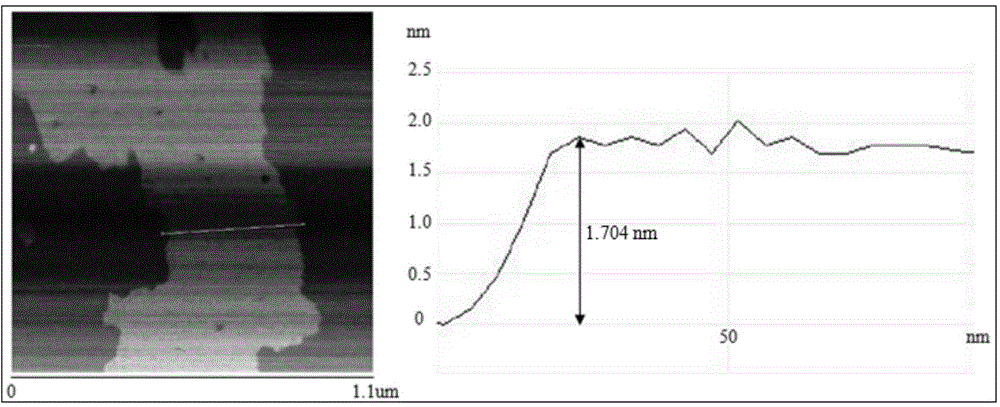

[0024] Heat up 1g of the purified muscovite powder to 650°C at a rate of 5°C / min in a roasting furnace, calcinate for 5h, and cool naturally; place the calcined muscovite powder in 50ml of saturated LiNO 3 solution, react at 70°C for 25 days, add 10g LiNO to the solution every 3 days 3 After completion, centrifuge and wash with water for 3 times; place the obtained muscovite powder in 50ml saturated octadecyltrimethylammonium chloride solution, react at 95°C for 3 days, and centrifuge with 50% ethanol solution with volume percentage concentration after completion After washing for 5 times, the muscovite powder was placed in 100ml of 50% ethanol solution for 20min sonication to obtain two-dimensional nano muscovite. Such as figure 1 Shown is the atomic force microscope photo of the prepared two-dimensional muscovite. It can be seen from the figure that the prepared two-dimensional muscovite has a surface size larger than 1um and a thickness of about 1.704nm.

Embodiment 2

[0026] 1g of purified muscovite powder was heated to 750°C at a rate of 50°C / min in a roasting furnace, calcined for 2 hours, and cooled naturally; the calcined muscovite powder was mixed with NaNO 3 Mix evenly at a ratio of 1:50, place in a muffle furnace, react at 350°C for 10 days, and centrifuge and wash with water for 3 times after completion; place the obtained muscovite powder in 50ml of saturated cetyl dimethyl benzyl chloride react in ammonium chloride solution at 80°C for 3 days, centrifuge and wash 5 times with 50% ethanol solution by volume percentage after completion, freeze-dry, and grind for 5 hours with a three-head grinder to obtain two-dimensional nano muscovite.

Embodiment 3

[0028] Heat 1g of the purified muscovite powder to 700°C at a rate of 30°C / min in a roasting furnace, calcine for 3 hours, and cool naturally; mix the calcined muscovite powder with LiCl at a ratio of 1:150, and place in a muffle furnace reaction at 300°C for 2 days, and centrifuged and washed 3 times with water after completion; the obtained muscovite powder was placed in 50ml of saturated benzylmethylethylamine chloride solution, reacted at 80°C for 3 days, and after completion, use a concentration of 50% by volume The ethanol solution was centrifuged and washed 5 times, and the muscovite powder was placed in 150 ml of saturated benzylmethylethylamine solution and sonicated for 20 min to obtain two-dimensional nano muscovite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com