Antibacterial bathroom ceramic article and preparation method thereof

A ceramic product and green body technology, applied in the field of antibacterial sanitary ceramic products and its preparation, can solve the problems of high water absorption and poor antibacterial performance, and achieve the effects of easy operation, reduced porosity, and lower sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

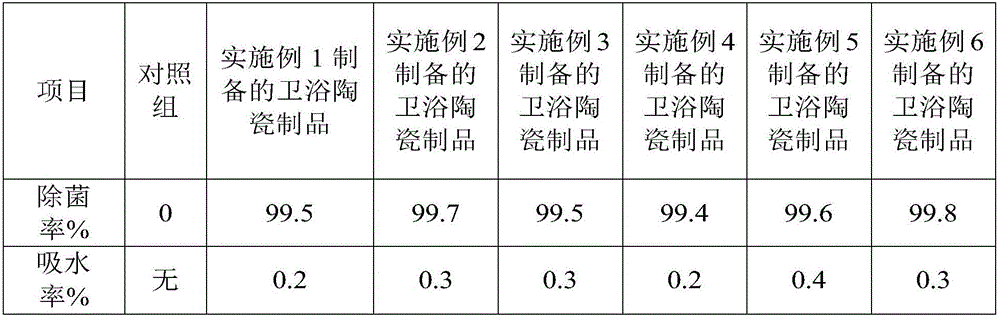

Examples

Embodiment 1

[0031] An antibacterial sanitary ceramic product, including a body and a glaze. The raw materials and their mass percentages for preparing the body are: 30% talc, 30% kaolin, 10% anorthite, 10% bauxite, 10% chlorite, Muscovite 5%, ilmenite 3%, wollastonite 1%, silicon nitride 1%; the raw materials and their mass percentages for preparing the glaze are: talc 40%, anorthite 35%, borax 5%, zinc oxide 6 %, titanium dioxide 10%, zirconium silicate 3%, nano-silver 1%; among them, the particle size of silicon nitride is 90μm; the particle size of zirconium silicate is 40μm; the particle size of titanium dioxide is 50nm; the particle size of zinc oxide is 50nm; the particle size of nano-silver is 20nm.

Embodiment 2

[0033] An antibacterial sanitary ceramic product, comprising a body and a glaze. The raw materials and their mass percentages for preparing the body are: talc 35%, kaolin 25%, anorthite 15%, bauxite 8%, chlorite 5%, Muscovite 6%, ilmenite 2%, wollastonite 2%, silicon nitride 2%; the raw materials and mass percentages for preparing the glaze are: talc 45%, anorthite 25%, borax 3.3%, zinc oxide 10 %, titanium dioxide 8%, zirconium silicate 8%, nano silver 0.7%; among them, the particle size of silicon nitride is 120μm; the particle size of zirconium silicate is 60μm; the particle size of titanium dioxide is 65nm; the particle size of zinc oxide is 65nm; the particle size of nano-silver is 25nm.

Embodiment 3

[0035] An antibacterial sanitary ceramic product, comprising a body and a glaze. The raw materials and their mass percentages for preparing the body are: 40% talc, 20% kaolin, 8% anorthite, 6% bauxite, 8% chlorite, Muscovite 8%, ilmenite 4%, wollastonite 3%, silicon nitride 3%; the raw materials and mass percentages for preparing the glaze are: talc 50%, anorthite 30%, borax 2%, zinc oxide 7.5 %, titanium dioxide 5%, zirconium silicate 5%, nano-silver 0.5%; among them, the particle size of silicon nitride is 150μm; the particle size of zirconium silicate is 80μm; the particle size of titanium dioxide is 80nm; the particle size of zinc oxide is 80nm; the particle size of nano-silver is 30nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com