Composite polyphenylene sulfide resin and preparation method thereof

A polyphenylene sulfide resin and polyphenylene sulfide technology are applied in the field of composite polyphenylene sulfide resin and its preparation, which can solve the problems of low glass transition temperature, low elongation, low impact strength and the like, and achieve low cost , the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

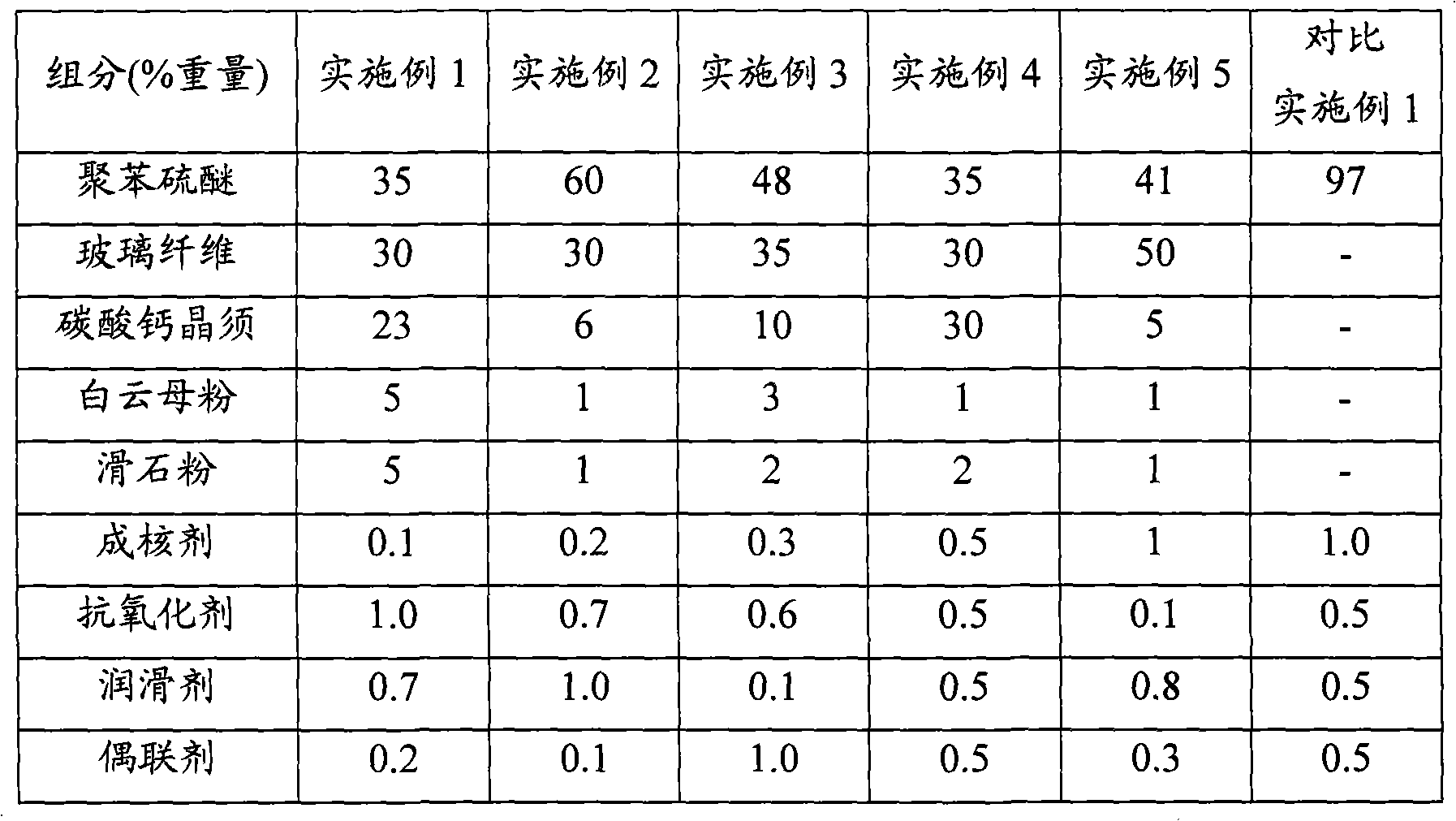

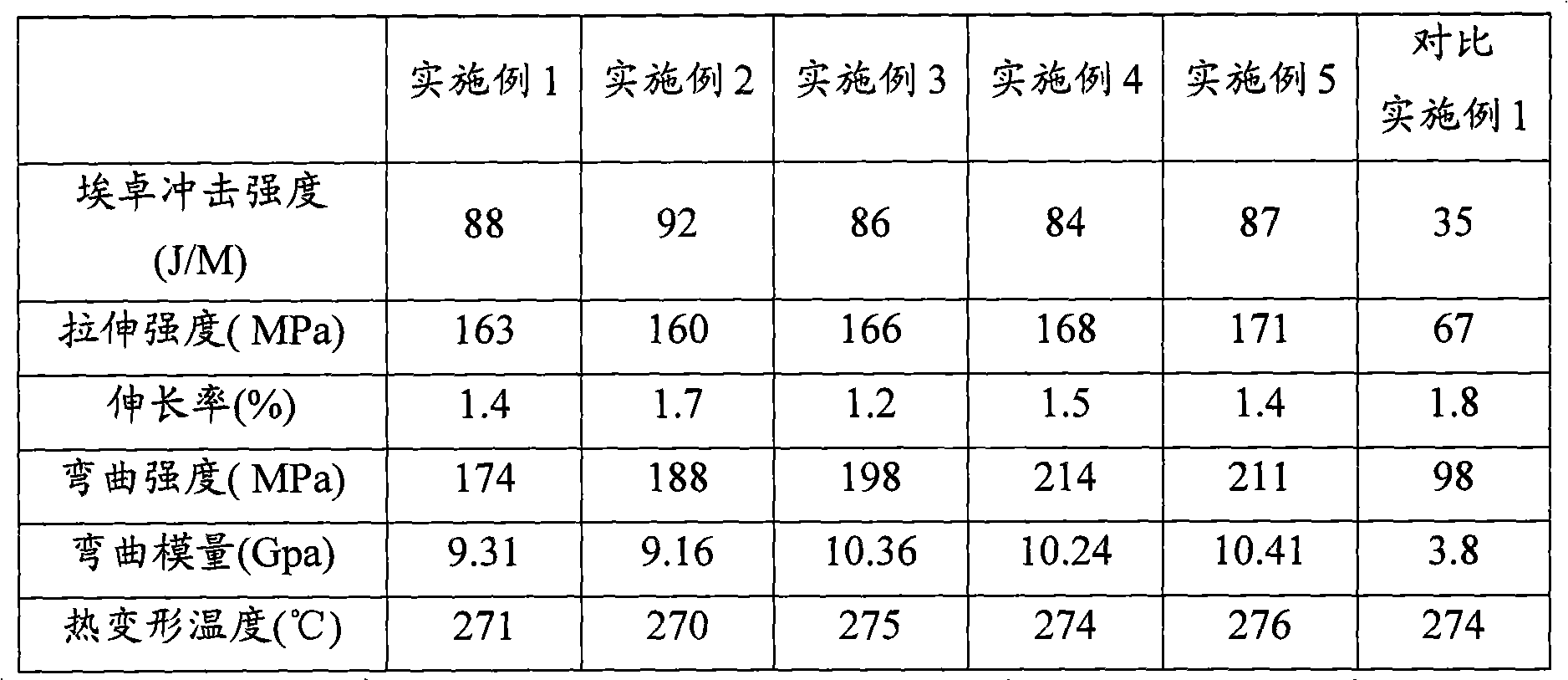

[0019] As shown in Table 1, accurately weigh 350 grams of polyphenylene sulfide, 300 grams of glass fiber, 230 grams of calcium carbonate whiskers, 50 grams of muscovite powder, 50 grams of talcum powder, 1 gram of NC-4 [di(p-ethyl Benzylidene) sorbitol], 6 grams of N, N'-hexamethylene bis (3,5-di-tert-butyl-4-hydrocarbyl phenylpropanamide and 4 grams of pentaerythritol bis-diphosphite bis (2,4 - a mixture of di-tert-butylphenyl) esters, 7 grams of ethylene bis fatty acid amide, and 2 grams of γ-aminopropyltriethoxysilane. Add polyphenylene sulfide to the mixer, followed by γ-aminopropyl Triethoxysilane, pre-mixed for 2-3 minutes, then add all other raw materials except glass fiber, and continue to mix for 3-6 minutes. Twin-screw extruder extrudes the pre-mixed raw materials, and the temperature of one zone is 270 ° C. The temperature of the second zone is 280°C, the temperature of the third zone is 290°C, the temperature of the fourth zone is 290°C, the temperature of the fif...

Embodiment 2

[0021] As shown in Table 1, accurately weigh 600 grams of polyphenylene sulfide, 300 grams of glass fiber, 60 grams of calcium carbonate whiskers, 10 grams of muscovite powder, 10 grams of talcum powder, 2 grams of sodium benzoate, 4.2 grams of 1,3, 5-tris(4-tert-butyl-3-hydrocarbyl-2,6-dimethylphenyl)-1,3,5-triazine-2,4,6-(1H,3H,5H)-trione Mixture with 2.8 grams of dilauryl thiodipropionate, 10 grams of stearic acid, and 1 gram of gamma-glycidoxypropyltrimethoxysilane. Add polyphenylene sulfide to the mixer, followed by gamma-glycidoxypropylene trimethoxysilane, pre-mix for 2-3 minutes, then add all other materials except glass fiber, continue mixing for 3-6 minutes. The twin-screw extruder extrudes pre-mixed raw materials, the temperature of the first zone is 260°C, the temperature of the second zone is 290°C, the temperature of the third zone is 300°C, the temperature of the fourth zone is 290°C, the temperature of the fifth zone is 280°C, and the temperature of the sixth z...

Embodiment 3

[0023] As shown in Table 1, accurately weigh 480 grams of polyphenylene sulfide, 350 grams of glass fiber, 100 grams of calcium carbonate whiskers, 30 grams of muscovite powder, 20 grams of talcum powder, 1.2 grams of NC-4 [di(p-ethyl A mixture of benzylidene)sorbitol and 1.8 grams of sodium benzoate, 6 grams of 4,4'-thiobis(2,6-tert-butylphenol), 1 gram of pentaerythritol stearate, and 4 grams of tris(N- A mixture of isopropyl β-aminoethyl-β-aminoethyl) titanate and 6 g of γ-glycidyloxypropyltrimethoxysilane. Add polyphenylene sulfide to the mixer, then add tris(N-β-aminoethyl-β-aminoethyl)isopropyl titanate and γ-glycidyl etheroxypropylenetrimethoxysilane, pre-mix 2- 3 minutes, then add all other ingredients except fiberglass and continue mixing for 3-6 minutes. The twin-screw extruder extrudes pre-mixed raw materials, the temperature of the first zone is 265°C, the temperature of the second zone is 285°C, the temperature of the third zone is 290°C, the temperature of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com