A fully-glazed frit and a preparing method thereof

A technology of fully glazed and fritted blocks, applied in the field of ceramics, can solve the problems of weak antifouling ability, easy to wear and scratch of fully glazed tiles, and achieve the effect of high wear resistance and tight glass structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

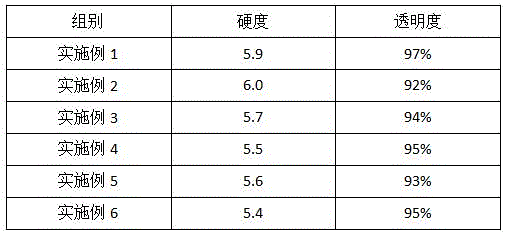

Examples

Embodiment 1

[0020] Weigh 20 parts of quartz, 19 parts of non-calcined alumina, 25 parts of dolomite, 20 parts of wollastonite, 10 parts of potassium feldspar, 1 part of soda ash, and 5 parts of fine powder. Mix evenly, melt at 1540°C, keep warm for 2.5 hours, quench in water, dry and crush to obtain frit.

Embodiment 2

[0022] Weigh 22 parts of quartz, 20 parts of non-calcined alumina, 28 parts of dolomite, 22 parts of wollastonite, 10 parts of potassium feldspar, 1 part of soda ash, and 5 parts of fine powder. Mix evenly, melt at 1540°C, keep warm for 2.5 hours, quench in water, dry and crush to obtain frit. (pinhole)

Embodiment 3

[0024] Weigh 22 parts of quartz, 20 parts of non-calcined alumina, 25 parts of dolomite, 20 parts of wollastonite, 14 parts of potassium feldspar, 1 part of soda ash, and 5 parts of fine powder. Mix evenly, melt at 1500°C, keep warm for 2.5 hours, quench in water, dry and crush to obtain frit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com