Cellulose film and method for producing the same

a technology of cellulose film and cellulose film, which is applied in the field of cellulose film and a method for producing the same, can solve the problems of contaminating the equipment for producing the polarizing plate, affecting the production efficiency of cellulose film, so as to reduce the friction coefficient, reduce the production cost of cellulose film, and improve the uv absorption and pliability of cellulose film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Production and Evaluation of Cellulose Film

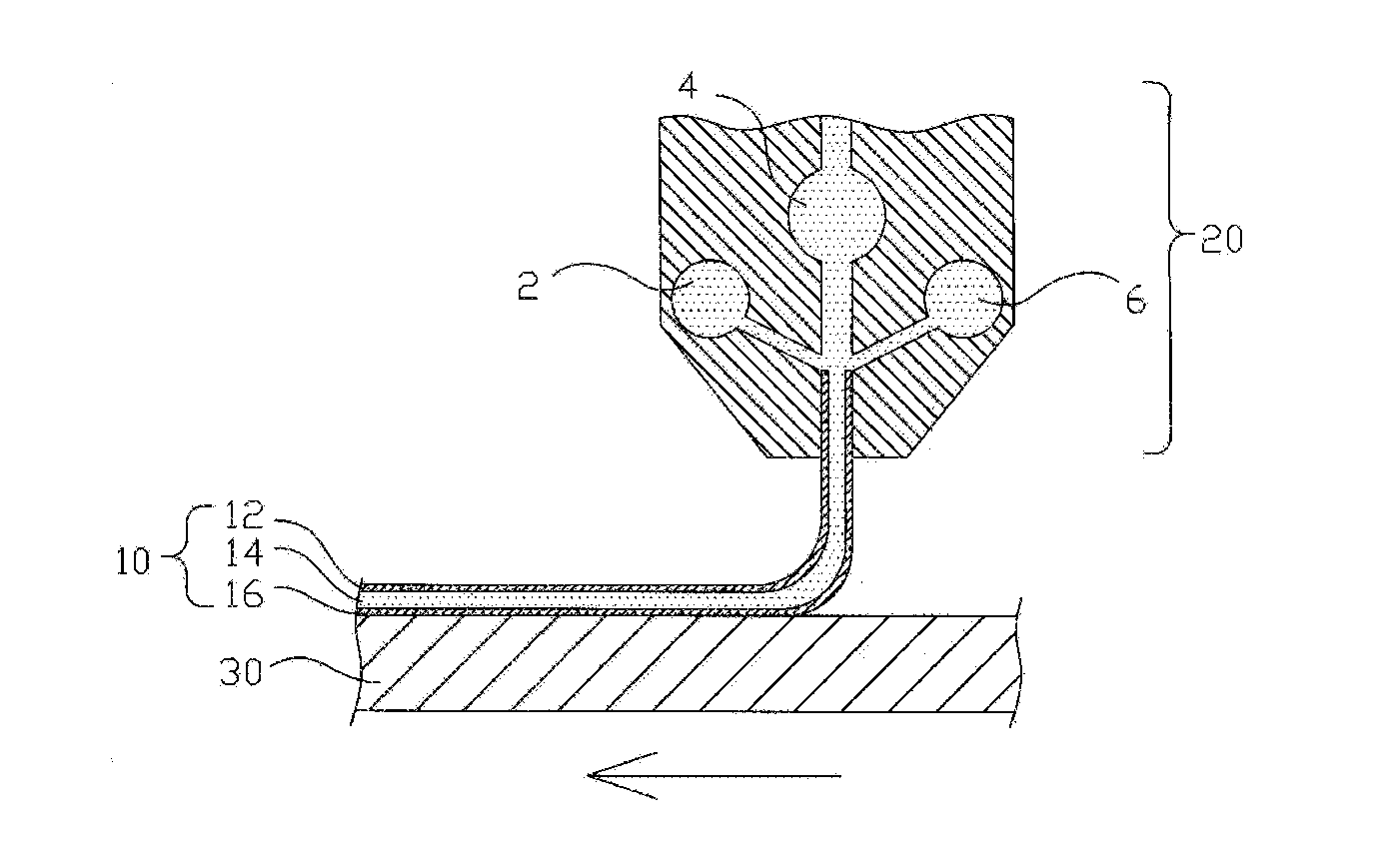

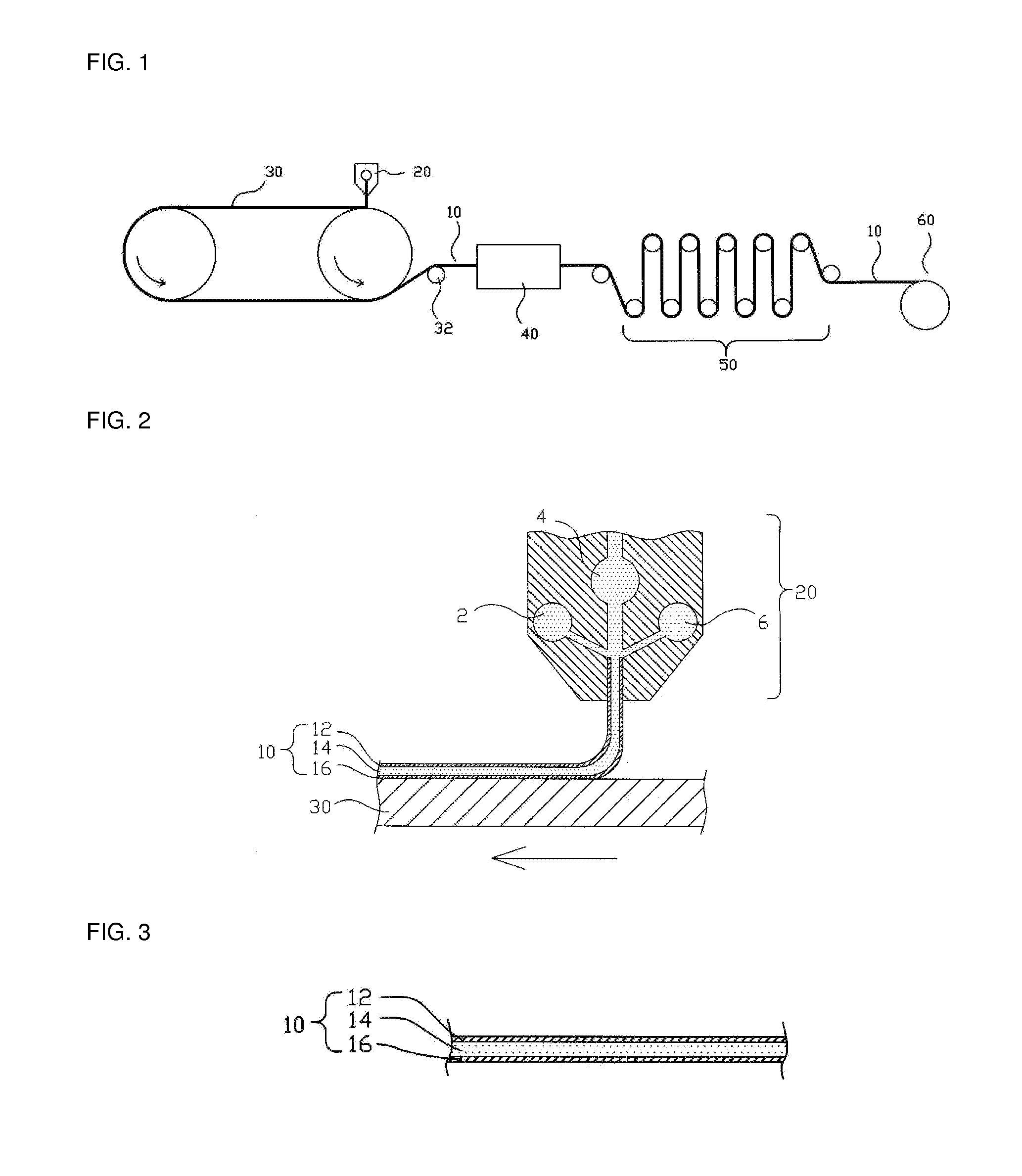

[0030]The first casting solution 2, the second casting solution 4 and the third casting solution 6 were prepared. The first casting solution 2 included 18 weight part of triacetyl cellulose (TAC) as a cellulose resin, 81.76 weight part of methylene chloride (MC) as a solvent for dissolving the cellulose resin and 0.2 weight part of aliphatic polyhydric alcohol ester as a non-phosphoric acid ester type plasticizer. The second casting solution 4 included 15.84 weight part of TAC, 81.76 weight part of MC, 1.4 weight part of the phosphoric acid ester type plasticizer (triphenylphosphate) and 0.2 weight part of aliphatic polyhydric alcohol ester as plasticizers, and 0.25 weight parts of benzotriazole compound as a UV absorbent. The third casting solution 6 included 18 weight part of TAC, 81.76 weight part of MC, 0.2 weight part of aliphatic polyhydric alcohol ester as a non-phosphoric acid ester type plasticizer and 0.002 weight part of silica h...

example 2

Production and Evaluation of Cellulose Film

[0031]The first and third casting solutions 2, 6 for producing the front layer 12 and the rear layer 16 of the cellulose film 10 were prepared by 18 weight part of TAC, 81.76 weight part of MC and 0.2 weight part of aliphatic polyhydric alcohol ester as a plasticizer and 0.002 weight part of fine particles. The second casting solution 4 for producing the inner layer 14 of the film 10 was prepared by using 15.84 weight part of TAC, 81.76 weight part of MC, 1.4 weight % of the phosphoric acid ester plasticizer (triphenylphosphate, tricresylphosphate or cresyl-diphenylphosphate) and 0.2 weight part of aliphatic polyhydric alcohol ester as a plasticizer, and 0.25 weight part of benzotriazole compounds as a UV absorbent. By using the die 20 in FIG. 2, each of the first casting solution 2, the second casting solution 4 and the third casting solution 6 was casted into the surface of a metal belt 30 to form a sheet having the thickness of 90 μm and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| total thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com