Fluosilicic modification water-soluble acrylic resin dispersion and application thereof

A water-soluble acrylic acid, fluoro-silicon modification technology, applied in the direction of coating, etc., can solve the problems of weakening the use value of fluoro-silicon monomer, water resistance, etc., to achieve good appearance and dispersion stability, hardness improvement, water dilution Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

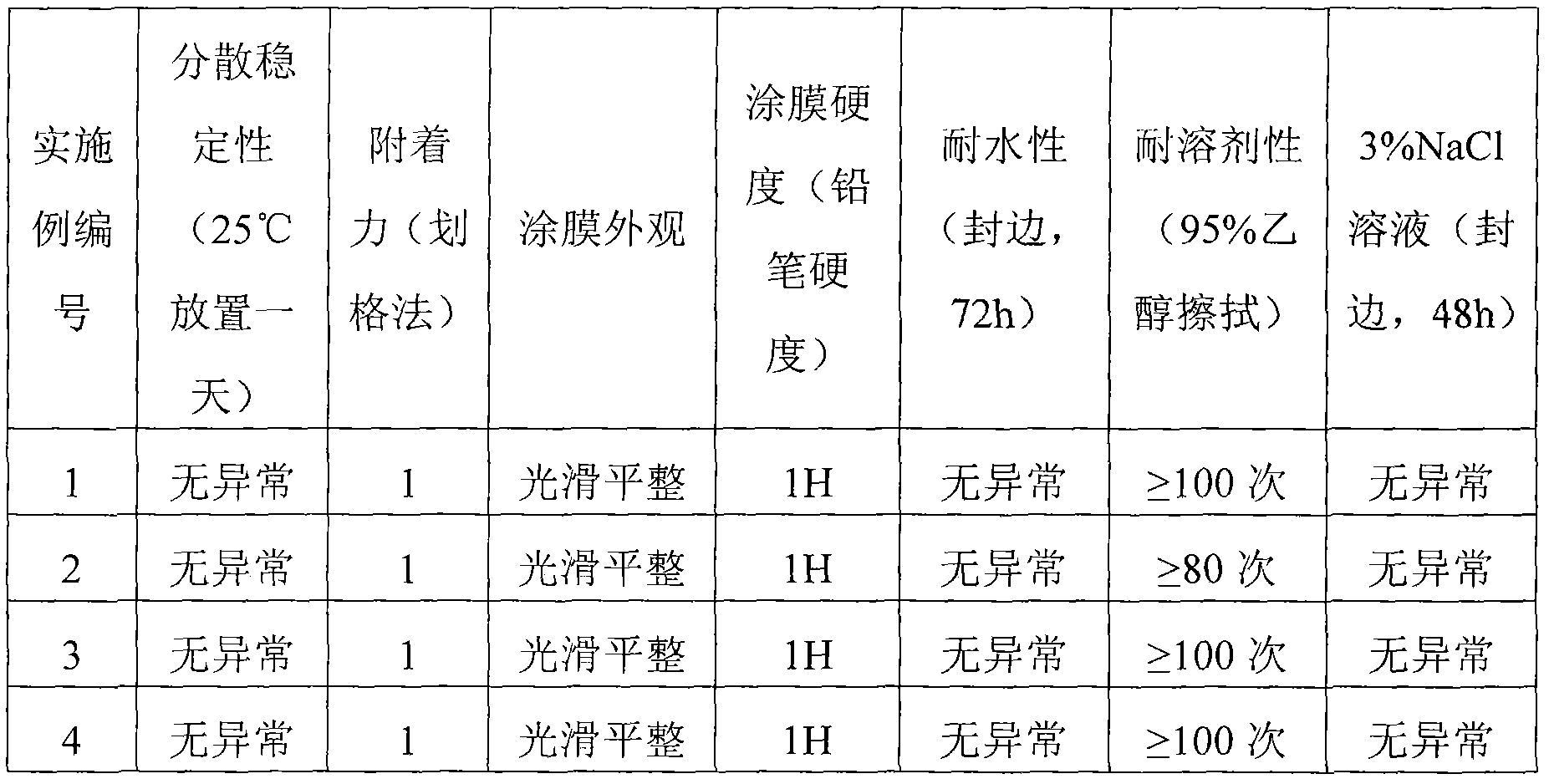

Examples

preparation example Construction

[0038]The preparation of the dispersion adopts the method of free radical solution polymerization. First, the temperature of the low-carbon alcohol is raised to slowly reflux, and then 10-20% by mass of the monomer, the initiator, and the molecular weight regulator are uniformly mixed and added to it, and the heat preservation is carried out. Half an hour later, add the remaining mixed monomers, initiators, and molecular weight regulators evenly in about 4 hours to obtain a water-soluble acrylic resin, and then add an organic amine neutralizer for neutralization. The degree of neutralization is 50-100%, preferably 100%, and the neutralization temperature is 30-100°C. Appropriate heating is beneficial to the dissolution of the polymer in the solvent, and the neutralization time is shortened. It is further preferably 50-70°C. Phase inversion and disperse in deionized water after salt formation to form a resin dispersion; the acid value of the dispersion is 20-100 mgKOH / g in terms...

Embodiment 1

[0046] Example 1: 11.60g methyl methacrylate, 11.00g butyl acrylate, 9.00g n-butyl methacrylate, 6.00g acrylate-2-ethylhexyl, 9.00g acrylate-2-hydroxypropyl, 21.00 g of trifluoroethyl methacrylate, 1.50 g of silicone monomer (A-172), 6.00 g of methacrylic acid, 1.50 g of azobisisobutyronitrile, and 0.40 g of mercaptoethanol were mixed and stirred to dissolve evenly. In addition, 21.00 g of a mixed solvent of absolute ethanol and n-butanol mixed in a ratio of 2:1 was added to a four-necked flask equipped with a stirrer, a condenser, a thermometer, and a dropping funnel, and heated in a water bath until the solvent was refluxed stably. Take 20% of the mixed monomer solution and put it into a four-necked flask, keep it warm at 82° C. for 0.5 hour, and then add the remaining monomer mixed solution uniformly dropwise at constant temperature for 3 hours. After 1 hour of heat preservation, add 0.15g of azobisisobutyronitrile (dissolved in 1g of n-butanol), continue heat preservation ...

Embodiment 2

[0049] Example 2: 9.00g methyl methacrylate, 11.00g butyl acrylate, 5.00g tertiary vinyl carbonate (VV-10), 6.00g acrylonitrile, 6.00g n-butyl methacrylate, 6.00g acrylic acid-2 -Ethylhexyl ester, 9.00g-2-hydroxypropyl acrylate, 15.00g trifluoroethyl methacrylate, 1.50g silicone monomer (A-172), 7.50g methacrylic acid, 1.60g azobisiso Butyronitrile and 0.40 g of mercaptoethanol were mixed and stirred to dissolve evenly. In addition, 22.00 g of a mixed solvent of isopropanol and n-butanol mixed in a ratio of 2:1 was added to a four-neck flask equipped with a stirring paddle, a condenser, a thermometer, and a dropping funnel, and heated in a water bath until the solvent was refluxed stably. Take 20% of the mixed monomer solution and put it into a four-necked flask, keep it warm at 90° C. for 0.5 hour, and then add the remaining monomer mixed solution uniformly dropwise at constant temperature for 3 hours. After 1 hour of heat preservation, add 0.16g of azobisisobutyronitrile (d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com