Separator for secondary cell

A technology for secondary batteries and separators, applied in the field of separators for secondary batteries, can solve the problems of shrinkage of organic separators, expansion of short-circuited parts, etc., and achieve high-efficiency manufacturing, excellent adhesion and anti-blocking properties, and high-temperature cycling. Excellent effect of characteristics and rate characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0297] (Manufacture of adhesive for heat-resistant layer)

[0298] 70 parts of ion-exchanged water, 0.15 parts of sodium lauryl sulfate (manufactured by Kao Chemical Co., Ltd., product name "Emal2F") as an emulsifier, and 0.5 parts of ammonium persulfate were respectively supplied to a reactor equipped with a stirrer, and the gas phase part was replaced with nitrogen. , heated up to 60°C.

[0299] On the other hand, in another container, 50 parts of ion-exchanged water, 0.5 parts of sodium dodecylbenzenesulfonate as a dispersant, 94.8 parts of butyl acrylate as a polymerizable monomer, 2 parts of acrylonitrile, and 1 part of acrylic acid, 1.2 parts of N-methylol acrylamide and 1 part of allyl glycidyl ether (AGE) to obtain a monomer mixture. This monomer mixture was continuously added to the above-mentioned reactor over 4 hours to perform polymerization. During the addition, the reaction was performed at 60°C. After completion of the addition, the reaction was further termi...

Embodiment 2

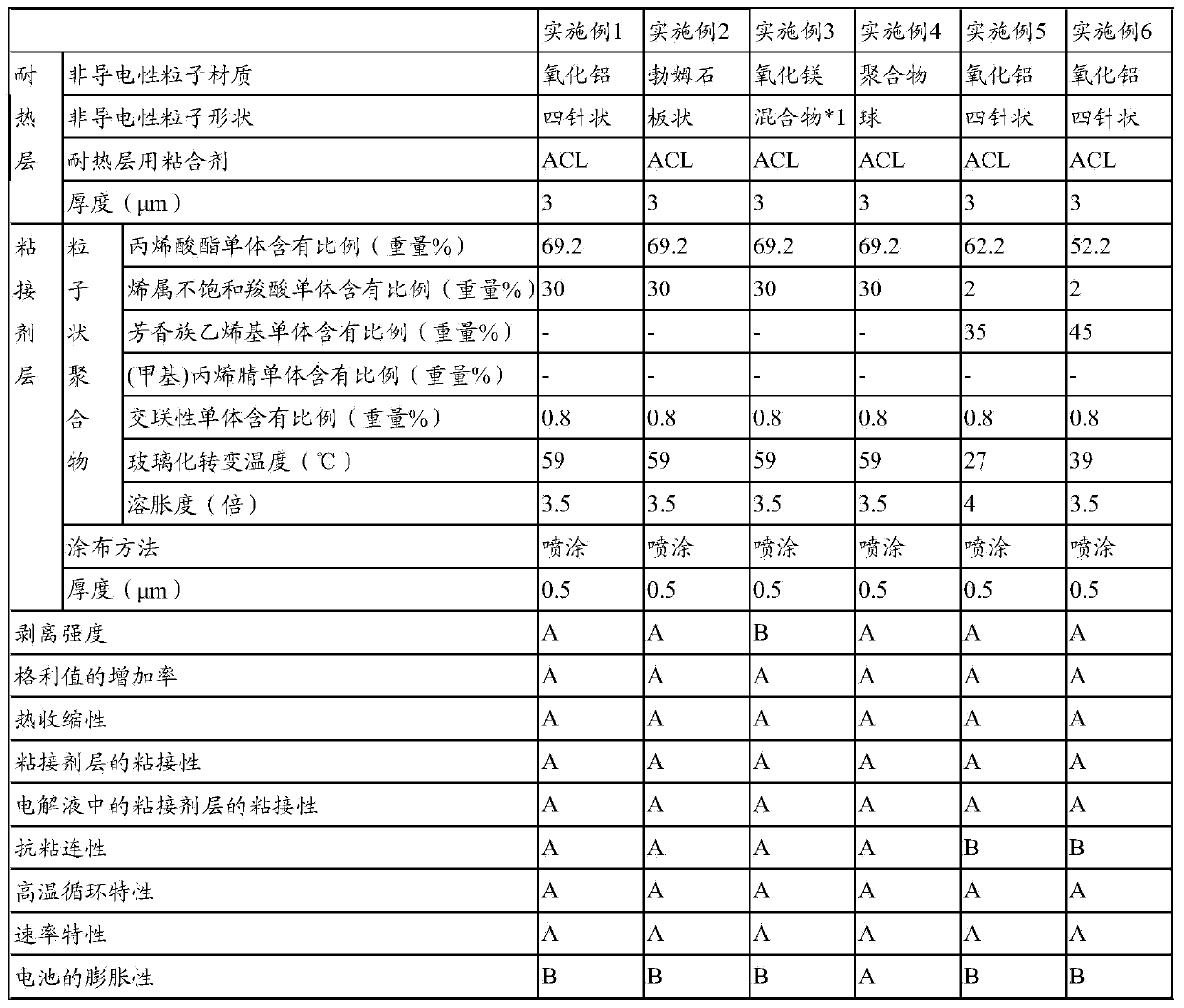

[0326] When producing the slurry for heat-resistant layers, boehmite particles (APYRAL AOH60 manufactured by Nabaltec Corporation, volume average particle diameter D50=0.9 μm, plate-shaped particles) were used as non-conductive particles. Other than that, it carried out similarly to Example 1, the slurry for heat-resistant layers, the slurry for adhesive bond layers, the separator for secondary batteries, and a secondary battery were manufactured, and each evaluated. The results are shown in Table 1.

Embodiment 3

[0328] When manufacturing the slurry for the heat-resistant layer, as the non-conductive particles, magnesium hydroxide (manufactured by Kamijima Chemical Industry Co., Ltd., volume average particle diameter D50=1.2 μm, ellipsoidal particles and polyhedrons with rounded corners) was used. mixture of shaped particles). Other than that, it carried out similarly to Example 1, the slurry for heat-resistant layers, the slurry for adhesive bond layers, the separator for secondary batteries, and a secondary battery were manufactured, and each evaluated. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com