Preparation method of composite microgel with temperature, pH and magnetic field sensitivities

A microgel, sensitive technology, applied in the field of materials, to achieve the effect of simple operation, reasonable design, extensive research and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

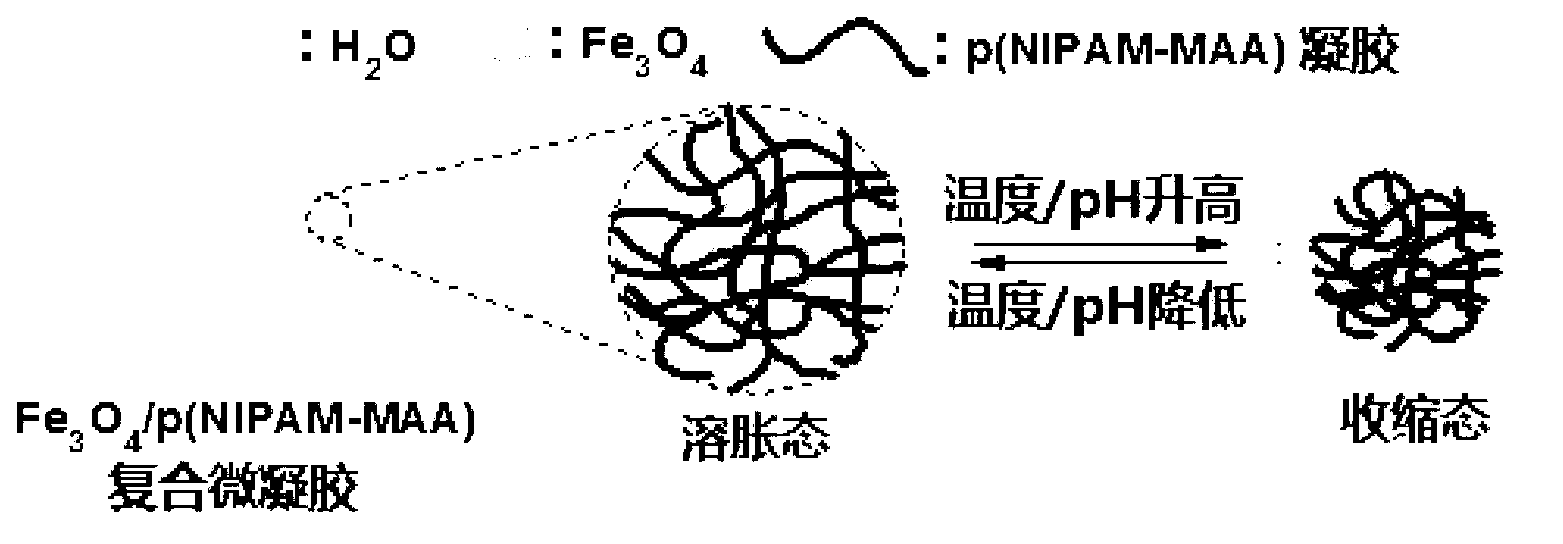

[0024] The structure of the composite microgel with triple sensitivity to temperature, pH and magnetic field and the process of swelling state / shrinking state adjusted by temperature / pH can be found in figure 1 , the detailed preparation steps are as follows: Dissolve 0.2mol ferric chloride, 0.1mol ferrous sulfate and 0.3mol thioglycolic acid in 100mL deionized water, raise the temperature to 60°C under magnetic stirring, add NaOH solution dropwise to adjust the reaction system If the pH is 7.5, a large number of black iron ferric oxide nanoparticles are obtained, and the temperature is raised to 80°C for aging for 30 minutes, then high-speed centrifugation, repeated washing, and vacuum drying to obtain dry powder of magnetic particles. Weigh 10 mg of magnetic particle dry powder and dissolve it in 100 mL of deionized water, add 20 mg of potassium persulfate, pass nitrogen gas for 30 min, raise the temperature to 70 °C under magnetic stirring and keep it for 10 min. Finally, 1...

Embodiment 2

[0027] The detailed preparation steps are as follows: Dissolve 0.3mol ferric chloride, 0.2mol ferrous sulfate and 0.5mol thioglycolic acid in 100mL deionized water, raise the temperature to 75°C under magnetic stirring, add NaOH solution dropwise to adjust the reaction system to When the pH is 8.0, a large amount of black iron ferric oxide nanoparticles are obtained, and the temperature is raised to 85°C for aging for 30 minutes, then centrifuged at a high speed, washed repeatedly, and dried in vacuum to obtain dry powder of magnetic particles. Weigh 15 mg of magnetic particle dry powder and dissolve it in 100 mL of deionized water, add 25 mg of potassium persulfate, pass nitrogen gas for 30 min, raise the temperature to 75 °C under magnetic stirring and keep it for 10 min. Finally, 15 mL of a mixed aqueous solution in which 150 mg of N-isopropylacrylamide, 15 mg of methacrylic acid, 15 mg of N, N-methylenebisacrylamide and 15 mg of sodium lauryl sulfate were dissolved was adde...

Embodiment 3

[0029] The detailed preparation steps are as follows: Dissolve 0.2mol ferric chloride, 0.2mol ferrous sulfate and 0.4mol thioglycolic acid in 100mL deionized water, raise the temperature to 70°C under magnetic stirring, add NaOH solution dropwise to adjust the reaction system to When the pH is 7.5, a large amount of black iron ferric oxide nanoparticles is obtained, and the temperature is raised to 80°C for aging for 30 minutes, then centrifuged at a high speed, washed repeatedly, and dried in vacuum to obtain dry powder of magnetic particles. Weigh 10 mg of magnetic particle dry powder and dissolve it in 10 mL of deionized water, add 20 mg of potassium persulfate, pass nitrogen gas for 30 min, raise the temperature to 75 °C under magnetic stirring and keep it for 10 min. Finally, 25 mL of a mixed aqueous solution in which 200 mg of N-isopropylacrylamide, 20 mg of methacrylic acid, 20 mg of N, N-methylenebisacrylamide and 20 mg of sodium lauryl sulfate were dissolved was added,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com