Surface treatment method of special nanometer calcium carbonate for polyurethane sealant

A polyurethane sealant and nano-calcium carbonate technology, which is applied in the direction of inorganic pigment treatment, dyeing physical treatment, chemical instruments and methods, etc., can solve the problem that nano-calcium carbonate cannot meet the production requirements of high-quality polyurethane sealant, and modifiers are easy to precipitate, etc. problems, to achieve the effect of weakening the macroscopic phase separation, shortening the dry time, and promoting the microphase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Preparation of nano calcium carbonate slurry:

[0033] Limestone with a CaCO3 content greater than 98.5% is calcined at 1050°C for 3 hours to obtain quicklime; quicklime and water are fully digested at a temperature of 70±5°C at a weight ratio of 1:5 to obtain slaked lime slurry; the lime slurry is sieved to remove slag, and water is added Dilute to a Ca(OH)2 solid content of 10-12%, control the freezing temperature at 15-22°C; pass lime kiln gas with a CO2 volume concentration of 28-33% into the lime slurry to react until the system pH<7.5 to prepare nano-calcium carbonate slurry. The dry powder of the nano-calcium carbonate slurry used in the embodiment of the present invention has a specific surface area of 25-35 m2 / g, and has a cubic-like regular shape.

Embodiment 1

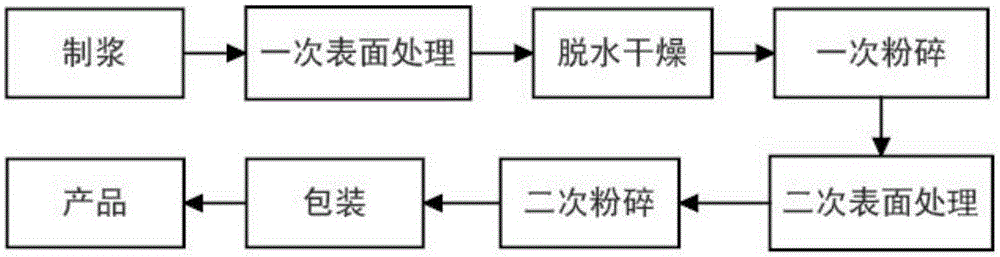

[0035] according to figure 1 The process flow shown is to process the nano-calcium carbonate slurry. The newly prepared pH is 6.8, BET specific surface area is 25.3m 2 / g, mass concentration is that 10% nano-calcium carbonate suspension is added in the reaction kettle, start agitator, pass into water vapor heating temperature to 75 ℃, constant temperature; Add 2.5% (calcium carbonate dry basis mass) fatty acid and lysine The mixed saponification solution of acid, wherein the mass ratio of fatty acid and lysine is 1:1, the fatty acid is stearic acid, the saponification agent is sodium hydroxide, and its addition is 17% of the total weight of fatty acid and lysine, stirring 40 minutes to complete the first surface treatment. The treated nano-calcium carbonate slurry is squeezed and dried with a chain-belt dryer, and the moisture content of the dried material is lower than 0.28%. The dried material is pulverized by a pin mill pulverizing device to obtain the primary product na...

Embodiment 2

[0038] according tofigure 1 The process flow shown is to process the nano-calcium carbonate slurry. The newly prepared pH is 6.8, BET specific surface area is 31.2m 2 / g, the nanometer calcium carbonate suspension that mass concentration is 10% is added in the reaction kettle, start agitator, pass into water vapor heating temperature to 75 ℃, constant temperature; Then add 3.0% (calcium carbonate dry basis) fatty acid and lysine Mixed saponification solution of acid, wherein the mass ratio of fatty acid and lysine is 1:1, the fatty acid is stearic acid, the saponification agent is sodium hydroxide, and its addition is 17% of the total weight of fatty acid and lysine, stirred for 40 Minutes to complete the first surface treatment. The treated nano-calcium carbonate slurry is squeezed and dried with a chain-belt dryer, and the moisture content of the dried material is lower than 0.28%. The dried material is crushed and classified by a pin mill crushing equipment to obtain the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com