Pesticide suspension concentrate dispersing agent and novel preparation method thereof

A technology of dispersant and suspending agent, applied in the field of high-efficiency pesticide suspending agent and dispersing agent and its preparation method, which can solve the problems of high cost and dependence on imports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

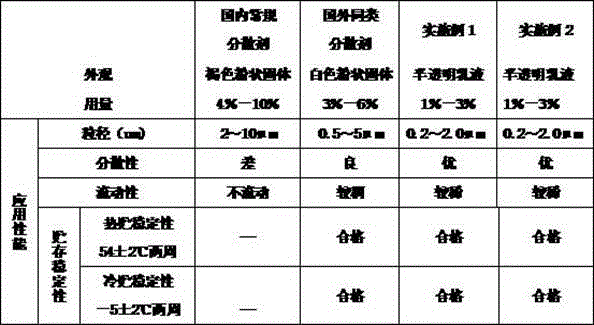

Examples

Embodiment 1

[0036] Add 50.8g MA-1, 25.5g MB-1, 23.7g MC-1, 16.8g NaOH, 0.1g acrylamide, 20g SF-1 to a four-necked flask equipped with a stirrer, dropping funnel, thermometer and condenser and 244g of water, stir and heat up to 60°C, turn on the N 2 protection, and then began to slowly drop 25ml of potassium persulfate aqueous solution with a concentration of 1.5wt%, controlling the dropping time within 4h, and the reaction temperature at 58-62°C. After the initiator was added dropwise, the temperature was raised to 90°C to continue the reaction for 2 hours. 2 After cooling down to room temperature, evacuate to 480mmHg to remove unreacted monomers and small molecule polymers to obtain the pesticide suspension and dispersant of the present invention.

[0037]

Embodiment 2

[0039] Add 50.8g MA-1, 33.5g MB-2, 15.7g MC-2, 22.1g NaOH, 0.1g acrylamide, 20g SF-2 to a four-necked flask equipped with a stirrer, dropping funnel, thermometer and condenser and 244g of water, stir and heat up to 60°C, turn on the N 2protection, and then began to slowly drop 25ml of azoamidine aqueous solution with a concentration of 1.5wt%, controlling the dropping time within 4h, and the reaction temperature at 58-62°C. After the initiator was added dropwise, the temperature was raised to 80°C to continue the reaction for 2.5 hours. 2 After cooling down to room temperature, evacuate to 480mmHg to remove unreacted monomers and small molecule polymers to obtain the pesticide suspension and dispersant of the present invention.

[0040]

Embodiment 3

[0042] Add 50.8g of MA-1, 33.5g of MB-2, 20g of SF-2, 22.1g of NaOH and 244g of water into a four-neck flask equipped with a stirrer, dropping funnel, thermometer and condenser tube, stir to raise the temperature to 60°C, and open N 2 protection, then start to slowly add 8ml of azoamidine aqueous solution with a concentration of 1.5wt%, then add 15.7g MC-2 and 0.1g acrylamide, continue to dropwise add 17ml of initiator, control the dropping time within 4h, and the reaction temperature is at 58~62℃. After the initiator was added dropwise, the temperature was raised to 90°C to continue the reaction for 2 hours. 2 After cooling down to room temperature, evacuate to 480mmHg to remove unreacted monomers and small molecule polymers to obtain the pesticide suspension and dispersant of the present invention.

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com