Method for preparing hydroxy-containing polyacrylate secondary aqueous dispersion

A technology of hydroxyl polyacrylate and acrylate, which is used in the synthesis of raw materials for water-based coatings, the preparation of secondary aqueous dispersions of hydroxyl-containing polyacrylates, and the field of water-based coatings, which can solve the problems of poor stability, high viscosity, and secondary acrylates. High acid value of the dispersion, to achieve the effect of fast surface drying speed and low acid value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

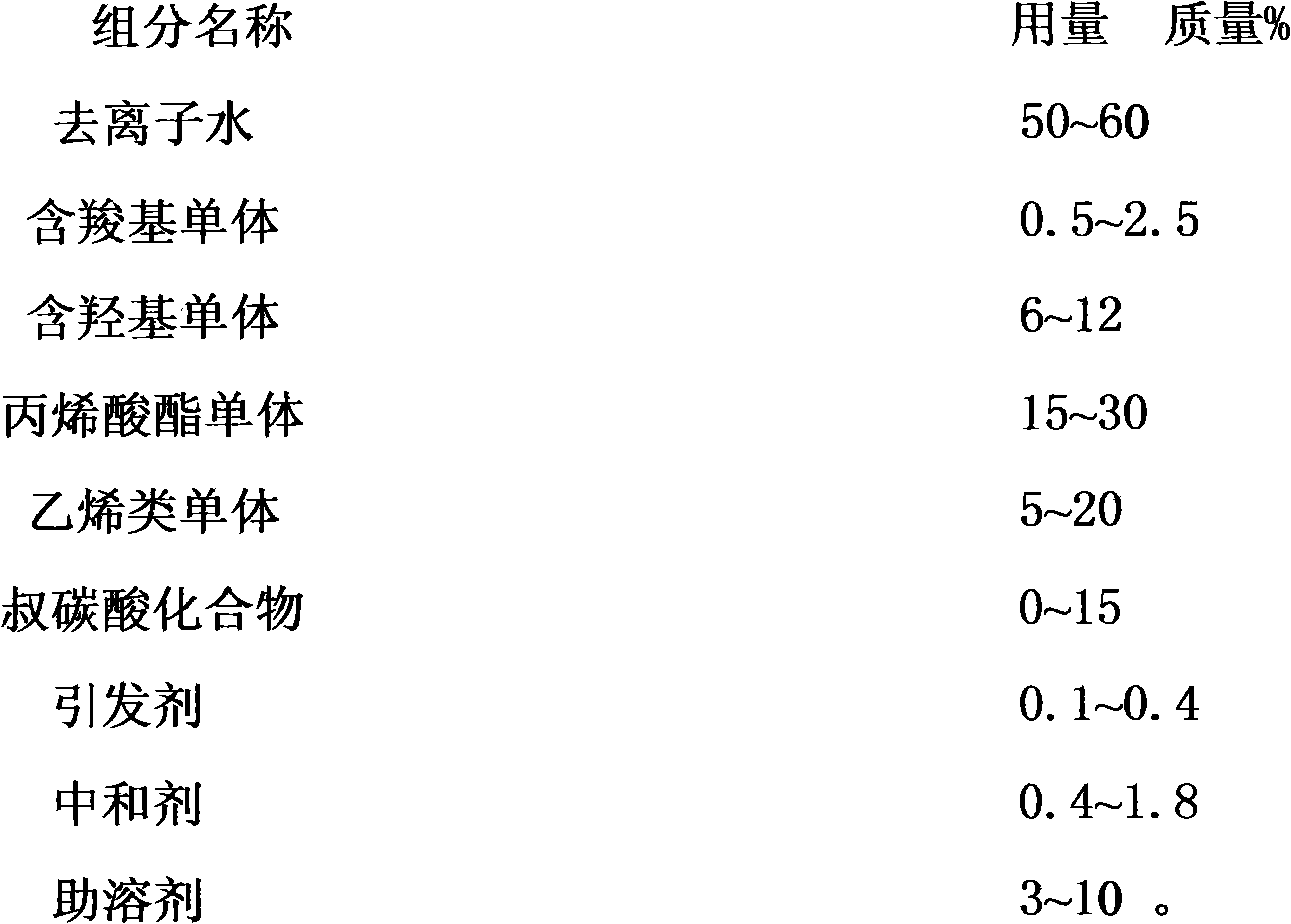

Method used

Image

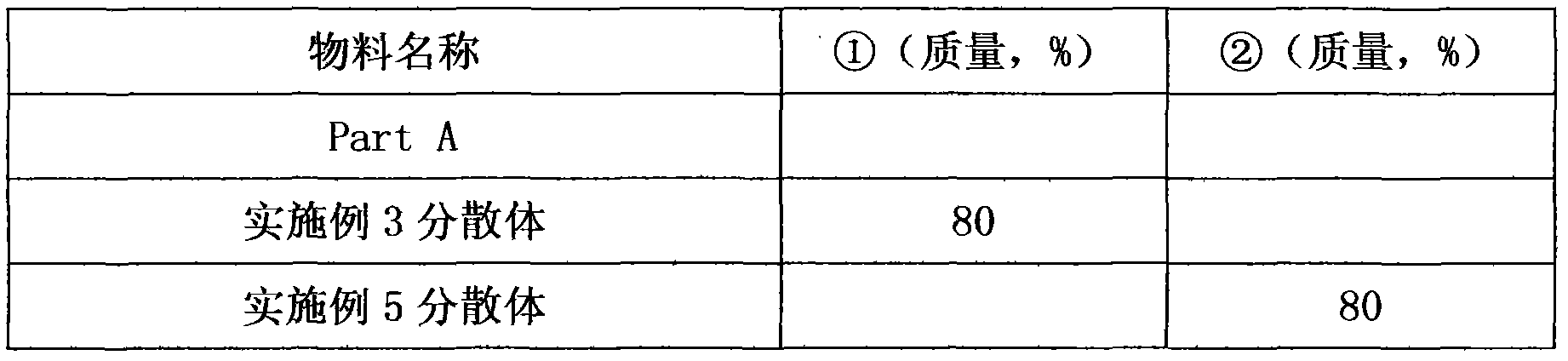

Examples

Embodiment 1

[0038] Add the mixture of 32g propylene glycol butyl ether and 32g Solvesso 100 into the reactor, blow nitrogen, stir and raise the temperature to 116-122°C, start to drop 60.1g methyl methacrylate, 56g styrene, 60g hydroxyethyl methacrylate , a mixture of 19.6g n-butyl methacrylate, 60g butyl acrylate and 9g tert-butyl peroxybenzoate, control the rate of addition uniformly, drop the mixture in about 3 hours, and immediately start adding 28.2g methyl The mixture of methyl acrylate, 30g hydroxyethyl methacrylate, 23g butyl acrylate, 8.8g acrylic acid and 3.7g tert-butyl peroxybenzoate was added dropwise at a constant speed, and the dripping was completed within 1h30min. After keeping warm for 30min, add 1.3 g tert-butyl peroxybenzoate, continue to keep warm for 2-3 hours, cool down to 80°C, add 9.8g dimethylethanolamine, stir for 20min, add 366.5g deionized water at a uniform speed within 1h, stir and disperse, and obtain milky white translucent water dispersion. After testing...

Embodiment 2

[0042] Add the mixture of 40g propylene glycol butyl ether and 36g VeoVa 10 (a kind of highly branched tertiary carbonic acid ethylene ester produced by Shell Company) into the reactor, blow nitrogen, stir and raise the temperature to 116~122°C, start to drop 30g methyl A mixture of methyl acrylate, 36g styrene, 88g hydroxypropyl methacrylate, 25g n-butyl methacrylate, 32g butyl acrylate and 8.8g tert-butyl peroxybenzoate, control the rate of addition uniformly, in about 3h The mixture was dropped, and immediately after the drop, the mixture of 25.8g methyl methacrylate, 43g hydroxypropyl methacrylate, 20.6g butyl acrylate, 9.3g acrylic acid and 3.9g tert-butyl peroxybenzoate was added dropwise at a constant speed Add dropwise, finish dropping within 1h30min, after keeping warm for 30min, add 1.3g of tert-butyl peroxybenzoate, continue keeping warm for 2-3h, cool down to 80°C, add 11.1g of dimethylethanolamine, stir for 20min, after 1h Add 443.8 g of deionized water at a const...

Embodiment 3

[0046] Add the mixture of 32g propylene glycol butyl ether and 32g Solvesso 100 into the reactor, blow nitrogen, stir and raise the temperature to 134-140°C, start to add 60.1g methyl methacrylate, 56g styrene, 60g hydroxyethyl methacrylate dropwise , the mixture of 19.6g n-butyl methacrylate, 60g butyl acrylate and 9.2g di-tert-butyl peroxide, control the rate of addition uniformly, drop the mixture within 3h, start to drop 28.2g formazan immediately after dropping The mixture of methyl methacrylate, 30g hydroxyethyl methacrylate, 23g butyl acrylate, 8.8g acrylic acid and 3.8g di-tert-butyl peroxide was added dropwise at a constant speed, and the dripping was completed within 1h30min. After keeping warm for 30min, additional 1.3g of di-tert-butyl peroxide, continue to keep warm for 2~3h, cool down to 80°C, add 9.8g of dimethylethanolamine, stir for 20min, add 366.2g of deionized water at a uniform speed within 1h, stir to disperse, and obtain milky white half Transparent aque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com