Preparation method of matting leather water-based polyurethane coating agent

A water-based polyurethane self-dulling technology, applied in polyurea/polyurethane coatings, leather surface treatment, small raw leather/big raw leather/leather/fur treatment, etc., can solve problems such as insufficient color brightness, air pollution, poor compatibility, etc. , to achieve the effect of solving the problem of storage stability, good light stability, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation method of self-dulling type leather waterborne polyurethane finishing agent, preparation method is as follows:

[0038] A Preparation of Polyurethane Component A

[0039] a) Mix isocyanate trimer, diisocyanate, small molecule hydrophilic monomer, macromolecular diol monomer and catalyst, and react at 60°C for 8 hours;

[0040] b) The temperature of the reaction solution was lowered to 30°C, and triethylamine was added, and reacted for 30 minutes;

[0041] c) Add deionized water, stir and disperse for 2 hours to obtain water-based polyurethane component A emulsion;

[0042] B Preparation of Polyurethane Component B

[0043] a) Mix aliphatic diisocyanate, small molecule hydrophilic monomer, macromolecular diol monomer and catalyst, and react at 60°C for 8 hours;

[0044] b) The temperature of the reaction solution was lowered to 30°C, and triethylamine was added, and reacted for 30 minutes;

[0045] c) Add deionized water, stir and disperse for 2 hours...

Embodiment 2

[0049] The preparation method of self-dulling type leather waterborne polyurethane finishing agent, preparation method is as follows:

[0050] A Preparation of Polyurethane Component A

[0051] a) Mix isocyanate trimer, diisocyanate, small molecule hydrophilic monomer, macromolecular diol monomer and catalyst, and react at 90°C for 2 hours;

[0052] b) The temperature of the reaction solution was lowered to 50°C, and triethylamine was added, and reacted for 10 minutes;

[0053] c) Add deionized water, stir and disperse for 0.5 hour to obtain water-based polyurethane component A emulsion;

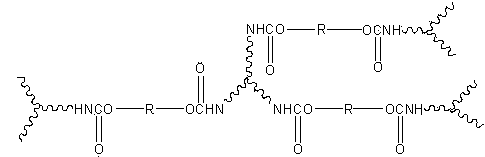

[0054] The molecular segment structure of component A is as follows:

[0055]

[0056] Wherein, R is a linear alkyl group.

[0057]

[0058] B Preparation of Polyurethane Component B

[0059] a) Mix aliphatic diisocyanate, small molecule hydrophilic monomer, macromolecular diol monomer and catalyst, and react at 90°C for 2 hours;

[0060] b) The temperature of the reaction solution ...

Embodiment 3

[0067] The preparation method of self-dulling type leather waterborne polyurethane finishing agent, preparation method is as follows:

[0068] A Preparation of Polyurethane Component A

[0069] a) Mix isocyanate trimer, diisocyanate, small molecule hydrophilic monomer, macromolecular diol monomer and catalyst, and react at 70°C for 3 hours;

[0070] b) The temperature of the reaction solution was lowered to 40°C, triethylamine was added, and the reaction was carried out for 20 minutes;

[0071] c) Add deionized water, stir and disperse for 1 hour to obtain water-based polyurethane component A emulsion;

[0072] B Preparation of Polyurethane Component B

[0073] a) Mix aliphatic diisocyanate, small molecule hydrophilic monomer, macromolecular diol monomer and catalyst, and react at 75°C for 4 hours;

[0074] b) The temperature of the reaction solution was lowered to 45°C, triethylamine was added, and the reaction was carried out for 20 minutes;

[0075] c) Add deionized wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com