Hydroxypolyacrylate emulsion, and preparation method and application thereof

A technology of hydroxy polyacrylate and hydroxy acrylate, applied in the field of hydroxy polyacrylate emulsion and its preparation, can solve the problems of poor chemical resistance, residual fluorine-containing monomer, high price, etc., and achieve water resistance and chemical resistance. Excellent, solve poor chemical resistance, improve the effect of paint film appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

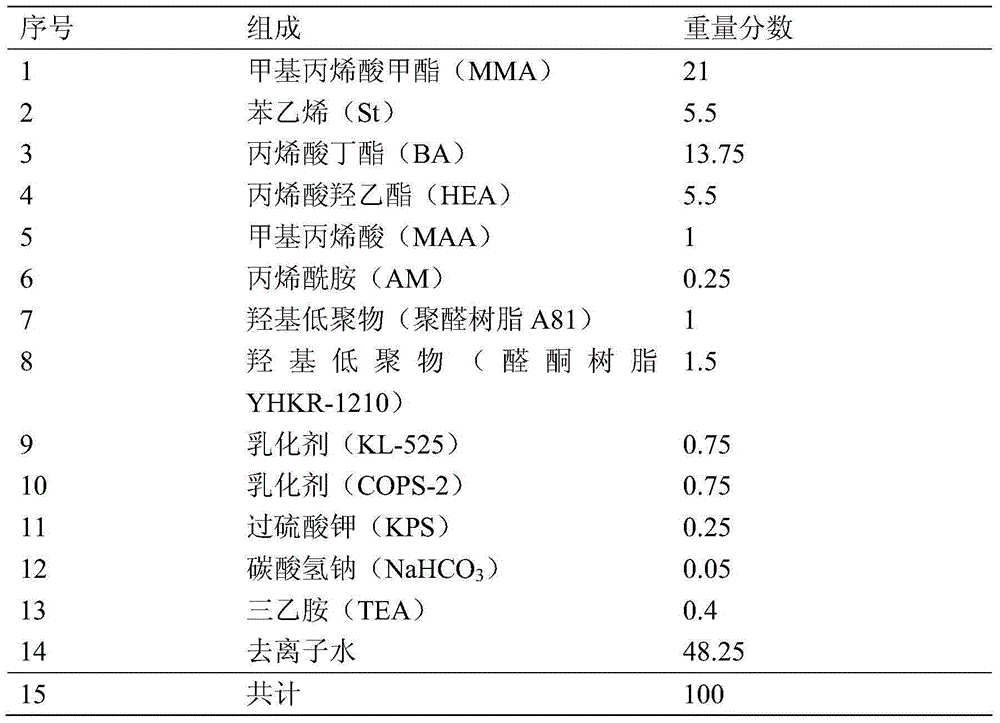

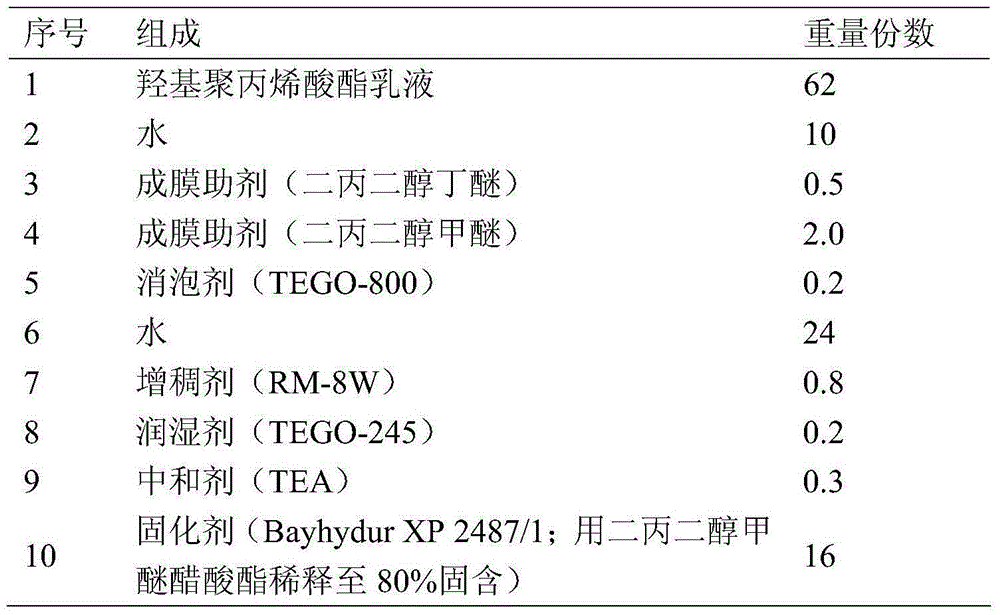

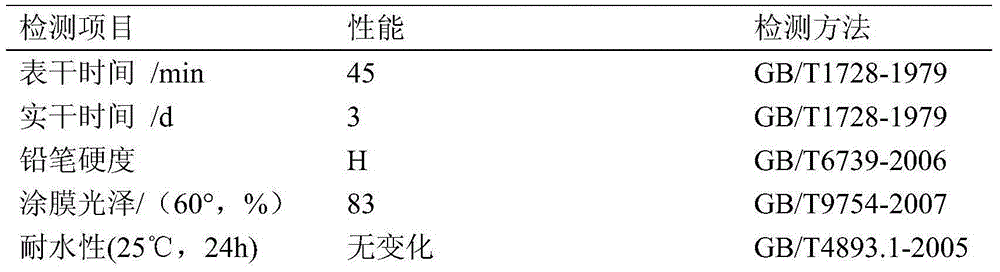

[0036] (1) Preparation of hydroxyl polyacrylate emulsion: the formula of hydroxyl polyacrylate emulsion (hydroxyl value=65mgKOH / g) is shown in Table 1a:

[0037] Table 1a

[0038]

[0039] Preparation process: Mix 1-9 to prepare monomer mixture, take 10% monomer mixture and pre-emulsify it with 0.05 parts of emulsifier (including 0.025 parts of KL-525 and 0.025 parts of COPS-2) and 2.75 parts of water as seed pre-emulsification liquid. Add the remaining emulsifier, sodium bicarbonate, 0.1 part of initiator (potassium persulfate), and 25 parts of deionized water into the reaction kettle, raise the temperature to 78°C, stir for 15 minutes, and drip the seed pre-emulsion within 20 minutes at a constant speed , and wait for the emulsion to be stable for half an hour to obtain the seed emulsion. Keep the temperature of the reaction system at 80°C. Mix the remaining mixed monomers with the rest of the monomers, then add dropwise to the seed emulsion, and at the same time add d...

Embodiment 2

[0052] (1) Preparation of hydroxyl polyacrylate emulsion: the formula of hydroxyl polyacrylate emulsion (hydroxyl value=65mgKOH / g) is shown in Table 2a:

[0053] Table 2a

[0054]

[0055] Preparation method: Mix 1-8 to prepare monomer mixture, take 15% of monomer mixture and dissolve it with 0.1 part of emulsifier (0.05 parts of SR-10 and ER-30) and 3 parts of water to pre-emulsify it as seed pre-emulsification liquid. Add the remaining emulsifier, sodium bicarbonate, 0.1 part of initiator (ammonium persulfate), and 30 parts of deionized water into the reaction kettle, raise the temperature to 80°C, stir for 30 minutes, and drip the seed pre-emulsion within 30 minutes at a constant speed , and wait for the emulsion to be stable for half an hour to obtain the seed emulsion. Keep the temperature of the reaction system at 80°C. Add the remaining monomer mixture dropwise to the seed emulsion, and at the same time add dropwise an aqueous solution in which 0.2 parts of the in...

Embodiment 3

[0067] (1) Preparation of hydroxyl polyacrylate emulsion: the formula of hydroxyl polyacrylate emulsion (hydroxyl value=70mgKOH / g) is shown in Table 3a:

[0068] Table 3a

[0069]

[0070] Preparation process: Mix 1-8 to prepare a monomer mixture, take 12% monomer mixture and pre-emulsify it with 0.1 part of emulsifier (0.05 parts of each of the two emulsifiers) and 3 parts of water as a seed pre-emulsion. Add the remaining emulsifier, sodium bicarbonate, 0.1 part of initiator (KPS), and 20 parts of deionized water into the reaction kettle, raise the temperature to 82°C, stir for 15 minutes, and drip the seed pre-emulsion at a constant speed within 15 minutes. The emulsion was stable for half an hour to obtain a seed emulsion. The temperature of the reaction system was kept at 82°C. Mix the remaining monomer mixture with the rest of the monomers, then add dropwise to the seed emulsion, and at the same time add dropwise an aqueous solution of 0.2 parts of initiator (KPS) d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com