Anti-icing and anti-frosting polyurethane coating and preparation method thereof

A polyurethane coating and anti-frosting technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor mechanical properties of film-forming substances, low adhesion to substrates, limitations, etc., achieve good hydrophobicity, improve hydrophobicity resistance, the effect of inhibiting the formation of initial frost crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

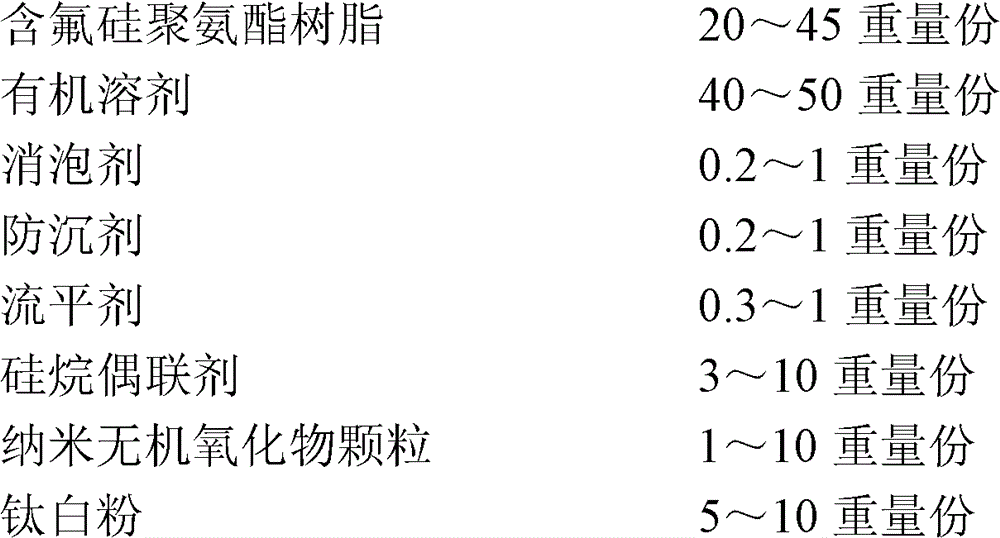

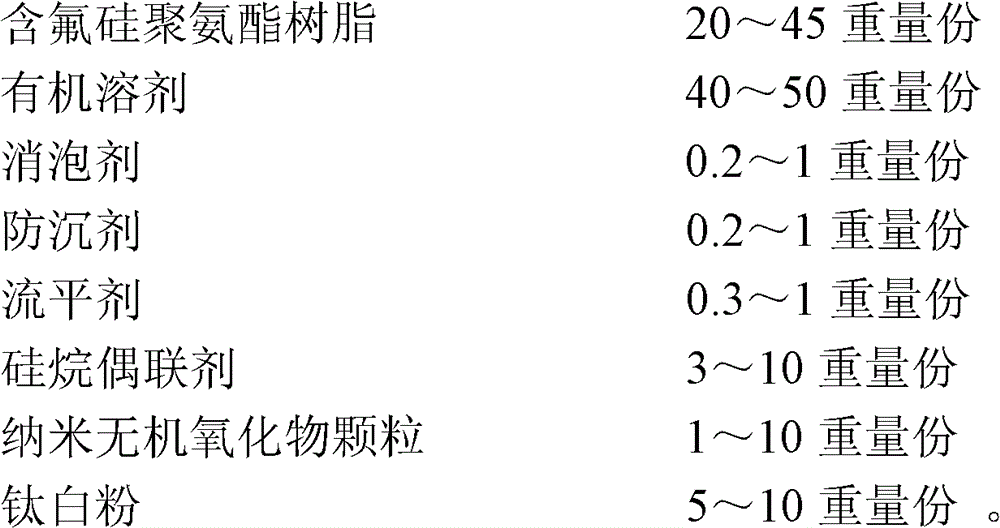

[0033] (1) At room temperature (25°C), 10 grams of ethylene-chlorotrifluoroethylene copolymer diol (number-average molecular weight is 1000), 10 grams of hydroxyl-terminated polydimethylsiloxane (number-average molecular weight is 1000), Add 30 grams of polyether diol (number average molecular weight is 1000), 10 grams of 2,4-toluene diisocyanate into the reaction kettle, heat up to 60°C, react for 3 hours, then add 1 gram of 1,4-butanediol , reacted for 2 hours, and discharged to obtain fluorine-containing silicon polyurethane resin.

[0034] (2) Get 20 grams of the above-mentioned fluorine-containing silicon polyurethane resin, 40 grams of ethyl acetate, 0.2 grams of 2,4,7,9-tetramethyl-5-decyne-4,7-diol, 0.2 grams of organic bentonite and 0.3 g of polyacrylate was stirred to prepare a mixed solution. Add 3 grams of γ-mercaptopropyltrimethoxysilane to the mixed solution and stir, then add 1 gram of silicon oxide with a particle size of 10 nm to 20 nm, and 5 grams of titaniu...

Embodiment 2

[0037](1) At room temperature, 15 grams of polyperfluoroethylene propylene glycol (number average molecular weight is 2500), 20 grams of hydroxyl-terminated polydimethylsiloxane (number average molecular weight is 2500), 35 grams of polyether glycol (Number average molecular weight is 2500), 17.5 grams of 4,4'-diphenylmethane diisocyanate was added to the reaction kettle, the temperature was raised to 75°C, and reacted for 4 hours, then 5.5 grams of diethylene glycol was added and reacted for 3 hours , and the fluorine-containing silicon polyurethane resin is obtained by discharging.

[0038] (2) Take 32.5 grams of the above-mentioned fluorine-containing silicon polyurethane resin, 45 grams of propylene glycol methyl ether propionate, 0.6 grams of 3,6-dimethyl-4-octyne-3,6-diol, 0.6 grams of modified polyamide Wax powder and 0.65 g of fluorine-modified polyacrylate were stirred to prepare a mixed solution. Add 6.5 grams of 3-glycidyl etheroxypropyltrimethoxysilane to the abov...

Embodiment 3

[0041] (1) At room temperature, 20 grams of tetrafluoroethylene-perfluoroalkyl vinyl ether copolymer diol (number-average molecular weight is 4000), 30 grams of hydroxyl-terminated polydimethylsiloxane (number-average molecular weight is 4000) , 40 gram polyether diols (number-average molecular weight is 4000), 25 gram xylylene diisocyanates join in the reactor, be warming up to 90 ℃, react for 5 hours, then add 10 gram neopentyl glycol, react After 4 hours, the fluorine-containing silicon polyurethane resin was obtained by discharging.

[0042] (2) Take 45 grams of the above-mentioned fluorine-containing silicon polyurethane resin, 50 grams of methyl isobutyl ketone, 1 gram of 3,5-dimethyl-1-hexyn-3-ol, 1 gram of zinc ricinoleate, 1 gram of The phosphate-modified polyacrylate is stirred and prepared into a mixed solution. Add 10 grams of 2-(3,4-epoxycyclohexyl)ethyltriethoxysilane to the above mixed solution and stir, then add 10 grams of titanium dioxide with a particle siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com