Water-proof, cold-proof and moisture permeable polyurethane coating cloth and its producing process

A polyurethane coating and polyurethane technology, applied in the direction of textiles and papermaking, etc., can solve the problems that are difficult to meet the requirements of the military and tourists for special functions such as clothing waterproof, cold protection, moisture permeability, etc., thick fabrics, and no moisture permeability, etc., to achieve Good wind resistance and heat preservation performance, moisture-permeable carrying and sports, light and thin, easy to carry and sports effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

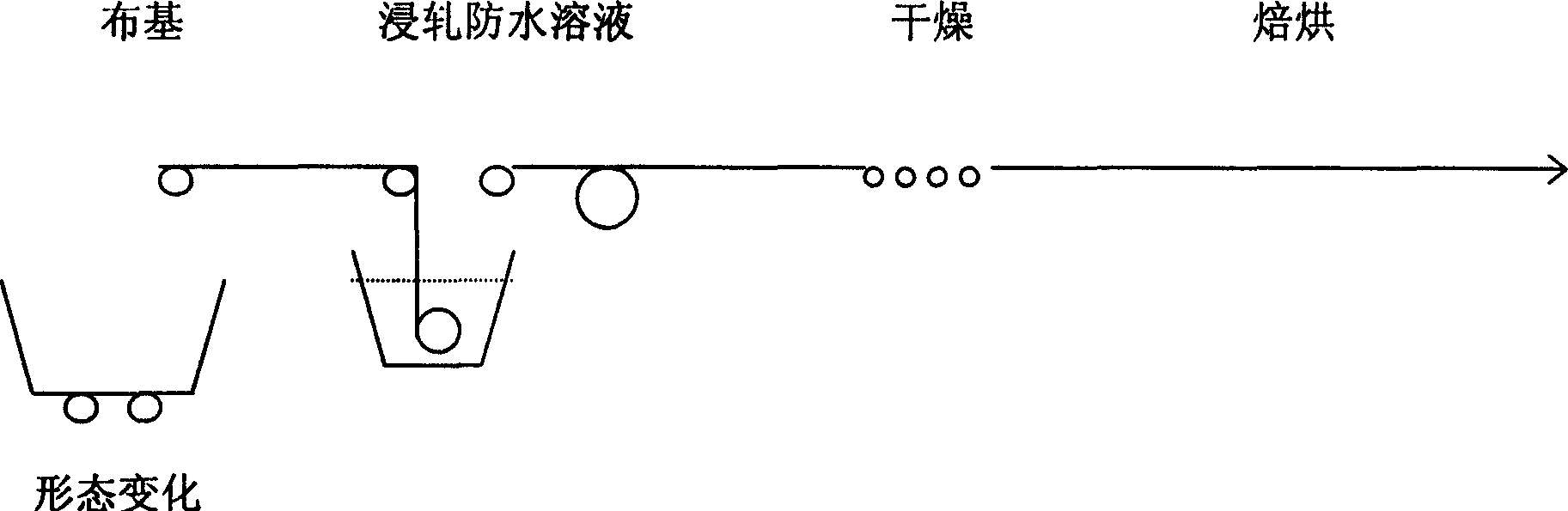

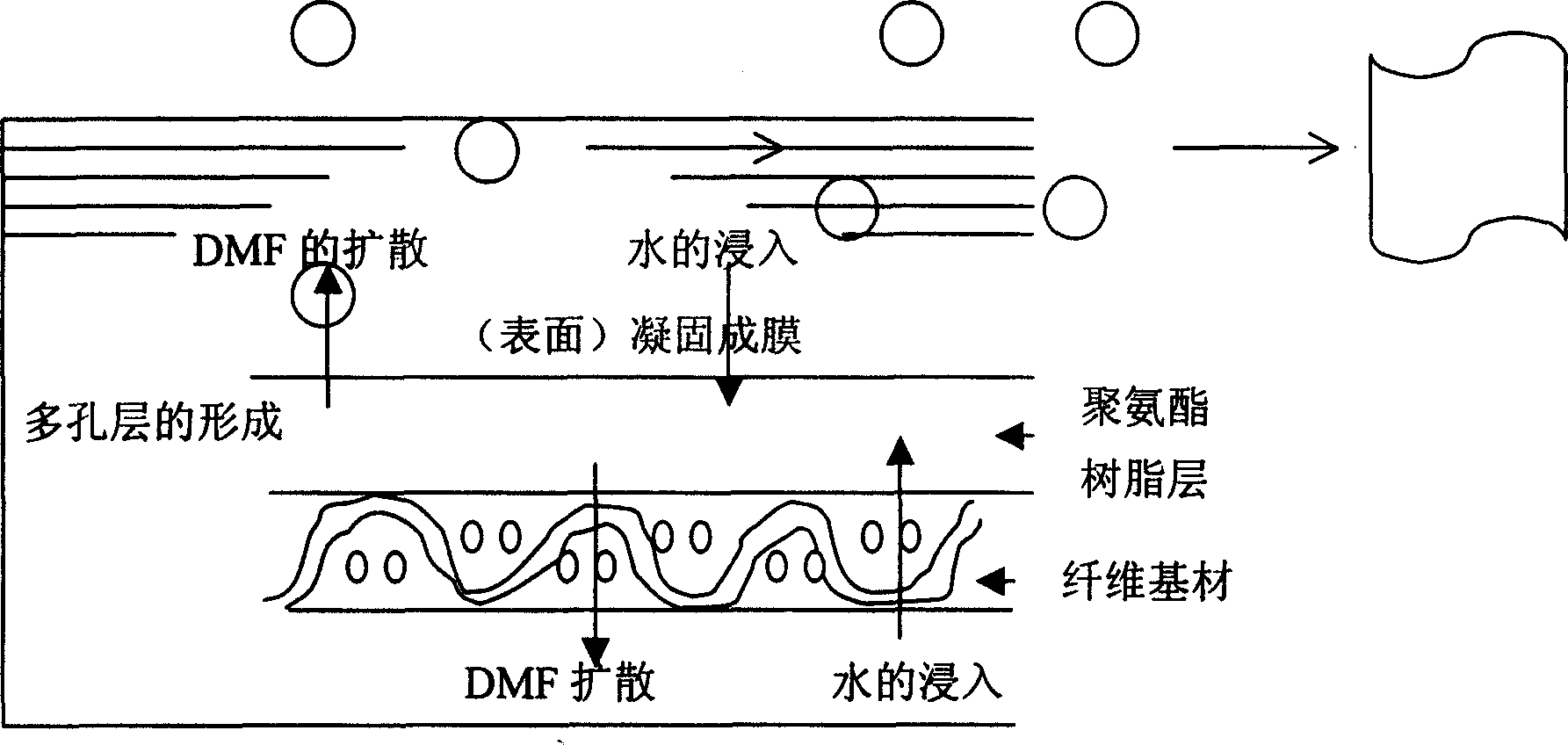

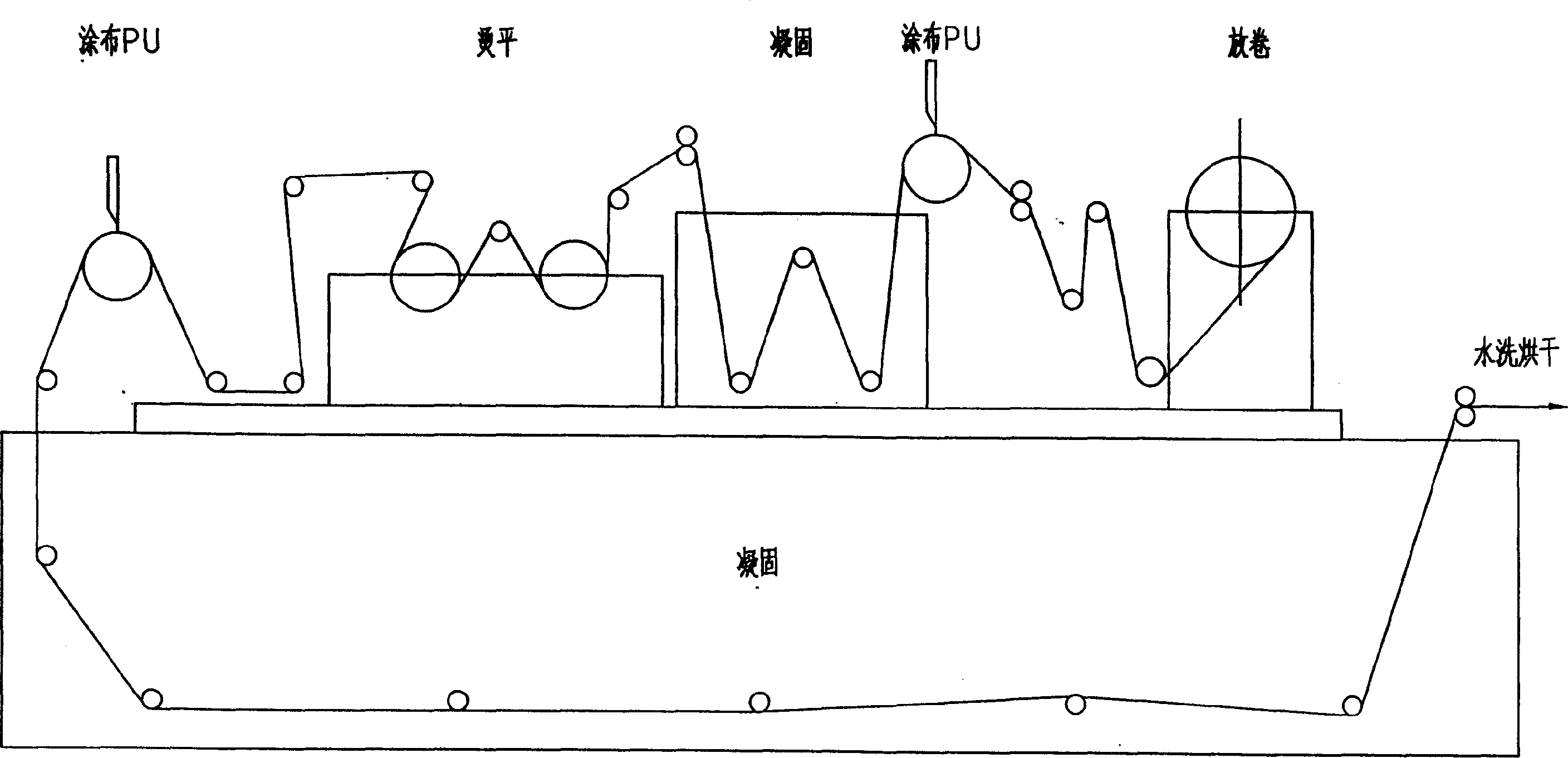

[0029] Made of polyester silk fabric, unwound for waterproofing. In the waterproof treatment liquid, 100 grams of soft water, 2 grams of fluorine-based waterproofing agent AG-480, 1 gram of isopropanol, and acetic acid is added to adjust the pH to 6. Then bake the impregnated cloth base at 140° C., dry for 3-5 minutes, and then wind up. Next, a wet film-forming process is performed. Unwind the waterproof treated cloth base, and coat the first layer of PU mixture, in which 100 grams of PU resin M-498, 30 grams of DMF, 1 gram of fluorine surface modifier F-3D, 1 gram of silicon dioxide, bridging Agent WD-40 2 g. After the coating is completed, solidify at room temperature for 8 seconds, and then iron it at 80°C. After ironing, apply the second layer of PU mixture, including 100 grams of PU resin M-498, 35 grams of DMF, 1 gram of fluorine surface modifier F-3D, 1 gram of accelerator S-901, and an appropriate amount of color paste (pigment). After coating, solidify for 3 minut...

Embodiment 2

[0031] Use polyester silk fabric, unwind for waterproof treatment, waterproof treatment solution, 100 grams of soft water, 4 grams of fluorine-based waterproofing agent YD-510A, 3 grams of isopropanol, add acetic acid to adjust the pH to 5. Then bake the impregnated cloth base at 160° C., dry for 3-5 minutes, and then wind up. Then carry out the wet film forming process, unwind the waterproof treated cloth base, and coat the first layer of PU mixed solution, wherein 100 grams of PU resin M-825, 40 grams of DMF, 3 grams of fluorine surface improver F-3D, 2 grams of silicon dioxide, 5 grams of bridging agent AD-8. After the coating is completed, solidify at room temperature for 10 seconds, and then iron it at 110°C. After ironing, apply the second layer of PU mixture, in which 100 grams of PU resin M-825, 40 grams of DMF, 3 grams of fluorine surface modifier F-3D, 2 grams of accelerator S-92, and appropriate amount of color paste (pigment). After coating, solidify for 5 minute...

Embodiment 3

[0033] Use polyester silk fabric, unwind for waterproof treatment, in the waterproof treatment solution, soft water is 100 grams, fluorine-based waterproofing agent SG-713 6 grams, isopropanol 4 grams, and glacial acetic acid is added to adjust the pH to 5. Then bake the impregnated cloth base at 180° C., dry for 3-5 minutes, and then wind up. Then carry out the wet film forming process, unwind the waterproof treated cloth base, and coat the first layer of PU mixed solution, wherein PU resin M-826 is 100 grams, DMF50 grams, fluorosurfactant F-3D 5 grams, 4 grams of silicon dioxide, 8 grams of bridging agent AD-7. After the coating is completed, solidify at room temperature for 15 seconds, and then iron it at 130°C. After ironing, apply the second layer of PU mixture, wherein 100 grams of PU resin M-826, 45 grams of DMF, 5 grams of fluorine surface modifier F-3D, 4 grams of accelerator S-92, and appropriate amount of color paste (pigment). After coating, solidify for 5 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com