Super-hydrophobic acrylic polyurethane coating and preparation method thereof

An acrylic polyurethane and super-hydrophobic technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of complex preparation process, unsuitable dip coating method, easy peeling of hydrophobic gel layer, etc., and achieve broad application prospects and preparation The method is simple and easy, and the effect of increasing durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

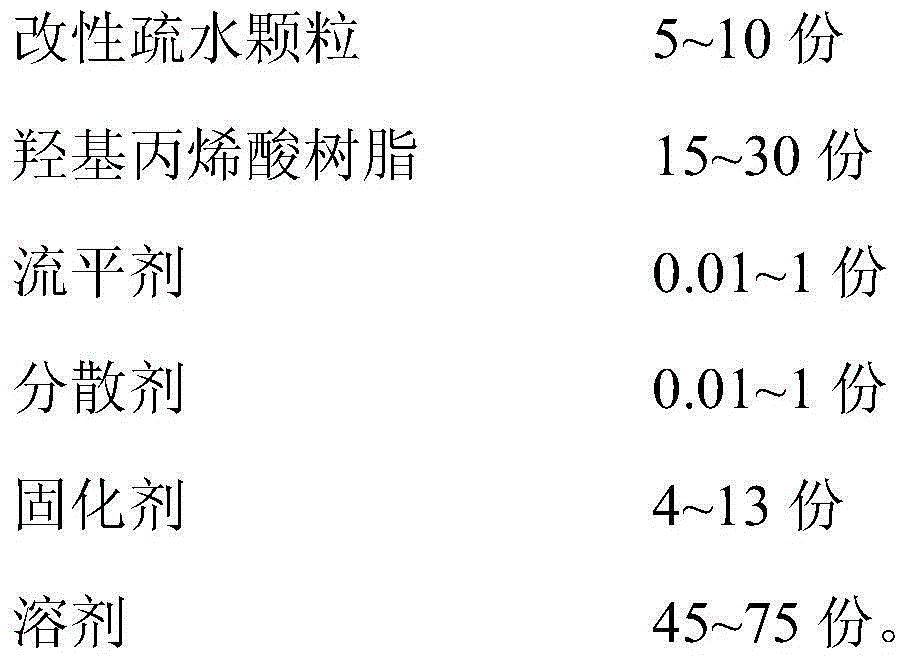

Method used

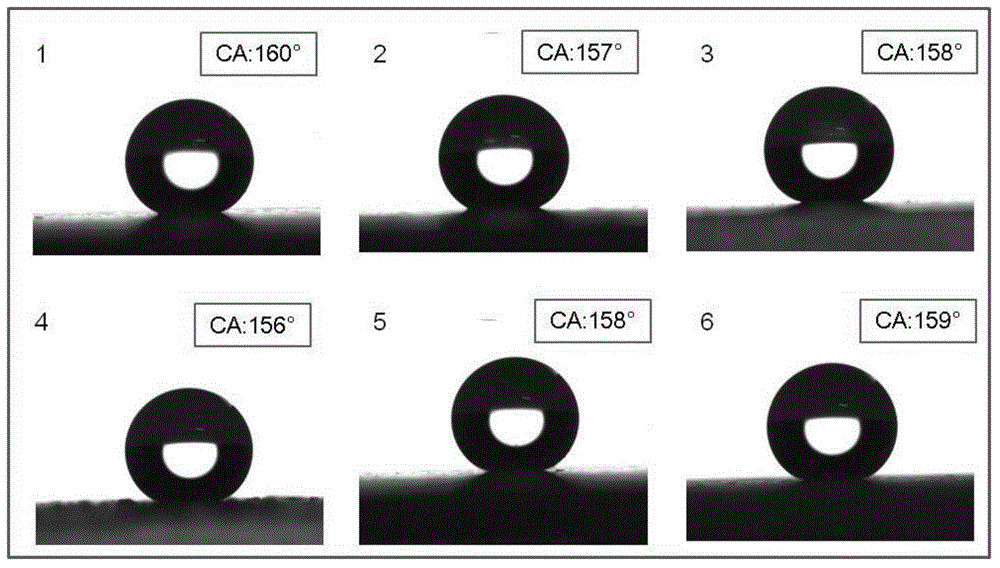

Image

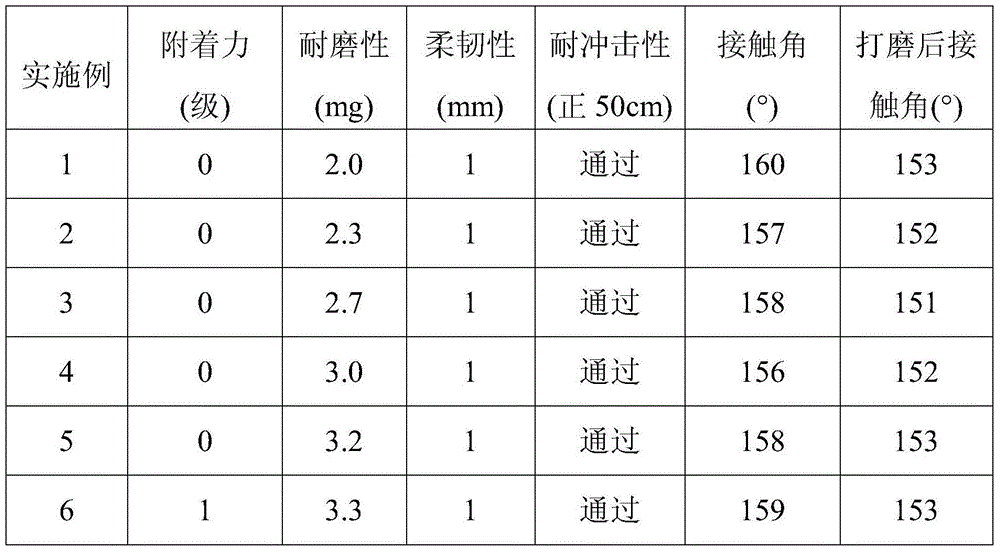

Examples

Embodiment 1

[0047] At room temperature to 30°C, add 10 parts of silica particles with a particle size of 50-100nm and 0.5 parts of vinyltriethoxy to the alkaline medium (pH=9) containing 45 parts of ethanol and 20 parts of ammonia water Silane, reacted for 0.5h under the action of ultrasonic waves, obtained modified hydrophobic particles after suction filtration and drying;

[0048] Dilute 15 parts of acrylic resin (solid content 70%) in 45 parts of organic solvent, then add 0.1 part of BYK-163#, 0.1 part of BYK-300# and 6 parts of modified hydrophobic particles, and mix the modified The hydrophobic particles are mixed evenly with the resin system (referred to as component A);

[0049] According to the molar ratio of the isocyanate in the curing agent to the hydroxyl group in the base resin of 1.05:1, mix the HDI trimer with the A-component paint, dilute it to a solid content for spraying, spray it on the substrate, and cure it at room temperature for 8 hours. Superhydrophobic acrylic po...

Embodiment 2

[0051] At room temperature to 30°C, add 12 parts of gamma-alumina particles with a particle size of 100-500nm and 1.2 parts of ten Heptafluorodecyltriethoxysilane was reacted for 1 hour under the action of ultrasonic waves, and modified hydrophobic particles were obtained after suction filtration and drying;

[0052] Dilute 27 parts of hydroxyacrylic resin (solid content 75%) in 63 parts of organic solvent, then add 0.3 part of Deqian 433#, 0.5 part of BYK-300# and 8 parts of modified hydrophobic particles, and mix the modified Hydrophobic particles are mixed evenly with the resin system (marked as component A);

[0053] Mix HDI biuret with component A paint according to the molar ratio of isocyanate in the curing agent to hydroxyl in the matrix resin of 1.05:1, dilute to a solid content for spraying, spray on the substrate, and cure at room temperature for 12 hours to obtain Superhydrophobic acrylic polyurethane coating.

Embodiment 3

[0055] At room temperature to 30°C, add 13 parts of rutile titanium dioxide with a particle size of about 100-300nm and 2.4 parts of tridecafluorooctyl triethyl Oxysilane, reacted for 1.5h under the action of ultrasonic waves, obtained modified hydrophobic particles after suction filtration and drying;

[0056] Dilute 30 parts of polyester-modified hydroxyl acrylic resin (solid content 80%) in 75 parts of organic solvent, then add 1.0 parts of BYK-163#, 0.9 parts of BYK-3700# and 10 parts of modified hydrophobic particles, Mix the modified hydrophobic particles with the resin system evenly through a high-speed mixer (marked as component A);

[0057] According to the molar ratio of the isocyanate in the curing agent to the hydroxyl group in the base resin of 1.1:1, mix the IPDI trimer with the A-component paint, dilute to the solid content of the spray, spray it on the substrate, and cure it at 80°C for 30 minutes. Obtain a superhydrophobic acrylic polyurethane coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com