Environment-friendly polyurethane adhesive, and preparation method and applications thereof

A polyurethane adhesive, an environmentally friendly technology, applied in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problem of physical properties that cannot meet high-strength standards, poor product stability, and poor yellowing resistance. Problems, achieve the effect of improving poor yellowing resistance, improving heat resistance, and good physical properties

Active Publication Date: 2017-05-10

ZHEJIANG HUAFON SYNTHETIC RESIN

View PDF5 Cites 36 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

This patented technology allows for improved quality adhesion with reduced yellowing caused by traditional methods like solvents or plasma treatment on glue products that are used widely throughout industry today due to their environmental friendliness and easy disposal compared to other types of bondings such as silicone rubber cements (SCA). Additionally, this innovation improves upon current techniques through introducing special chemical groups called phthalein-1, an esters made from sugar alcohols found naturally within plants' seeds. These modifications make certain polymers stronger but also have less volatile components than usual materials making them easier to break down into smaller parts when discarded after usage. Overall these improvements enhance durability over older technologies without compromising its effectiveness at preventing deteriorating yellowing.

Problems solved by technology

Technological Problem: Current methods for producing both types of polyisocyante adhesion agents involve emitting harmful chemicals into our atmosphere during manufacturing processes. Additionally, current methods require expensive raw material and use excess amounts of energy, leading to increased costs while also requiring significant resource consumption. Therefore there needs an improved process called Solvac® technology that can produce these products without relying on fossil fuel inputs like PU resin.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

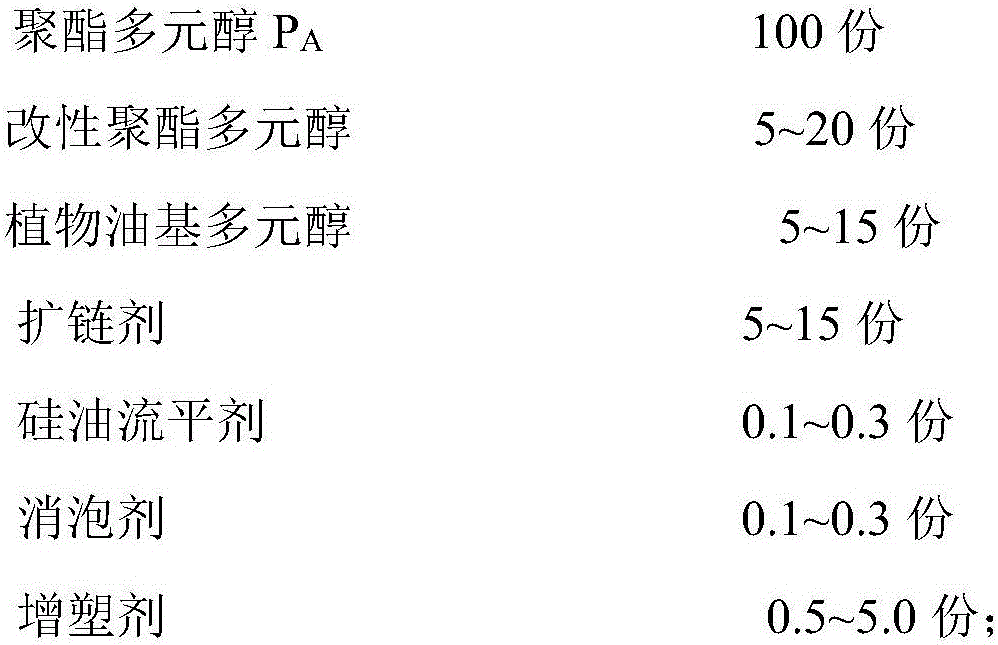

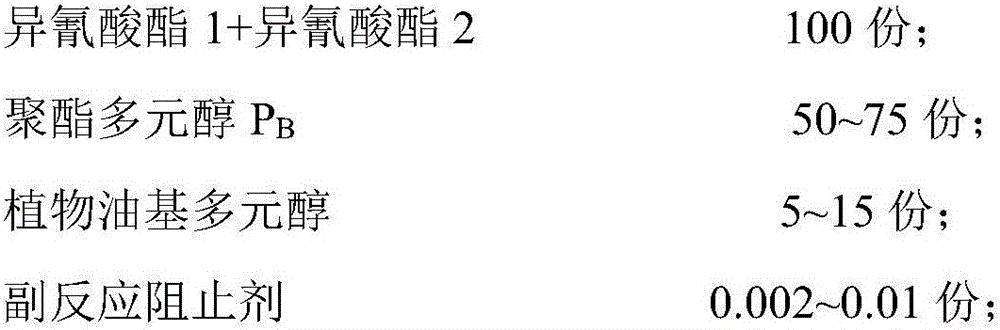

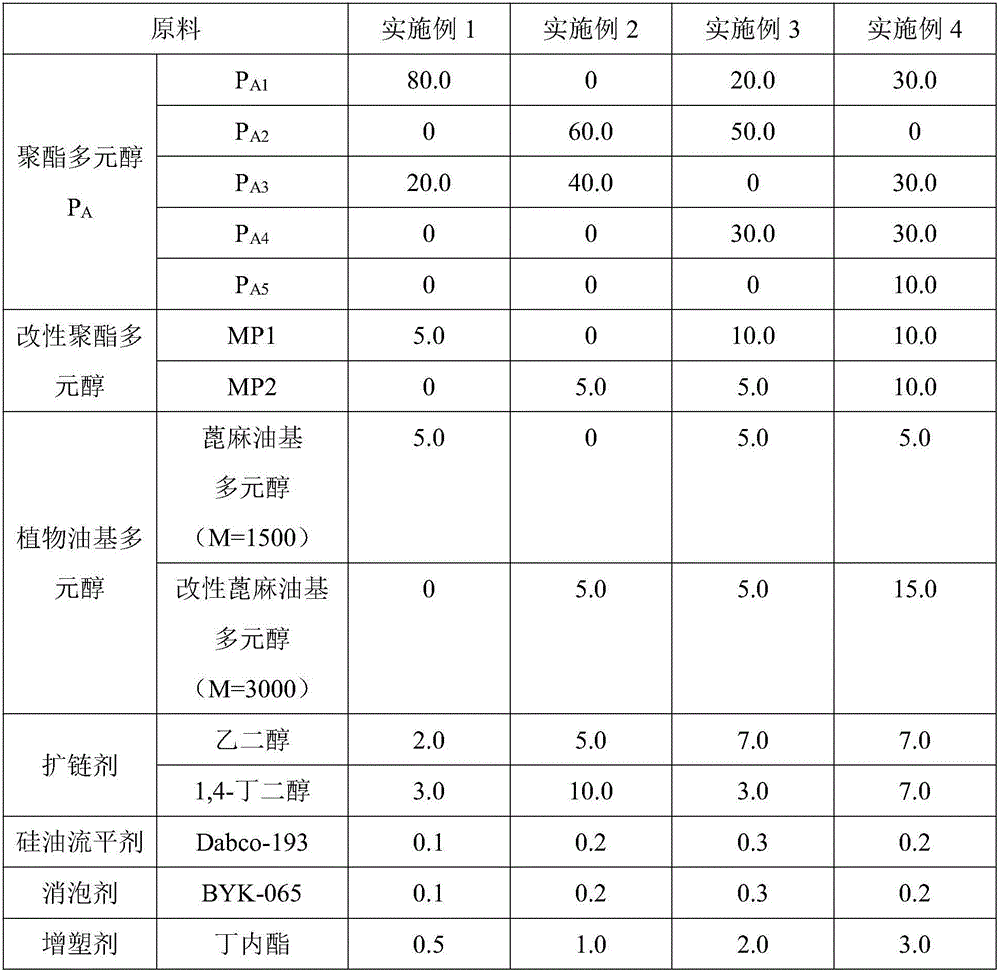

The invention discloses an environment-friendly polyurethane adhesive, and a preparation method and applications thereof. The environment-friendly polyurethane adhesive comprises a polyurethane resin A component, a polyurethane resin B component, and a catalyst. The polyurethane resin B component comprises isocyanate 1 and isocyanate 2, wherein the isocyanate 1 is isophorone diisocyanate, and the isocyanate 2 is one or more of m-xylidenediisocyanate (XDI), hexamethylene diisocyanate (HDI) trimer, and 1,5-naphthalene diisocyanate (NDI). The catalyst is a mixture of a delaying catalyst and a low temperature thermal sensitive catalyst. The problem of bad yellowing resistant performance of conventional adhesives is prominently improved. The heatproof property, flexibility, and hydrolysis resistant performance of finished products of adhesive are all enhanced. Moreover, the provided adhesive is environment-friendly and degradable, and can be easily recovered and utilized. The resources are saved, the operability of the adhesive is improved, and the curing time of the adhesive is shortened.

Description

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Owner ZHEJIANG HUAFON SYNTHETIC RESIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com