Aqueous polyurethane dispersoid for coating yellowing-resistant leather and preparation method thereof

A water-based polyurethane and dispersion technology, applied in polyurea/polyurethane coatings, leather surface treatment, small raw leather/big raw leather/leather/fur treatment, etc., can solve problems that cannot be solved fundamentally, and achieve low energy consumption , The effect of the simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

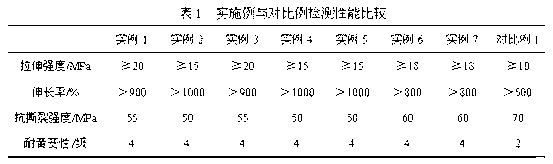

Examples

Embodiment 1

[0026] Add 60g of PPG and 20g of PTMEG into a 500mL four-necked flask, heat and melt, and vacuumize at 120°C for 1.5h. After vacuum stop, add 1g TMP, cool down to 60°C, add 15g HMDI and 20g IPDI, react for 1.5h, then add 5g dimethylol propionic acid, react for 0.5h, add 2g 1,4-butanediol, react for 2h. Neutralize with 2.5 g of triethylamine for 30 minutes, add 10 g of acetone to reduce the viscosity of the material, add 260 g of deionized water, and remove the solvent acetone by vacuuming to obtain a water-based polyurethane dispersion for leather finishing.

Embodiment 2

[0028] Add 55g of PPG and 20g of PTMEG into a 500mL four-necked flask, heat and melt, and vacuumize at 120°C for 1.5h. After stopping the vacuum, add 4g of castor oil, cool down to 60°C, add 28g of HMDI and 7g of IPDI, react for 1.5h, then add 8g of dimethylol butyric acid, react for 1h, add 1g of diethylene glycol, react for 2.5h. Neutralize with 5g of triethylamine for 30 minutes, add 10g of acetone to reduce the viscosity of the material, add 270g of deionized water, and remove the solvent acetone by vacuuming to obtain a water-based polyurethane dispersion for leather finishing.

Embodiment 3

[0030] Add 50g of PPG, 20g of PTMEG and 5g of PPA into a 500mL four-necked flask, heat and melt, and vacuumize at 120°C for 1.5h. After stopping the vacuum, add 1.5g TMP, cool down to 50°C, add 13.5g HMDI and 23g IPDI, react for 1.5h, then add 7g dimethylol propionic acid, react for 0.5h, add 0.5g triethylene glycol, react 2h. Neutralize with 4.5 g of triethylamine for 30 minutes, add 10 g of acetone to reduce the viscosity of the material, add 250 g of deionized water, and vacuumize to remove the solvent acetone to obtain a water-based polyurethane dispersion for leather finishing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com