Aqueous polyurethane dispersion with high solid content and low activation temperature, preparation method and application thereof

A water-based polyurethane, solid content technology, used in polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve the problems of resource waste, unusable, low activation temperature water-based polyurethane adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

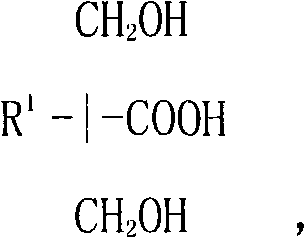

Method used

Image

Examples

Embodiment 1

[0074] In a glass reactor equipped with stirrer, condenser tube, thermocouple thermometer and calcium chloride drying tube, 145.2 grams of polyester diol (prepared by 1,4-butanediol and adipic acid, molecular weight 2000), 145.2 Gram poly(ester monoether) glycol (prepared by diethylene glycol and adipic acid, molecular weight 2000), 17.7 grams of DMPA and 2.0 grams of 1,4-butanediol reacted with 57.7 grams of IPDI and 16.9 grams of HDI at 70°C for 2 Hour. Then add 13.4 grams of triethylamine in the generated prepolymer and react for 15 minutes. The neutralized prepolymer was dispersed in 390 grams of deionized water at 70°C under rapid stirring. This dispersion continued to stir for 2 hours to obtain a stable translucent aqueous polyurethane dispersion with the following properties:

[0075] Solid content (%): 50.1

[0076] pH: 7.5

[0077] Viscosity (centipoise): 550

[0078] Activated at 50°C, can bond PVC / PVC, PP / PP and PET / PET

Embodiment 2

[0080]In the same glass reactor in Example 1, 127.4 gram polyester diols (prepared by 1,4-butanediol and adipic acid, molecular weight 2000), 193.1 gram poly(ester monoether) diols (made by diethyl ether) Diol and adipic acid preparation, molecular weight 2000) and 19.4 grams of DMPA were reacted with 75.0 grams of IPDI and 22.4 grams of HDI at 80° C. for 2 hours. Then add 14.7 grams of triethylamine and react for 15 minutes. The resulting neutralized isocyanate-terminated prepolymer was dispersed in 430.0 grams of deionized water at 60°C with rapid agitation, followed by the slow addition of a solution of 5.5 grams of ethylenediamine and 2.5 grams of ethanolamine in 30 grams of water. This dispersion continued to stir for 2 hours to obtain a stable translucent aqueous polyurethane dispersion with the following properties:

[0081] Solid content (%): 49.8

[0082] pH: 7.3

[0083] Viscosity (centipoise): 450

[0084] Activation at 50°C can bond PVC / PVC, PP / PP and PET / PET ...

Embodiment 3

[0086] In the same glass reactor in Example 1, 135.1 grams of polyester diol (prepared from 1,4-butanediol and adipic acid, molecular weight 2000), 55.0 grams of poly(ester monoether) glycol (made from diethylene Preparation of diol and adipic acid, molecular weight 2000) and 100.3 grams of polyoxypropylene diol (molecular weight 2000), 17.7 grams of DMPA and 2.0 grams of 1,4-butanediol reacted with 57.7 grams of IPDI and 16.9 grams of HDI at 70 ° C for 2 hours . Then add 13.4 grams of triethylamine and react for 15 minutes. The prepolymer was dispersed in 390 grams of deionized water at 70°C under rapid stirring. This dispersion continued to stir for 2 hours to obtain a stable translucent aqueous polyurethane dispersion with the following properties:

[0087] Solid content (%): 50.2

[0088] pH: 7.4

[0089] Viscosity (centipoise): 480

[0090] Activation at 50°C can bond PVC / PVC, PP / PP and PET / PET

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com