Adhesive composition for optical films, adhesive optical film and image display

A technology for optical films and adhesives, applied in the direction of film/sheet adhesives, adhesive types, ester copolymer adhesives, etc., which can solve the problems of insufficient reworkability and workability. , to achieve the effect of inhibiting shedding or contamination, improving reworkability, and improving machinability and reworkability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

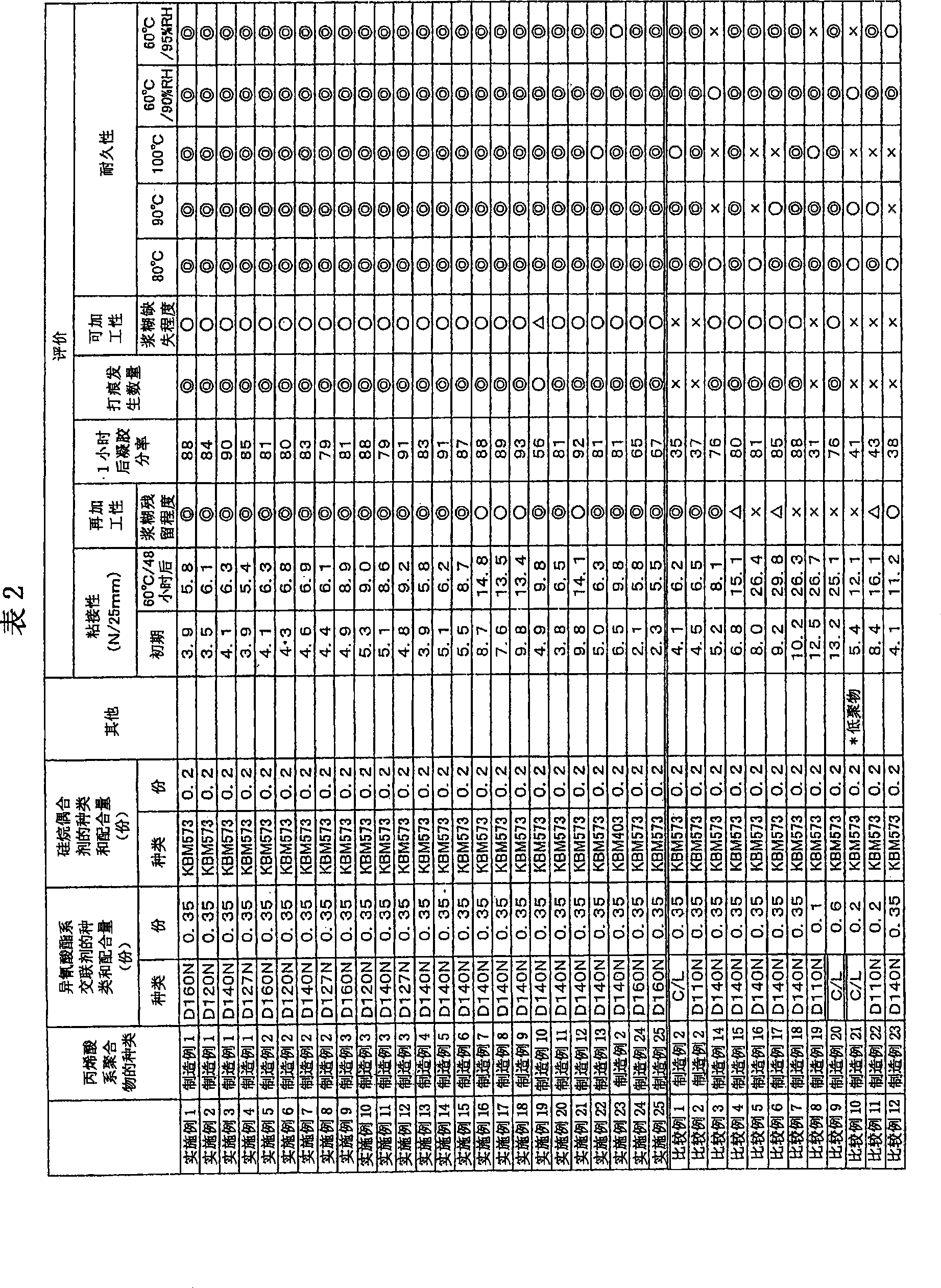

[0156] Hereinafter, although an Example demonstrates this invention concretely, this invention is not limited to these Examples. However, the parts and % in each example are based on weight. Evaluation items in Examples and the like were measured as follows.

[0157]

[0158] The weight average molecular weight of the obtained (meth)acrylic polymer was measured by GPC (gel permeation chromatography). As the sample, a sample was dissolved in dimethylformamide to obtain a 0.1% by weight solution, which was allowed to stand overnight, and then filtered through a 0.45 μm membrane filter.

[0159] ·Analyzing device: Tosoh-manufactured by HLC-8120GPC

[0160] ·Column: Tosoh—manufactured by the company, SuperAWM—H, AW4000, AW2500

[0161] ·Column size: each 6.0mmΦ×150mm

[0162] Eluent: 30mM-lithium bromide, 30mM-phosphoric acid in dimethylformamide

[0163] ·Flow rate: 0.4ml / min

[0164] Detector: Differential Refractometer (RI)

[0165] ·Column temperature: 40℃

[0166] ·...

manufacture example 1

[0170]

[0171]Put 99.1 parts of butyl acrylate, 0.1 part of N,N-dimethylaminoethyl acrylate, 0.3 parts of acrylic acid, and 4-hydroxybutyl acrylate into a four-necked flask equipped with a stirring paddle, a thermometer, a nitrogen inlet tube, and a cooler. 0.5 parts of ester, 0.1 part of 2,2'-azobisisobutyronitrile as a polymerization initiator, and 200 parts of ethyl acetate were slowly stirred while nitrogen gas was introduced, and after nitrogen substitution, the liquid temperature in the flask was maintained to The polymerization reaction was carried out at around 60° C. for 6 hours to prepare an acrylic polymer solution. The weight average molecular weight of the acrylic polymer is 2.05 million.

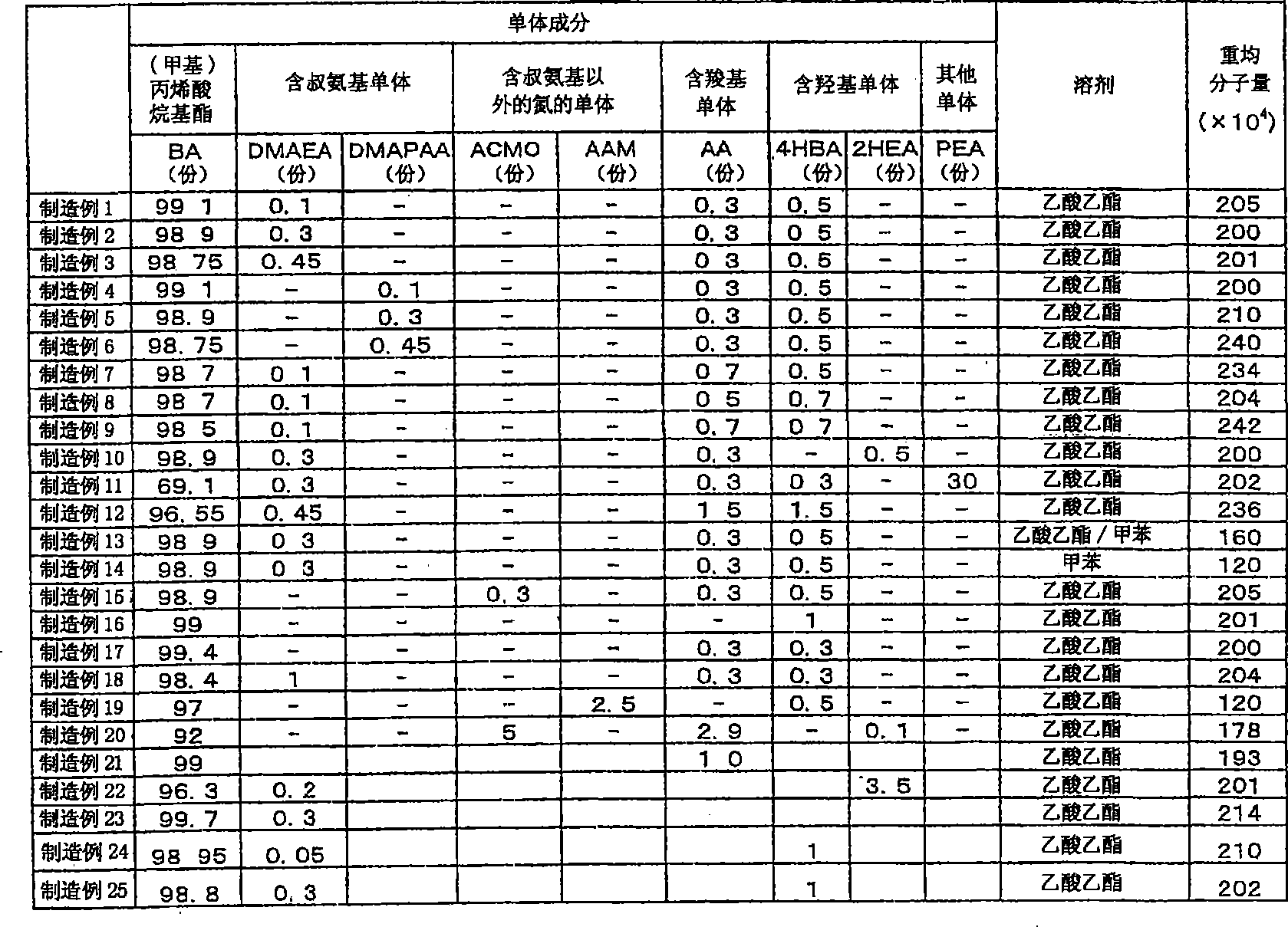

manufacture example 2~25

[0173] In Production Example 1, an acrylic polymer solution was prepared in the same manner as in Production Example 1, except that at least one of the types and amounts of monomer components used and the solvent were changed as shown in Table 1. Table 1 shows the weight average molecular weight of the acrylic polymer obtained in each example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| gel fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com