Low-temperature-resistant and ageing-resistant modified fluororubber cable sheath material

A technology of modifying fluororubber and cable sheath, which is applied in the direction of insulated cables, rubber insulators, cables, etc., can solve the problem that the aging resistance and low temperature resistance cannot meet the requirements of the society, the low temperature resistance of fluororubber is poor, and the use performance is lost. and other problems, to achieve the effect of improving tear resistance, good aging resistance and reducing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

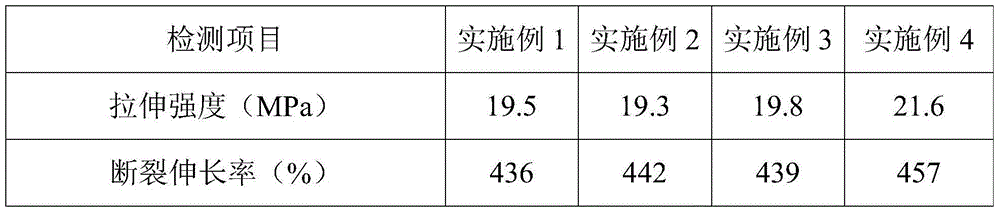

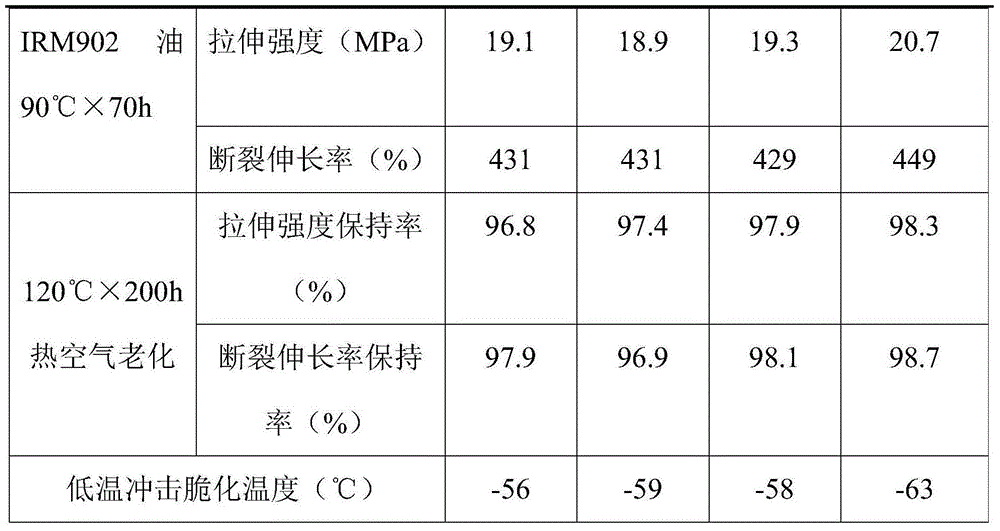

Examples

Embodiment 1

[0020] The low temperature and aging resistant modified fluororubber cable sheath material of the present invention, its raw material comprises by weight: 60 parts of fluororubber, 25 parts of butadiene rubber, 15 parts of ethylene-vinyl acetate copolymer, 3 parts of rare earth complex, 25 parts of white carbon black, 10 parts of modified carbon nanotubes, 30 parts of nano-kaolin, 0 parts of castor oil, 6 parts of rapeseed oil, 1.8 parts of stearic acid, 0.5 parts of zinc oxide, 3 parts of sulfur, diisopropyl peroxide 0.5 parts of benzene, 0.5 parts of triallyl isocyanurate, 1 part of dioctyl adipate, 2 parts of epoxidized triglycerides, 0.5 parts of phytic acid ester, 3 parts of silane coupling agent, 0.5 parts of accelerator M, 1.8 parts of accelerator DM, 0 parts of anti-aging agent RD, and 1.5 parts of anti-aging agent 4010NA.

Embodiment 2

[0022] The low temperature and aging resistant modified fluororubber cable sheath material of the present invention, its raw material comprises by weight: 85 parts of fluororubber, 10 parts of butadiene rubber, 5 parts of ethylene-vinyl acetate copolymer, 5 parts of rare earth complex, 10 parts of white carbon black, 30 parts of modified carbon nanotubes, 10 parts of nano-kaolin, 5 parts of castor oil, 2 parts of rapeseed oil, 3.5 parts of stearic acid, 1.3 parts of zinc oxide, 1.5 parts of sulfur, diisopropyl peroxide 2 parts of benzene, 0.3 parts of triallyl isocyanurate, 2 parts of dioctyl adipate, 1 part of epoxidized triglyceride, 1.5 parts of phytic acid ester, 1 part of silane coupling agent, 1 part of accelerator M, 0.5 part of accelerator DM, 1.5 parts of anti-aging agent RD, 0.5 part of anti-aging agent 4010NA;

[0023] Wherein, the rare earth complex is prepared according to the following process: 10 parts by weight of terephthalic acid and 35 parts of rare earth ni...

Embodiment 3

[0025] The low temperature and aging resistant modified fluorine rubber cable sheath material of the present invention, its raw material comprises by weight: 72 parts of fluorine rubber, 16 parts of butadiene rubber, 12 parts of ethylene-vinyl acetate copolymer, 4.6 parts of rare earth complex, 13.4 parts of white carbon black, 15 parts of modified carbon nanotubes, 21 parts of nano kaolin, 3.6 parts of castor oil, 5.3 parts of rapeseed oil, 2.2 parts of stearic acid, 1.1 parts of zinc oxide, 1.9 parts of sulfur, diisopropyl peroxide 1.6 parts of benzene, 0.48 parts of triallyl isocyanurate, 1.4 parts of dioctyl adipate, 1.8 parts of epoxidized triglyceride, 1.4 parts of phytic acid ester, 2.5 parts of silane coupling agent, 0.67 parts of accelerator M, 1.6 parts of accelerator DM, 1.1 parts of anti-aging agent RD, 1.3 parts of anti-aging agent 4010NA;

[0026] Wherein, the rare earth complex is prepared according to the following process: 20 parts by weight of terephthalic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com