Polyvinyl chloride geomembrane modified by nitrile-butadiene rubber

A technology of nitrile rubber and polyvinyl chloride, applied in marine engineering, water conservancy engineering, construction and other directions, can solve the problems of increasing the reinvestment cost of enterprises, affecting the use effect of geomembrane, excessive stretching of geomembrane, etc., saving money, Superior sealing performance and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

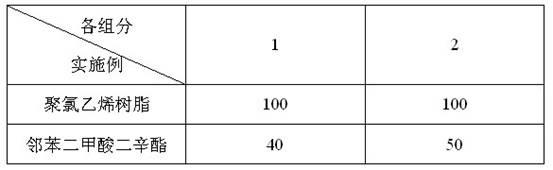

[0029] Toughened, reinforced and good sealing polyvinyl chloride geomembrane modified by nitrile rubber, the proportion of each component of the preparation is: (A) 100 parts by weight of polyvinyl chloride resin; (B) dioctyl phthalate 40PHR ; (C) dioctyl adipate 5PHR; (D) epoxidized soybean oil 6PHR; (E) heat stabilizer 2.8PHR; (F) nitrile rubber 5PHR; (G) calcium carbonate 15PHR; (H) stearin Acid 0.2PHR; (I) white carbon black 2PHR; (J) talcum powder 6PHR; (K) appropriate amount of pigment. Wherein heat stabilizer selects liquid stabilizer and metal soap stabilizer for use in combination, and metal soap stabilizer selects barium stearate and zinc stearate for use in combination.

Embodiment 2

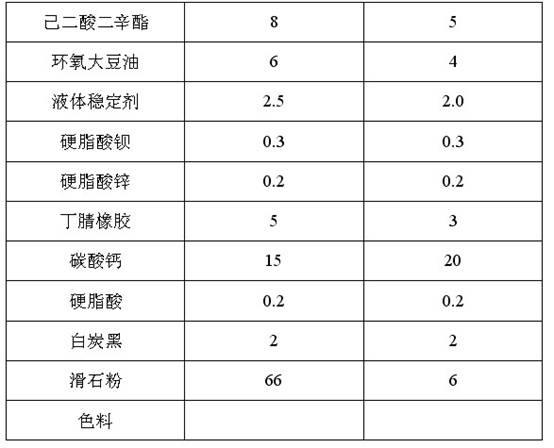

[0031] Toughened, reinforced and good sealing polyvinyl chloride geomembrane modified by nitrile rubber, the proportion of each component of the preparation is: (A) polyvinyl chloride resin 100 parts by weight; (B) dioctyl phthalate 50PHR ; (C) dioctyl adipate 8PHR; (D) epoxidized soybean oil 4PHR; (E) heat stabilizer 2.5PHR; (F) nitrile rubber 3PHR; (G) calcium carbonate 20PHR; (H) stearin Acid 0.2PHR; (I) white carbon black 2PHR; (J) talcum powder 6PHR; (K) appropriate amount of pigment. Wherein the heat stabilizer is used in combination with a liquid stabilizer and a metal soap stabilizer, and the metal soap stabilizer is used in combination with barium stearate and zinc stearate.

[0032] The above components refer to the table below.

[0033] After weighing the components in 1 in Table 1, stir with a high-speed mixer for 270s, discharge at about 92°C, and then internally knead with a 10,000-horsepower machine, then fully knead in two open plastic mixers, and extrude Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com