Insulation electrical engineering bushing plastic and preparation method thereof

A technology of electrical bushings and plastics, applied in the direction of insulated cables, insulated conductors, organic insulators, etc., can solve the problems of low insulation performance, flame retardancy and impact resistance of plastic bushings, and achieve high strength, high impact resistance and toughness , good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

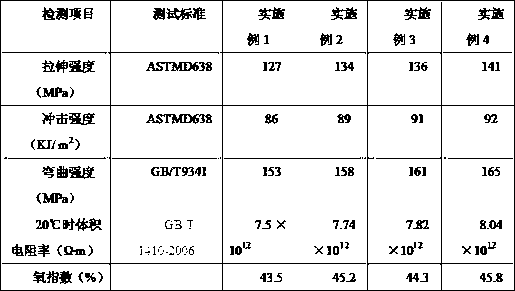

Examples

Embodiment 1

[0038] This embodiment provides a plastic for insulating electrical bushings, which contains the following components in parts by mass:

[0039] PVC resin 70 parts

[0040] Acrylonitrile-butadiene-styrene copolymer 10 parts

[0041] Dioctyl phthalate 30 parts

[0042] Dioctyl adipate 3 parts

[0043] Epoxidized soybean oil 0.5 parts

[0044] Calcined kaolin 1 part

[0045] Dibasic lead phosphite 1.5 parts

[0046] Fatty acid ester 1.2 parts

[0047] Aluminum hydroxide 5 parts

[0048] Zinc borate 2 parts

[0049] Barium stearate 1.5 parts

[0050] Organotin stabilizer 1 part

[0051] PE wax 1.5 parts.

[0052] The preparation steps of plastics for insulating electrical bushings are as follows:

[0053] Step 1: Stir PVC resin, dioctyl adipate and epoxidized soybean oil evenly in a high-speed mixer, then add acrylonitrile-butadiene-styrene copolymer, dioctyl phthalate, Calcined kaolin, dibasic lead phosphite, fatty acid ester, aluminum hydroxide, zinc borate, barium ...

Embodiment 2

[0056] This embodiment provides a plastic for insulating electrical bushings, which contains the following components in parts by mass:

[0057] PVC resin 75 parts

[0058] Acrylonitrile-butadiene-styrene copolymer 13 parts

[0059] Dioctyl phthalate 35 parts

[0060] Dioctyl adipate 4 parts

[0061] Epoxidized soybean oil 1.3 parts

[0062] Calcined kaolin 2 parts

[0063] Dibasic lead phosphite 1.9 parts

[0064] Fatty acid ester 1.3 parts

[0065] Aluminum hydroxide 6 parts

[0066] 3 parts zinc borate

[0067] Barium stearate 2 parts

[0068] Organotin stabilizer 2 parts

[0069] PE wax 2 parts.

[0070] The preparation steps of plastics for insulating electrical bushings are as follows:

[0071] Step 1: Stir PVC resin, dioctyl adipate and epoxidized soybean oil evenly in a high-speed mixer, then add acrylonitrile-butadiene-styrene copolymer, dioctyl phthalate, Calcined kaolin, dibasic lead phosphite, fatty acid ester, aluminum hydroxide, zinc borate, barium st...

Embodiment 3

[0074] This embodiment provides a plastic for insulating electrical bushings, which contains the following components in parts by mass:

[0075] PVC resin 85 parts

[0076] Acrylonitrile-butadiene-styrene copolymer 16 parts

[0077] Dioctyl phthalate 42 parts

[0078] Dioctyl adipate 7 parts

[0079] Epoxidized soybean oil 2.5 parts

[0080] Calcined kaolin 4 parts

[0081] 2.5 parts of dibasic lead phosphite

[0082] Fatty acid ester 1.6 parts

[0083] Aluminum hydroxide 8.5 parts

[0084] 4 parts zinc borate

[0085] Barium stearate 2.5 parts

[0086] Organotin stabilizer 3.2 parts

[0087] 3.1 parts of PE wax.

[0088] The preparation steps of plastics for insulating electrical bushings are as follows:

[0089] Step 1: Stir PVC resin, dioctyl adipate and epoxidized soybean oil evenly in a high-speed mixer, then add acrylonitrile-butadiene-styrene copolymer, dioctyl phthalate, Calcined kaolin, dibasic lead phosphite, fatty acid ester, aluminum hydroxide, zinc bor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com