Formula of nitrile rubber pad for sealing transformer oil

A technology of nitrile rubber and transformer oil, applied in chemical instruments and methods, and other chemical processes, can solve problems such as surface cracks, loss of sealing performance, and transformer oil leakage, so as to improve aging resistance, prolong service life, The effect of solving the leakage problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

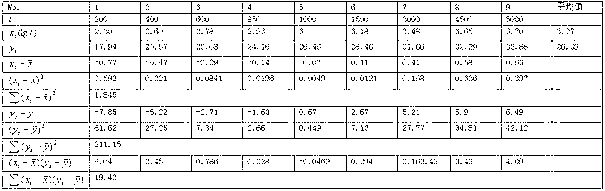

[0013] In the implementation of the present invention, the numerical ratio of each component is as follows: weight percentage sees the following table

[0014] component name Example 1 Example 2 Example 3 Example 4 Nitrile rubber 3365 100 100 100 100 Carbon black N330 65 66 67 68 Dioctyl adipate DOA 5 7 12 17 Zinc oxide 10 11 12 13 stearic acid 1.0 1.2 1.4 1.5 Antiaging agent RD 1.0 1.5 1.8 2.0 Antiager MB 1.0 1.2 1.5 2.0 Vulcanizing agent DCP 3.0 4.0 4.0 5.0 Vulcanization aid TAIC 2.0 3.0 4.0 4.0

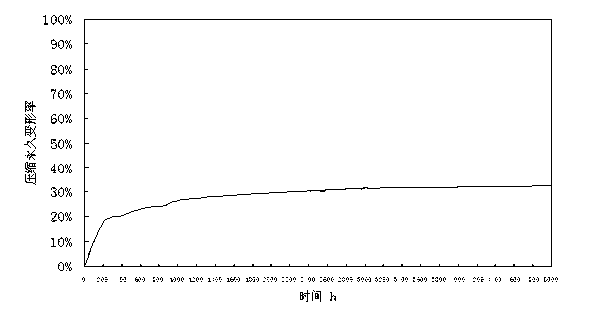

[0015] In order to verify the service life of the product of the present invention, the use environment and working state of the simulated gasket were carried out, and the compression set test was continuously done for 5000 hours. Open the experimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com