Preparation method of ultrahigh-sulfonic-acid-density biomass carbon solid acid

A technology of biomass carbon and ultra-high sulfonic acid, which is applied in the preparation of organic compounds, carboxylic acid ester preparation, chemical instruments and methods, etc., and can solve the problems of limited solid acid catalytic performance, low yield, and low content of sulfonic acid groups, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

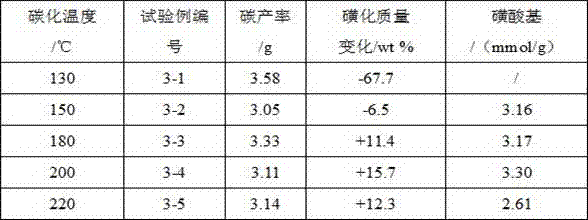

[0017] This example is used to illustrate the method for preparing ultra-high sulfonic acid density biomass carbon solid acid by using bamboo powder and the obtained ultra-high sulfonic acid density biomass carbon solid acid.

[0018] (1) Pretreatment: Weigh 6 g of bamboo powder into the lining of a 100 mL crystallization kettle, weigh 3.6 g of ferric chloride and dissolve it in 20 mL of deionized water, add 4 drops of concentrated hydrochloric acid to prevent hydrolysis, add 1.2 g of phenol, Stir with a glass rod to make it evenly mixed, then seal the crystallization kettle and put it in an oven at 60°C for 12 hours;

[0019] (2) Hydrothermal carbonization: In an oven, the crystallization kettle was heated to 150°C, and the reaction time was 9 h. After the reaction, cool down to room temperature naturally, take out the inner lining, wash it twice with deionized water, once with dilute hydrochloric acid, and twice with deionized water, dry the obtained biomass carbon solid at ...

Embodiment 2

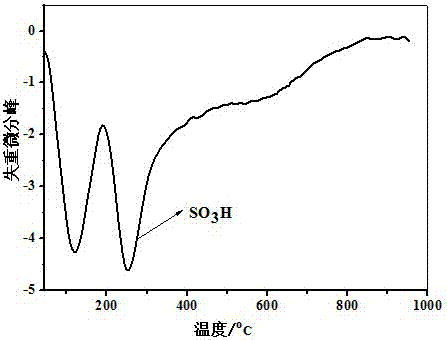

[0032] This example is used to illustrate the use of 180 ° C carbonization temperature for the preparation of HBC-SO 3 The impact of H-II.

[0033] (1) Pretreatment: Weigh 6 g of bamboo powder into the lining of a 100 mL crystallization kettle, weigh 3.6 g of ferric chloride and dissolve it in 20 mL of deionized water, add 4 drops of concentrated hydrochloric acid to prevent hydrolysis, add 1.2 g of phenol, Stir with a glass rod to make it evenly mixed, then seal the crystallization kettle and put it in an oven at 60°C for 12 hours;

[0034] (2) Hydrothermal carbonization: In an oven, the crystallization was heated to 180 °C, and the reaction time was 9 h. After the reaction, it was cooled down to room temperature naturally, and the lining was taken out, washed twice with deionized water, once with dilute hydrochloric acid, and twice with deionized water, and dried to obtain 3.2 g of solid carbon material;

[0035] (3) Sulfonation: Take 2 g of the solid carbon material obtai...

Embodiment 3

[0056] This example is used to illustrate that while using ferric chloride, add other Lewis acid catalytic carbonization-sulfonated bamboo powder to prepare HBC-SO 3 H's method.

[0057] (1) Pretreatment: Weigh 6 g of bamboo powder into the lining of a 100 mL crystallization kettle, weigh 3.0 g of ferric chloride and 0.6 g of copper chloride and dissolve them in 20 mL of deionized water, add 4 drops of concentrated hydrochloric acid to prevent hydrolysis , add 1.2g of phenol, stir with a glass rod to make it evenly mixed, then seal the crystallization kettle, put it in a 60°C oven for 12h;

[0058] (2) Hydrothermal carbonization: In an oven, the crystallization was heated to 180 °C, and the reaction time was 9 h. After the reaction, cool down to room temperature naturally, take out the inner lining, wash it twice with deionized water, once with dilute hydrochloric acid, and twice with deionized water, and dry the obtained solid to obtain 3.2 g;

[0059] (3) Sulfonation: Take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com