Silver-carrying antibacterial hydrocolloid dressing and preparation method thereof

A hydrocolloid and silver-loaded technology, applied in medical science, absorbent pads, bandages, etc., can solve problems such as inability to use bactericides or adjuvants, limit the range of hydrocolloids to choose, reduce bactericidal activity, etc., to reduce biological safety risk, maintain the balance of skin flora, and increase the effect of antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

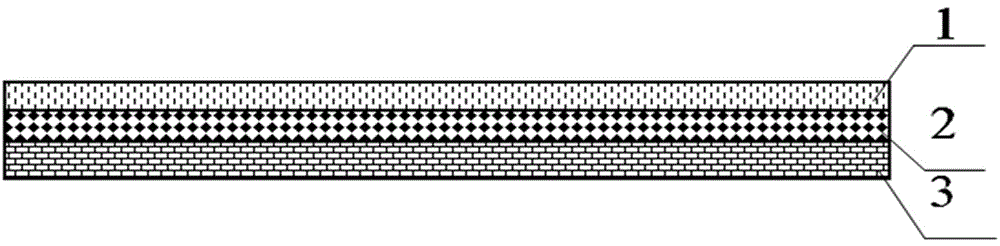

Embodiment 1

[0027] 1. Fully mix 20 parts of sodium carboxymethyl cellulose and 0.001 parts of silver-containing compound with superfine grinding and use it as component A; 2. Mix SIS thermoplastic elastomer (40 parts), 25 parts of liquid paraffin, viscosity increasing 5 parts of resin, 5 parts of antioxidant BHT, and 10 parts of plasticizer dioctyl adipate were sequentially added to the kneader at 150°C and 45 r / min, and mixed for 30 minutes, and the uniformly mixed material was used as component B; 1. Add component A into the kneader, stir at 120°C, 45r / min for 30min, and mix it evenly as component C; Add 3 parts of the material to component C, and stir for 10 minutes at 100°C and 45r / min; 5. Apply the uniformly mixed material on the isolation layer 3, and cover the polyurethane backing 1, and extinguish it by Co60 radiation. Bacteria can be made into finished products. When in use, the isolation layer 3 is removed, the hydrocolloid functional core 2 is pasted on the wound, and the back...

Embodiment 2

[0029] 1. Thoroughly mix 35 parts of sodium carboxymethyl cellulose and 0.5 parts of silver-containing compound with superfine grinding and use as component A; 2. Mix SIS thermoplastic elastomer (25 parts), 15 parts of liquid paraffin, viscosifying Add 10 parts of resin, 2.5 parts of antioxidant BHT, and 5 parts of plasticizer dioctyl adipate into the kneader in turn. Mix for 30 minutes under the conditions of 150 ° C and 45 r / min, and use the uniformly mixed material as component B. 3. Add component A to the kneader, stir for 30min at 120°C and 45r / min to make it evenly mixed as component C; Add 2.4 parts of skin extract to component C, and stir for 10 minutes at 100°C and 45r / min; 5. Apply the uniformly mixed material on the isolation layer 3, and cover the polyurethane backing 1, and pass through Co60 radiation According to sterilization, it can be made into a finished product. When in use, the isolation layer 3 is removed, the hydrocolloid functional core 2 is pasted on t...

Embodiment 3

[0031] 1. Superfinely mix 50 parts of sodium carboxymethyl cellulose and 5 parts of silver-containing compound and use it as component A; 2. Mix SIS thermoplastic elastomer (5 parts), 5 parts of liquid paraffin, Add 20 parts of resin, 0.01 part of antioxidant BHT, and 1 part of plasticizer dioctyl adipate into the kneader in turn. Mix for 30 minutes under the conditions of 150°C and 45 r / min, and use the uniformly mixed material as component B. 3. Add component A to the kneader, stir for 30 minutes at 120°C and 45r / min to make it evenly mixed as component C; Add 0.03 parts of skin extract to component C, and stir for 10 minutes at 100°C and 45r / min; 5. Apply the uniformly mixed material on the isolation layer 3, and cover the polyurethane backing 1, and pass through Co60 radiation According to sterilization, it can be made into a finished product. When in use, the isolation layer 3 is removed, the hydrocolloid functional core 2 is pasted on the wound, and the backing 1 is in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com