Floor, manufacture method and application thereof

A floor and red mud technology, applied in building structures, floors, buildings, etc., can solve the problems of volatile harmful gases, inconvenient use, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

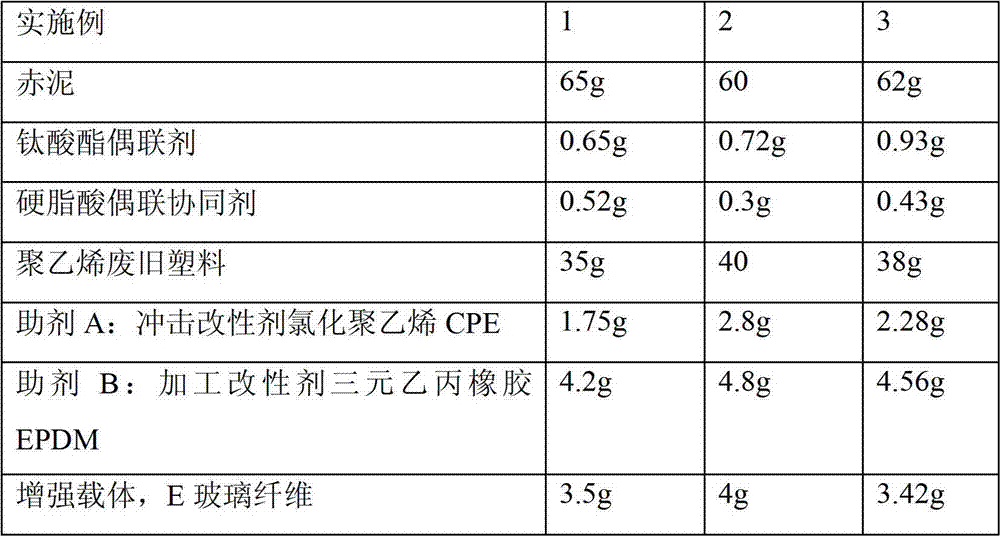

Embodiment 1

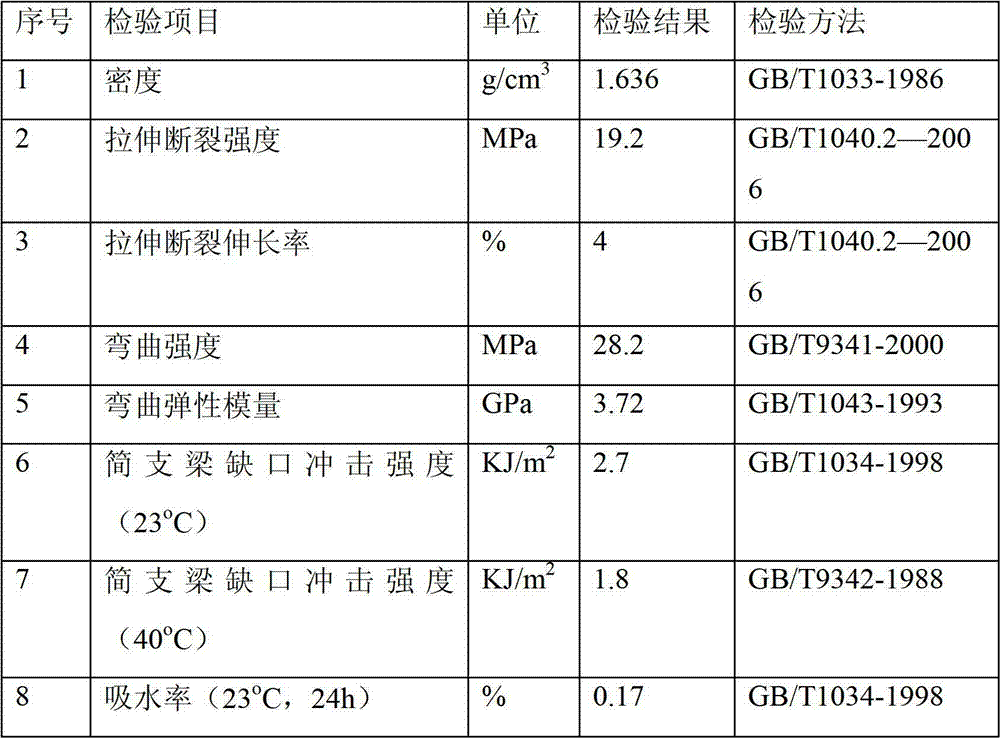

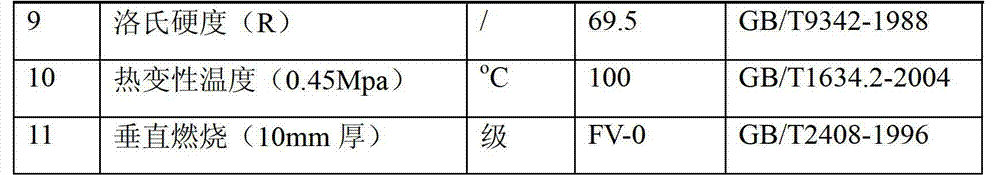

[0075] Embodiment 1. Preparation of Floor 1

[0076] Step 1. Activate red mud:

[0077] (1) Dry 65g of red mud in a rotary flash dryer to make the water content less than 0.3%, and the particle size is greater than or equal to 150 mesh powder,

[0078](2) Put the dried red mud into the DYHL300 / 600 mixing and kneading machine at a speed of 1000 rpm to generate heat by friction. When the temperature of the mixing machine rises to 100-110°C, remove the red mud The free moisture in the red mud should be controlled to be less than or equal to 0.3%, the general time is 2 to 5 minutes, and then add titanate coupling agent, the amount added is 1% to 1.2% of the red mud, 100 to 120°C In a mixer, surface activate the red mud and stir for 5-10 minutes. When the temperature drops to 50°C, add coupling synergist stearic acid in an amount of 0.5-0.8% of the amount of red mud, stir evenly at 48-52°C, and then discharge for use.

[0079] Step 2. Plastic and Additive Treatment:

[0080] Po...

Embodiment 2

[0097] Embodiment 2. step is the same as embodiment 1.

Embodiment 3

[0098] Embodiment 3. step is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com