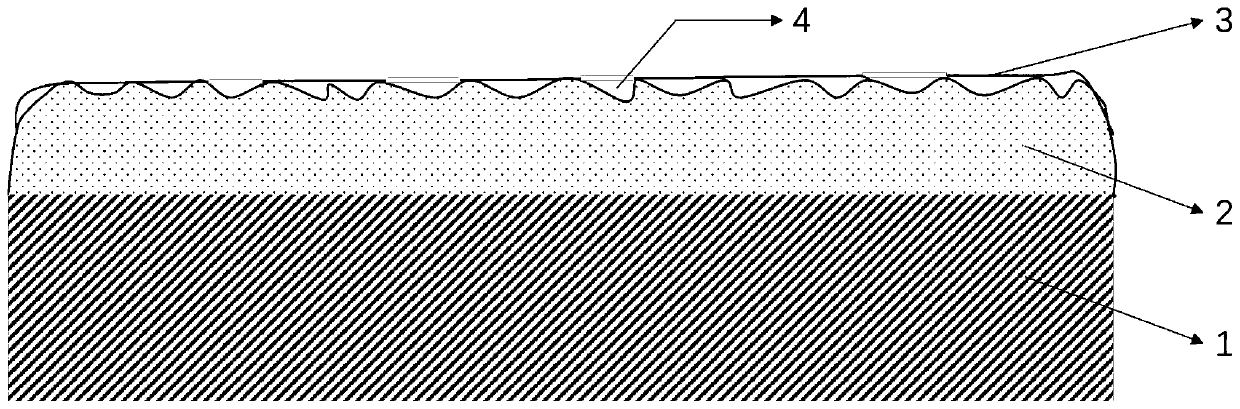

Antique ceramic exterior wall tile subjected to sand blasting treatment and preparation method thereof

A technology of sand blasting and ceramics, which is applied in the field of building ceramic materials, can solve the problems of insufficient strength and low density, and achieve the effects of low production cost, simple method and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

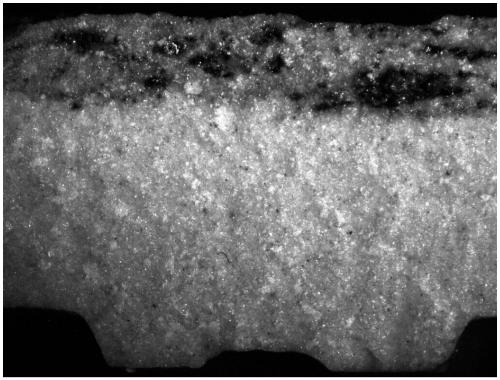

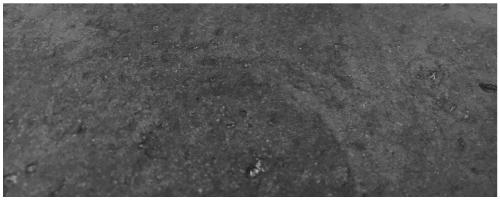

Image

Examples

Embodiment 1

[0046] A method for preparing sandblasting-treated antique ceramic exterior wall tiles, comprising the following steps:

[0047] 1) Mixing of raw materials: In terms of parts by mass, take 100 parts of the bottom blank and 2.5 parts of the coral red material, and pulverize them together in a powder machine for 30 minutes to obtain the red fabric base material. The chemical composition of 100 parts of the bottom blank is: 72 parts of silicon oxide, 17 parts of aluminum oxide, 1 part of iron oxide, 2 parts of calcium oxide, 4 parts of magnesium oxide, and 4 parts of sodium oxide;

[0048] 2) Take 10 parts of the imitation metal glaze powder and pulverize it in a powder mill for 30 minutes, then put it into a ball mill and mill it for 3 hours until the particle size is 0.45um to obtain fine particle imitation metal glaze powder. Take 70 parts of the bottom blank and pulverize it in a powder mill for 30 minutes, put it into a ball mill and mill it for 3 hours until the particle si...

Embodiment 2

[0067] A method for preparing an antique ceramic exterior wall tile treated by a sandblasting machine, comprising the following steps:

[0068] 1) Mixing of raw materials: In terms of parts by mass, take 80 parts of the bottom blank and 1.5 parts of the coral red material, and pulverize them together in a powder machine for 20 minutes to obtain the red fabric base material. The chemical composition of the bottom blank is: 73 parts of silicon oxide, 16 parts of aluminum oxide, 1.5 parts of iron oxide, 1.5 parts of calcium oxide, 3.5 parts of magnesium oxide, and 4.5 parts of sodium oxide;

[0069] 2) Take 5 parts of the imitation metal glaze powder and pulverize it in a powder machine for 20 minutes, then put it into a ball mill and mill it for 4 hours until the particle size is 0.2um to obtain fine particle imitation metal glaze powder. Take 65 parts of the bottom blank, pulverize it in a powder mill for 20 minutes, put it into a ball mill and mill it for 4 hours until the par...

Embodiment 3

[0082] A method for preparing an antique ceramic exterior wall tile treated by a sandblasting machine, comprising the following steps:

[0083] 1) Mixing of raw materials: In terms of parts by mass, take 100 parts of bottom blank, 0.1 part of cobalt blue, 2 parts of zirconium silicate, 0.1 part of manganese red, and 0.6 part of billet black, and pulverize them together in a powder machine for 40 minutes to obtain a gray fabric base material. The chemical composition of the bottom blank is: 74 parts of silicon oxide, 15 parts of aluminum oxide, 2 parts of iron oxide, 2 parts of calcium oxide, 3 parts of magnesium oxide, and 4 parts of sodium oxide;

[0084] 2) Take 5 parts of the imitation metal glaze powder and pulverize it in a powder mill for 40 minutes, then put it into a ball mill and mill it for 2 hours until the particle size is 1 um, and obtain fine particles of the imitation metal glaze powder. Take 65 parts of the bottom blank and pulverize it in a powder mill for 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com