Kaolinite archaized brick and method thereof

A technology of kaolinite and antique bricks, applied in the field of restoration of ancient buildings, can solve the problems of high density of unburned bricks, and achieve the effects of realistic antique effect, reducing density and avoiding cumbersome production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

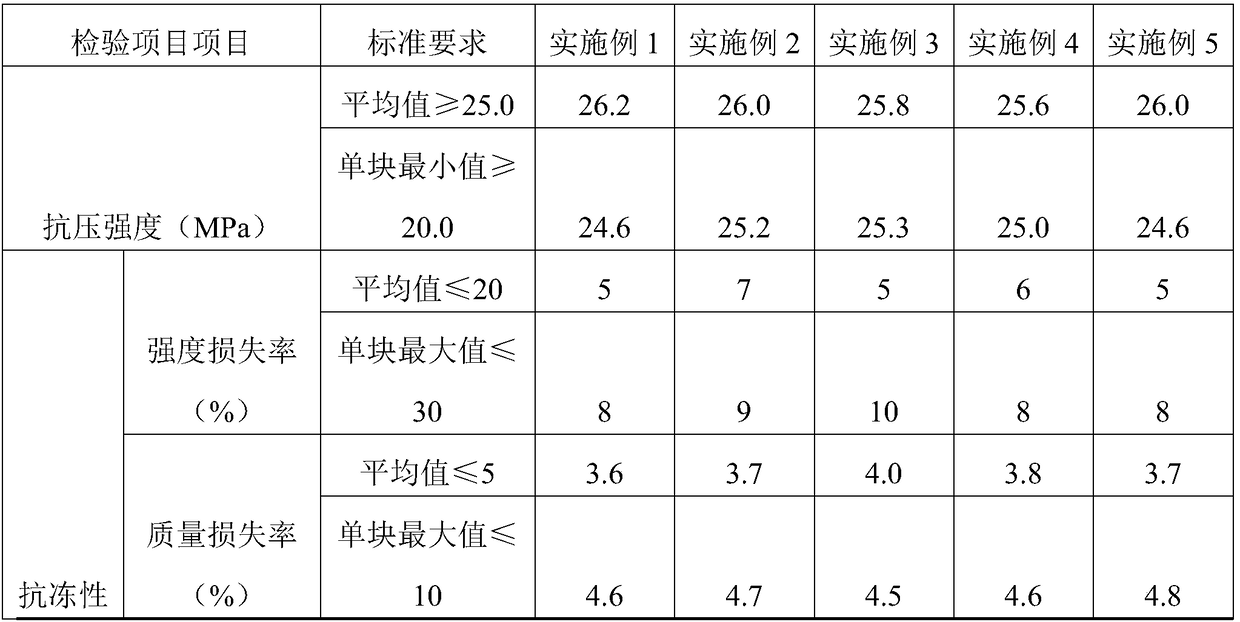

Examples

Embodiment 1

[0025] This embodiment provides a kaolinite antique brick, which is prepared from the following raw materials in parts by weight: 50 parts of kaolin slag, 8 parts of coal gangue, 8 parts of corn straw, 8 parts of fine sand, and 22 parts of sludge. Parts, 6 parts of salt gypsum, 6 parts of white cement, 1 part of silica fume, 0.7 parts of calcium chloride, 0.8 parts of calcium oxide, 0.8 parts of disodium EDTA.

[0026] The preparation method of kaolinite antique brick in this embodiment includes the following steps:

[0027] (1) Feed the corn stalks into the crusher, and then crush them for later use;

[0028] (2) After the coal gangue is screened and removed, it is sent to a crusher to be crushed, washed with water to remove debris and floating objects, and then reserved;

[0029] (3) Add the sludge to a forced mixer, and then add disodium EDTA. After forced stirring for 8 minutes, let it stand for 45 minutes; then weigh the kaolin slag, coal gangue, corn stalks, fine sand, and salt ...

Embodiment 2

[0033] This embodiment provides a kaolinite antique brick, which is prepared from the following raw materials in parts by weight: 45 parts of kaolin slag, 10 parts of coal gangue, 5 parts of corn stalks, 10 parts of fine sand, and 20 parts of sludge. Parts, 8 parts salt gypsum, 5 parts white cement, 2 parts silica fume, 0.5 parts calcium chloride, 1.0 parts calcium oxide, 0.5 parts disodium EDTA.

[0034] The preparation method of kaolinite antique brick in this embodiment includes the following steps:

[0035] (1) Feed the corn stalks into the crusher, and then crush them for later use;

[0036] (2) After the coal gangue is screened and removed, it is sent to a crusher to be crushed, washed with water to remove debris and floating objects, and then reserved;

[0037] (3) Add the sludge to a forced mixer, then add disodium EDTA, and after forced stirring for 5 minutes, let it stand for 60 minutes; then weigh kaolin slag, coal gangue, corn stalks, fine sand, and salt gypsum according t...

Embodiment 3

[0041] This embodiment provides a kaolinite antique brick, which is prepared from the following raw materials in parts by weight: 55 parts of kaolin slag, 5 parts of coal gangue, 10 parts of corn stalks, 5 parts of fine sand, and 25 parts of sludge. Parts, 5 parts of salt gypsum, 8 parts of white cement, 1.0 part of calcium chloride, 0.5 part of calcium oxide, 1.0 part of disodium EDTA.

[0042] The preparation method of kaolinite antique brick in this embodiment includes the following steps:

[0043] (1) Feed the corn stalks into the crusher, and then crush them for later use;

[0044] (2) After the coal gangue is screened and removed, it is sent to a crusher to be crushed, washed with water to remove debris and floating objects, and then reserved;

[0045] (3) Add the sludge to a forced mixer, then add disodium EDTA, and after forced stirring for 10 minutes, let it stand for 30 minutes; then weigh the kaolin slag, coal gangue, corn stalks, fine sand, and salt gypsum according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com