High-stability battledore frame and manufacturing process thereof

A badminton racket and high-stability technology, applied in the field of high-stability badminton racket frame and its manufacturing process, can solve problems such as insufficient stability and rigidity of the badminton racket frame, insufficient hitting feeling, and thick wall thickness of the racket frame. , to achieve the effect of stable rigidity, improved uniformity, and improved breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] A high-stability badminton racket frame and its manufacturing process, comprising the following steps:

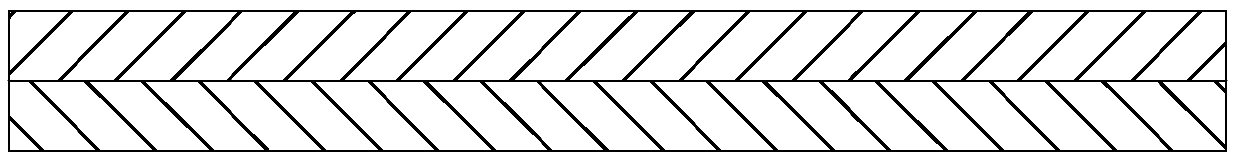

[0018] 1) Raw material preparation: the fiber weight per unit area is 37.5g / m 2 or 25g / m 2 carbon cloth, the single-layer thickness of the carbon cloth is 0.04mm or less than 0.03mm;

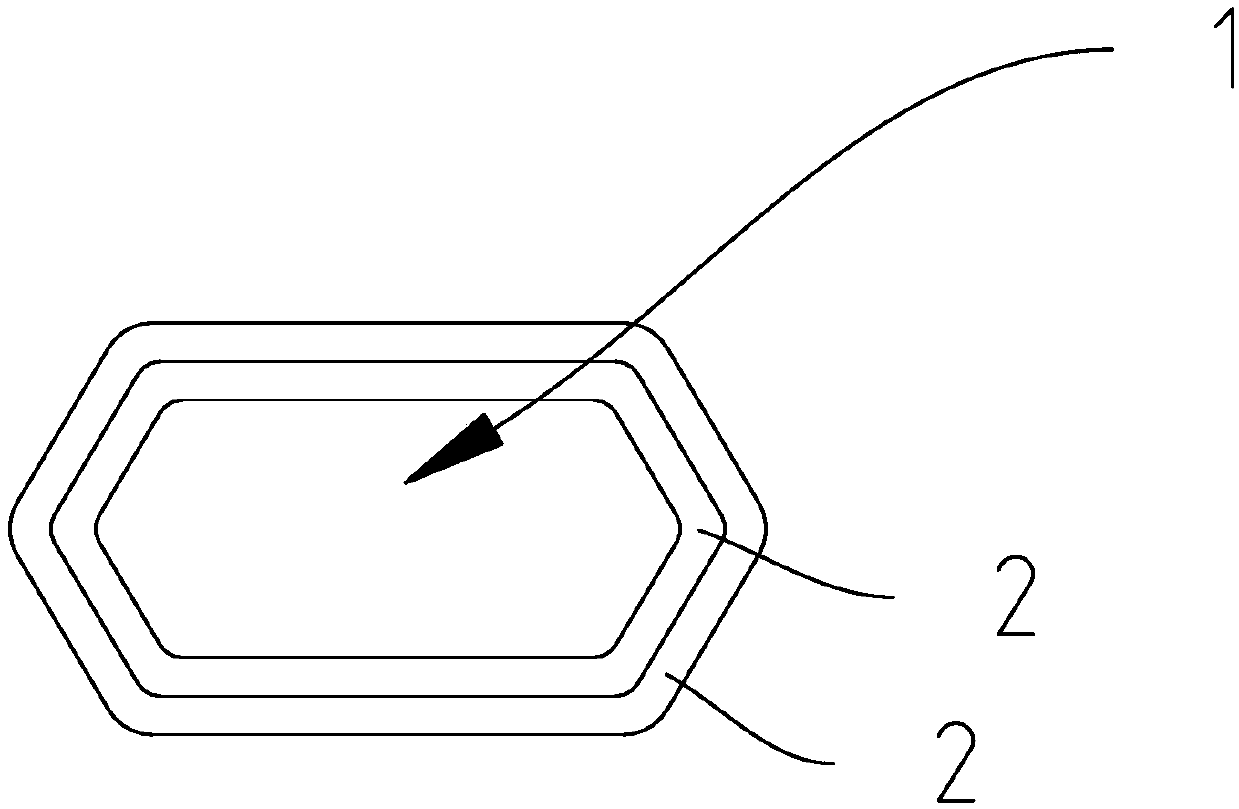

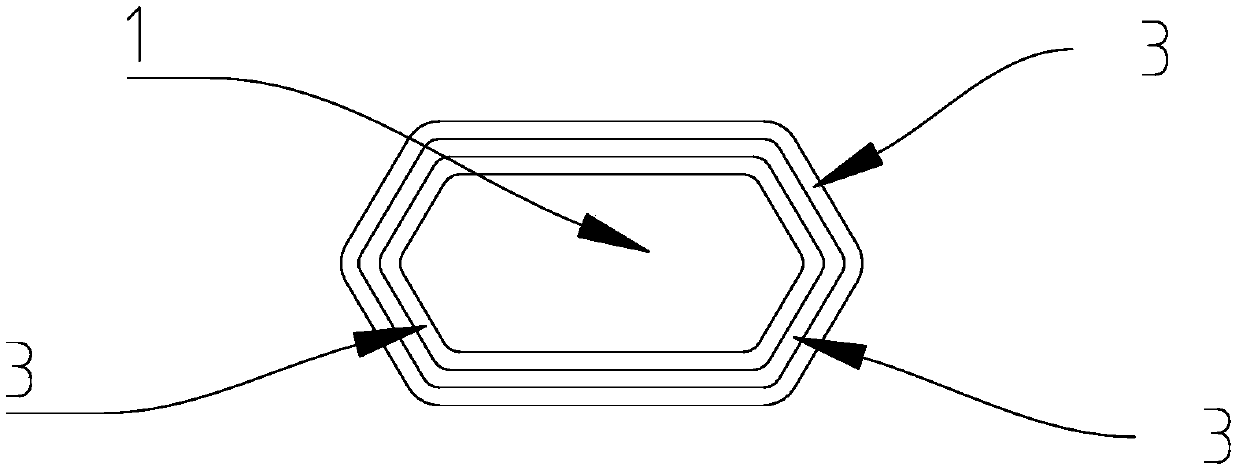

[0019] 2) Rolling racket frame: The above-mentioned carbon cloth is stacked to make double layers, and the double-layer carbon cloth is combined and pasted by stacking symmetrically, and rolled into a long strip through the core; the stacking is increased symmetrically The best method is to superimpose double-layer carbon cloth layer by layer, and stack three layers in total. The width of the three layers gradually decreases from the outer layer to the inner layer, and the innermost layer is the narrowest.

[0020] 3) Fix the rolled strip carbon cloth on the racket frame mold to make the initial shape of the badminton racket frame, and fix the joint between the middle tube and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com