Pitch diameter displaced screw

A thread and displacement technology, applied in the direction of threaded fasteners, nuts, bolts, etc., can solve the problems of strong pressure resistance and weak tensile force of threads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

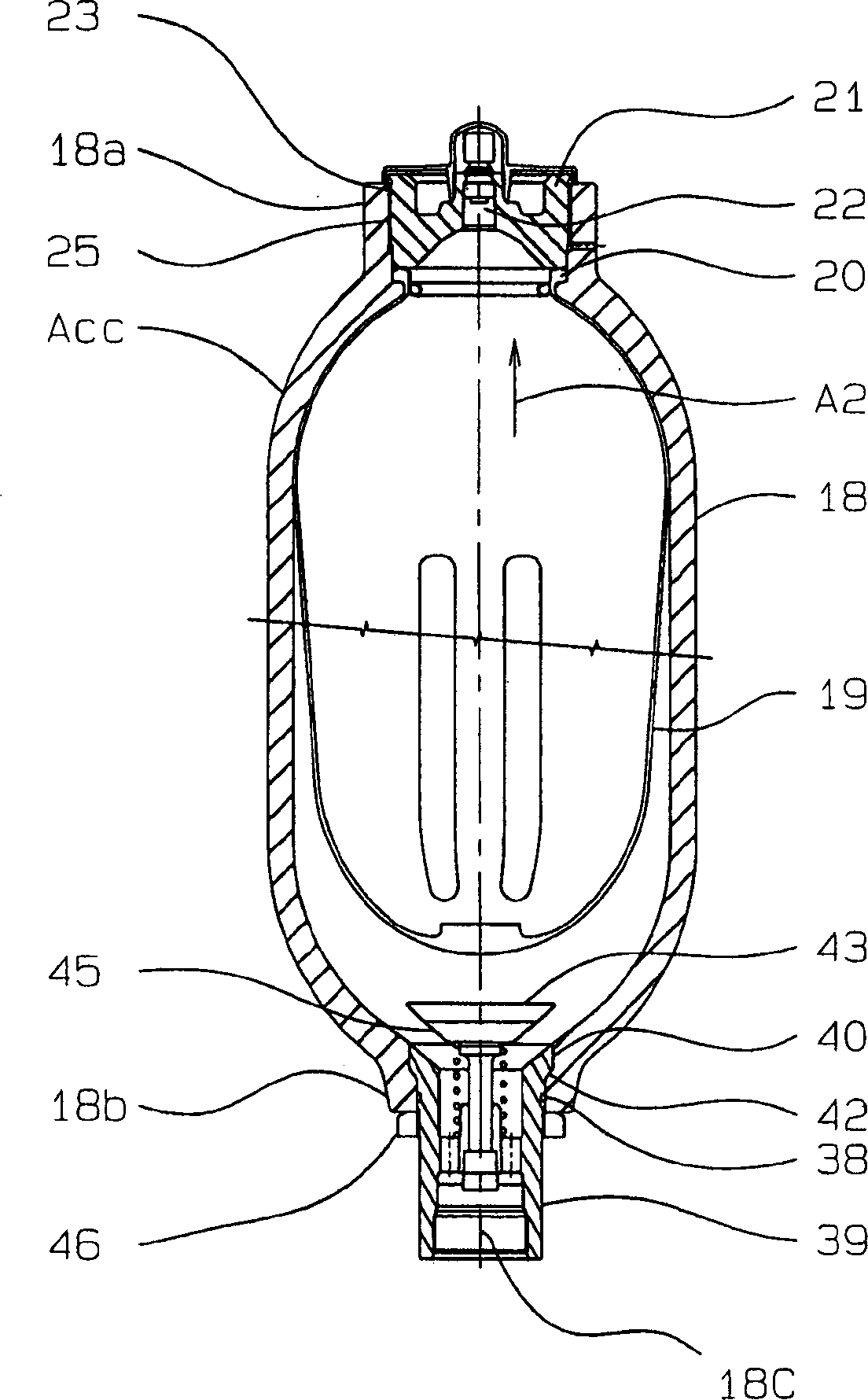

[0032] The present inventor uses the pressure accumulator (Nippon Accumulator Co., Ltd. (Nippon Akuumureta Co., Ltd.), model N210-1D) of the aforementioned first and second embodiments and the conventional example, and uses the finite element method to analyze the inner thread. The tensile stress value of the first thread root was analyzed, and the following results were obtained. Wherein, the aforementioned first thread root refers to the first thread root at the root of the internal thread that bears the load of the external thread first.

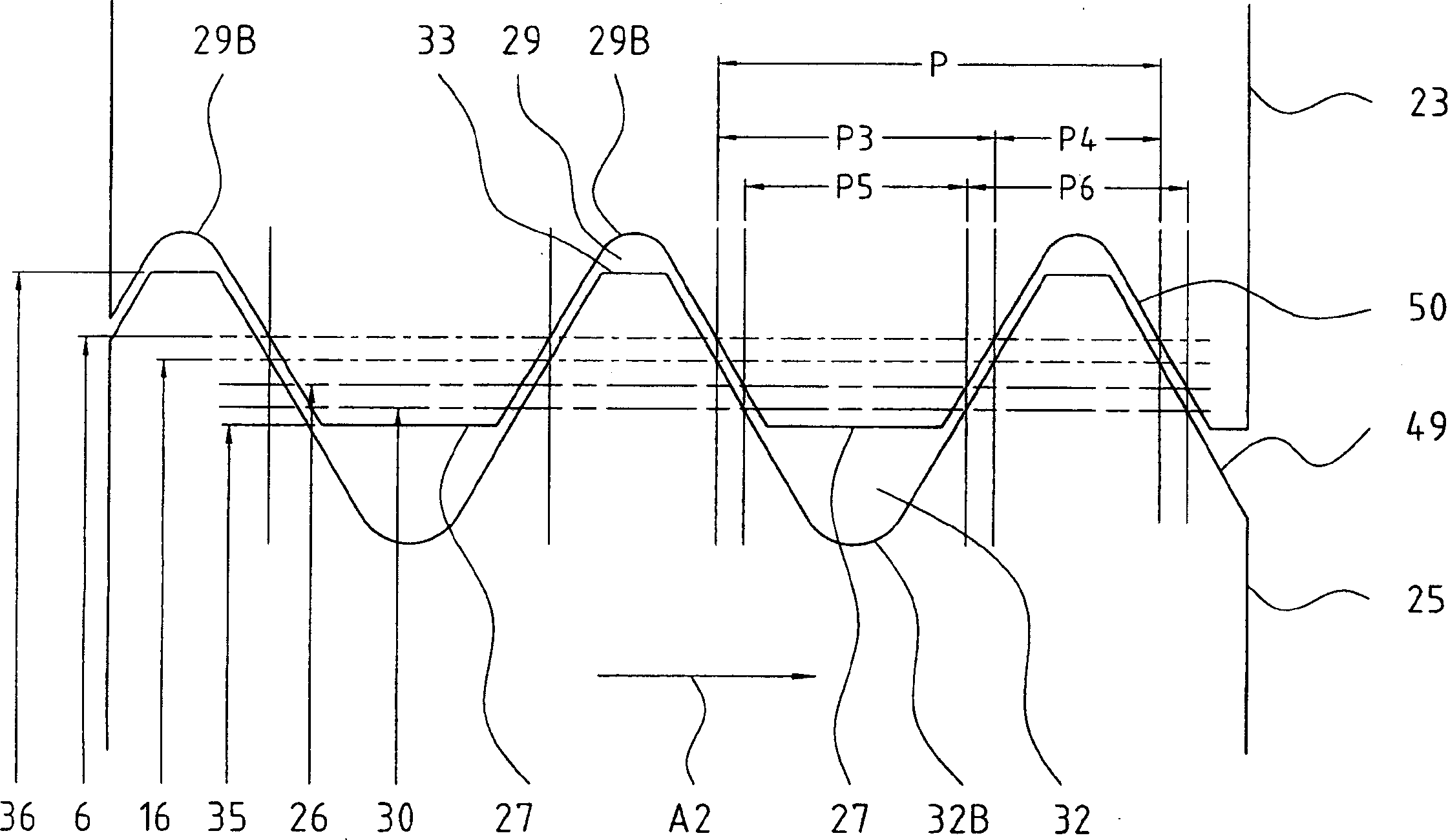

[0033] ·Existing example of metric internal thread (see Figure 4 ): 780N / mm 2

[0034] The metric internal thread of the present invention (see figure 1 ): 570N / mm 2

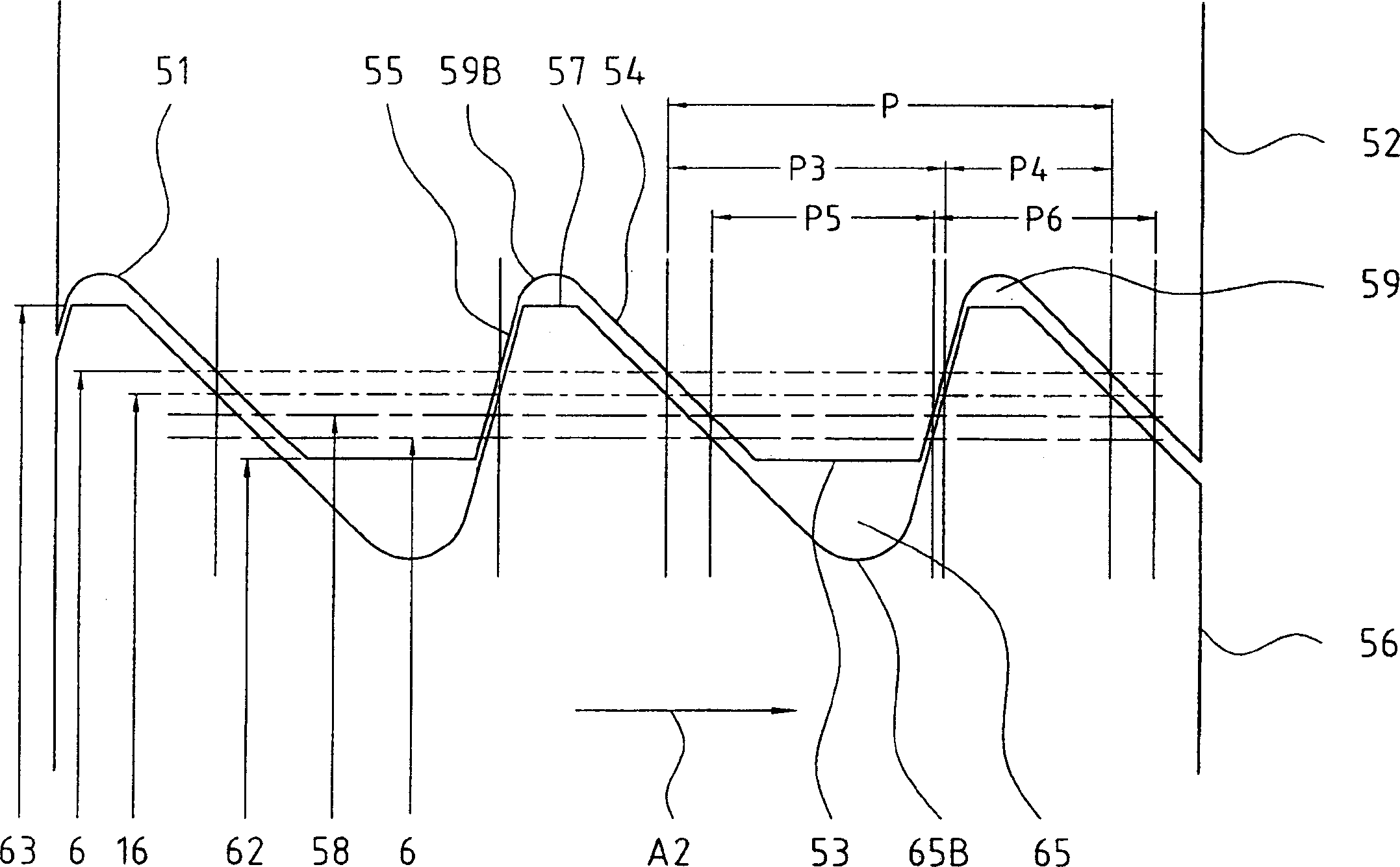

[0035] ·The inverted serrated internal thread of the existing example (see Figure 5 ): 592N / mm 2

[0036] ·The inverted sawtooth internal thread of the present invention (see image 3 ): 490N / mm 2

[0037] The above results clearly show that, for the metric int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com