Porcelain head type pin composite insulator and porcelain head bonding process thereof

A composite insulator, porcelain head type pin technology, applied in the field of power transmission and transformation, can solve the problem of difficulty in using pin type composite insulators on a large scale, and achieve the effects of shortening bonding time, firm bonding performance, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

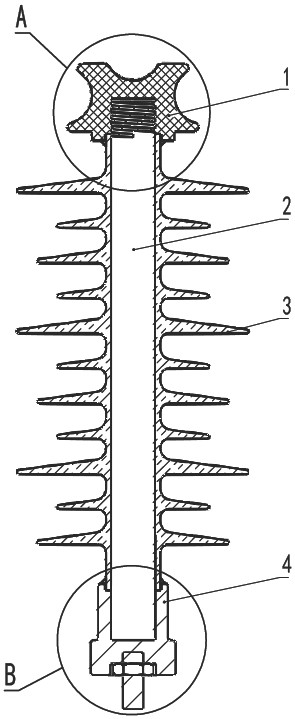

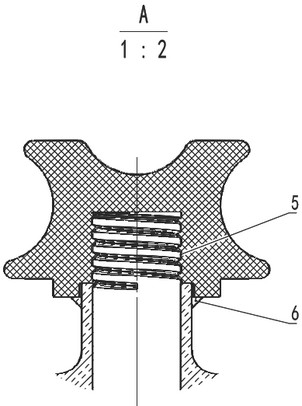

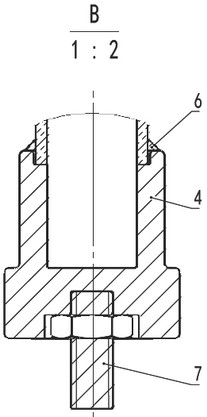

[0047] figure 1 Among them, the umbrella disc string 3 is coated on the cylindrical outer surface of the mandrel 2, and the umbrella disc string 3 includes a cylindrical tube sleeved outside the mandrel 2, an umbrella disc arranged on the outer wall of the cylindrical tube, and the mandrel 2 is light. One end is inserted into the 4 holes of the pin-type fittings, and the crimping machine is used for crimping and fixing. The threaded end is screwed into the small hole 1 of the porcelain head 1. When screwing in, the adhesive 5 is filled in the gap between the two, and the umbrella disc strings 3. The interfaces between the ceramic head 1 and the pin fitting 4 are all sealed with silicon rubber, and the central axes of the porcelain head 1, mandrel 2, pin fitting 4, and screw 7 are located on the same straight line. The mandrel 2 is made of epoxy glass fiber, and the umbrella disc string 3 is made of silicone rubber or resin; the outer surfaces of the pin fittings 4 and the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com