Hinge structure

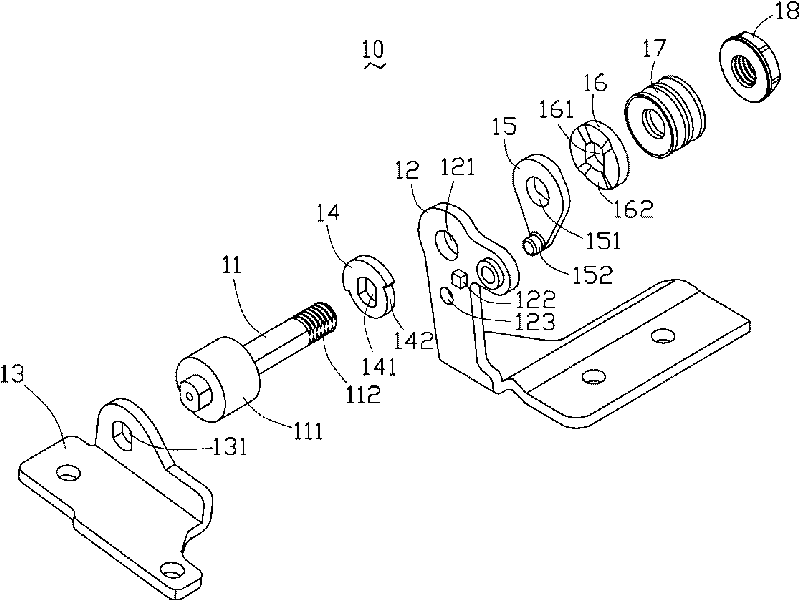

A hinge structure and limiter technology, which is applied to the structural parts of portable computers, instruments, electrical digital data processing and other directions, can solve the problems of the limit protrusion 122 being easily broken, affecting the rotation angle range, and poor impact resistance, etc. Achieve the effect of saving assembly space, good impact resistance, and high breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

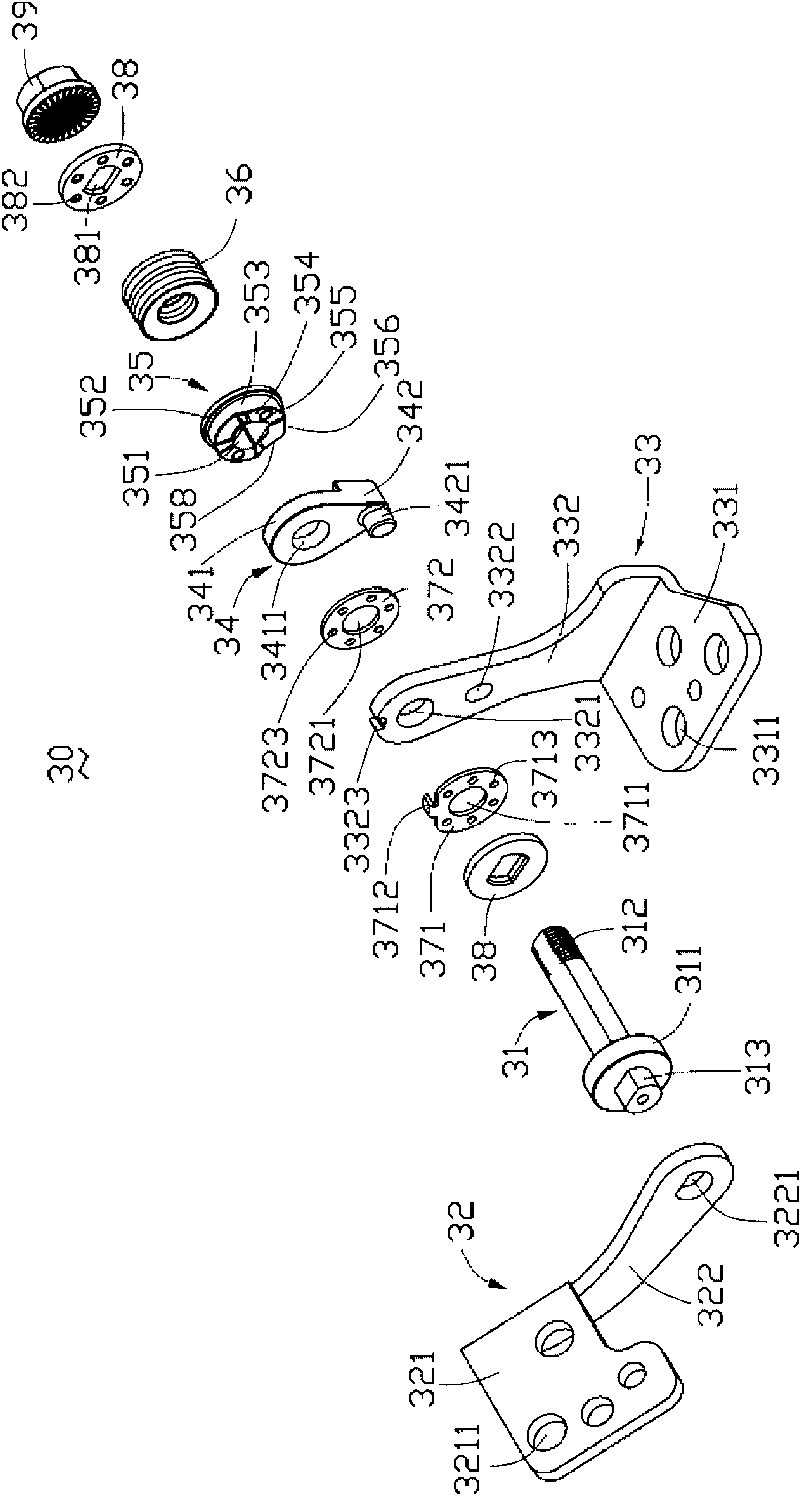

[0020] The hinge structure of the present invention will be further described in detail with reference to the accompanying drawings and preferred embodiments.

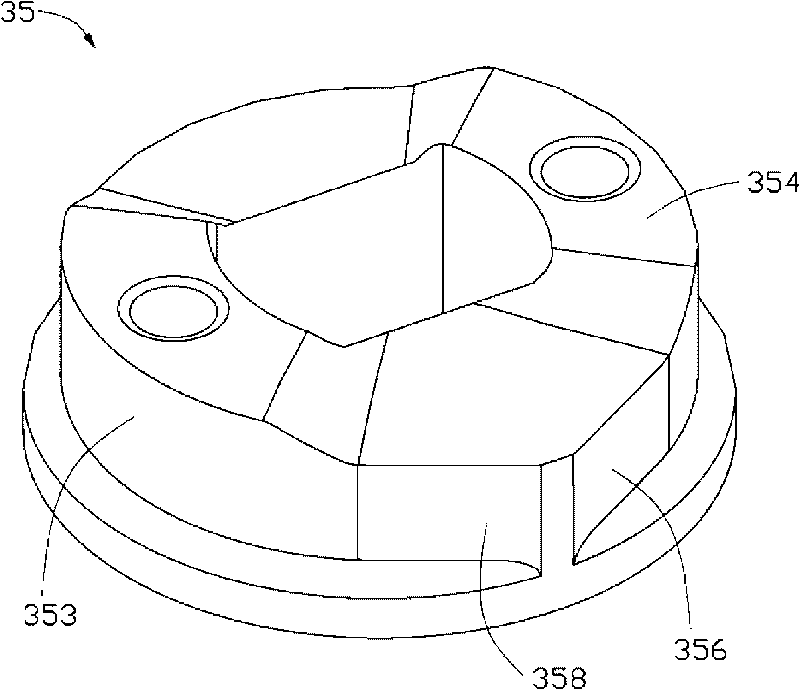

[0021] See also Figure 2 to Figure 4 , the hinge structure 30 of the present invention includes a pivot 31, a rotating bracket 32, a fixed bracket 33, a fixing piece 34, a limit piece 35, an elastic piece 36, a first friction plate 371, a second friction plate A piece 372, two gaskets 38 and a locking piece 39.

[0022] The pivot 31 has a non-circular cross-section, a disc-shaped flange 311 is formed at one end, and a threaded portion 312 is formed at the other end. One end of the pivot 31 forming the flange 311 further protrudes out of the flange 311 to form an inserting portion 313 .

[0023] The rotating bracket 32 includes a base plate 321 on which a plurality of fixing holes 3211 are defined. An arc-shaped positioning plate 322 extends from one side of the base plate 321 , and an end of the arc-shaped positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com