Preparation method of high-performance vacuum stone

A high-performance, vacuum technology, applied in the field of high-performance vacuum stone preparation, can solve the problems of no improvement in other properties of the vacuum stone in the preparation process and no vacuum stone, so as to enhance the mechanical properties, prevent agglomeration, and strengthen the failure strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

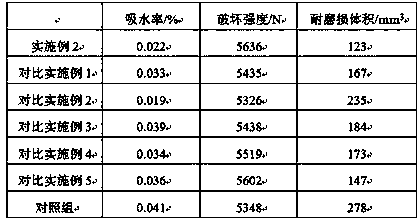

Examples

Embodiment 1

[0032] A preparation method of high-performance vacuum stone, comprising the steps of:

[0033] (1) Preparation of modified filler:

[0034] a. Put the pottery clay into a bead mill for grinding, grind at a speed of 800rpm for 30 minutes, and then pass through a 40-mesh sieve to obtain pottery clay powder for later use;

[0035] b. Put lanthanum nitrate into a bead mill for grinding, grind at a speed of 3000 rpm for 32 minutes and pass through a 200-mesh sieve to obtain lanthanum nitrate powder for subsequent use;

[0036] c. Mix the pottery clay powder obtained in operation a and the lanthanum nitrate powder obtained in operation b according to a weight ratio of 10:0.9 and put them into a calciner for calcination treatment. After calcination treatment for 34 minutes, cool to room temperature and take out the mixed powder for later use ;

[0037] d. Put the mixed powder and modified liquid obtained in operation c into the reaction kettle according to the weight volume ratio ...

Embodiment 2

[0055] A preparation method of high-performance vacuum stone, comprising the steps of:

[0056] (1) Preparation of modified filler:

[0057] a. Put the pottery clay into a bead mill for grinding, grind at a speed of 850 rpm for 35 minutes, and then pass through a 60-mesh sieve to obtain pottery clay powder for later use;

[0058] b. drop lanthanum nitrate into a bead mill for grinding, grind at a speed of 3200rpm for 36min and pass through a 250 mesh sieve to obtain lanthanum nitrate powder for subsequent use;

[0059] c. Mix the pottery clay powder obtained in operation a and the lanthanum nitrate powder obtained in operation b according to the weight ratio of 12:0.85 and put them into a calciner for calcination treatment. After calcination treatment for 37 minutes, cool to room temperature and take out the mixed powder for later use ;

[0060] d. Put the mixed powder and modified solution obtained in operation c into the reaction kettle according to the weight volume ratio...

Embodiment 3

[0078] A preparation method of high-performance vacuum stone, comprising the steps of:

[0079] (1) Preparation of modified filler:

[0080] a. Put the pottery clay into a bead mill for grinding, grind at a speed of 900 rpm for 40 minutes, and then pass through a 80-mesh sieve to obtain pottery clay powder for later use;

[0081] b. drop lanthanum nitrate into a bead mill for grinding, and grind at a speed of 3400rpm for 40 minutes to pass through a 300-mesh sieve to obtain lanthanum nitrate powder for subsequent use;

[0082] c. Mix the pottery clay powder obtained in operation a and the lanthanum nitrate powder obtained in operation b according to a weight ratio of 14:0.8 and put them into a calciner for calcination treatment. After calcination treatment for 40 minutes, cool to room temperature and take out the mixed powder for later use ;

[0083] d. Put the mixed powder and modified liquid obtained in operation c into the reactor according to the weight volume ratio of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com