Powder composition for refractory castable and refractory castable equipped therewith

A technology of refractory castables and compositions, which is applied in the field of powder compositions for refractory castables and refractory castables. It can solve the problems of high destructive strength and achieve high destructive strength, low thermal conductivity, light weight and thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

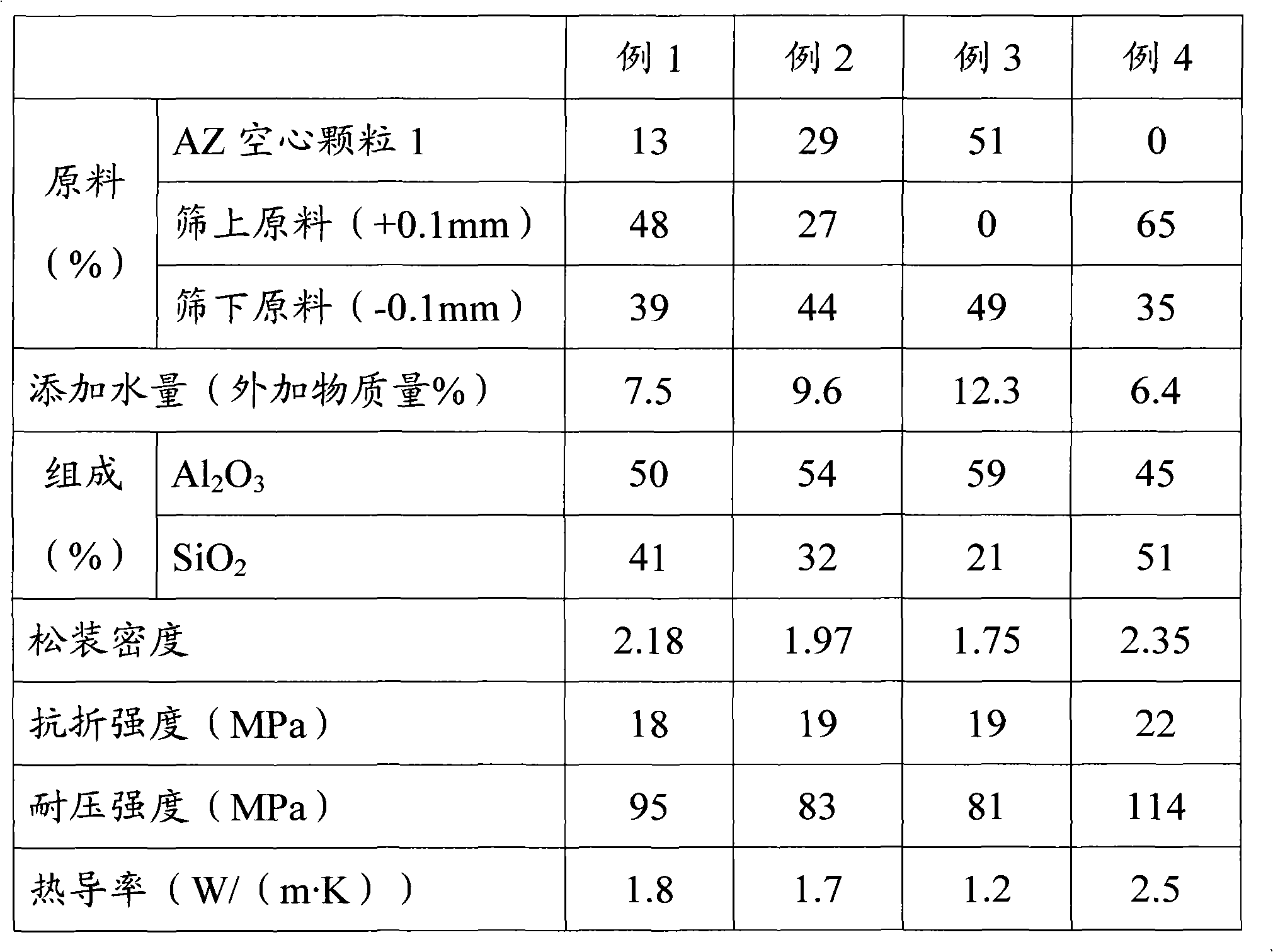

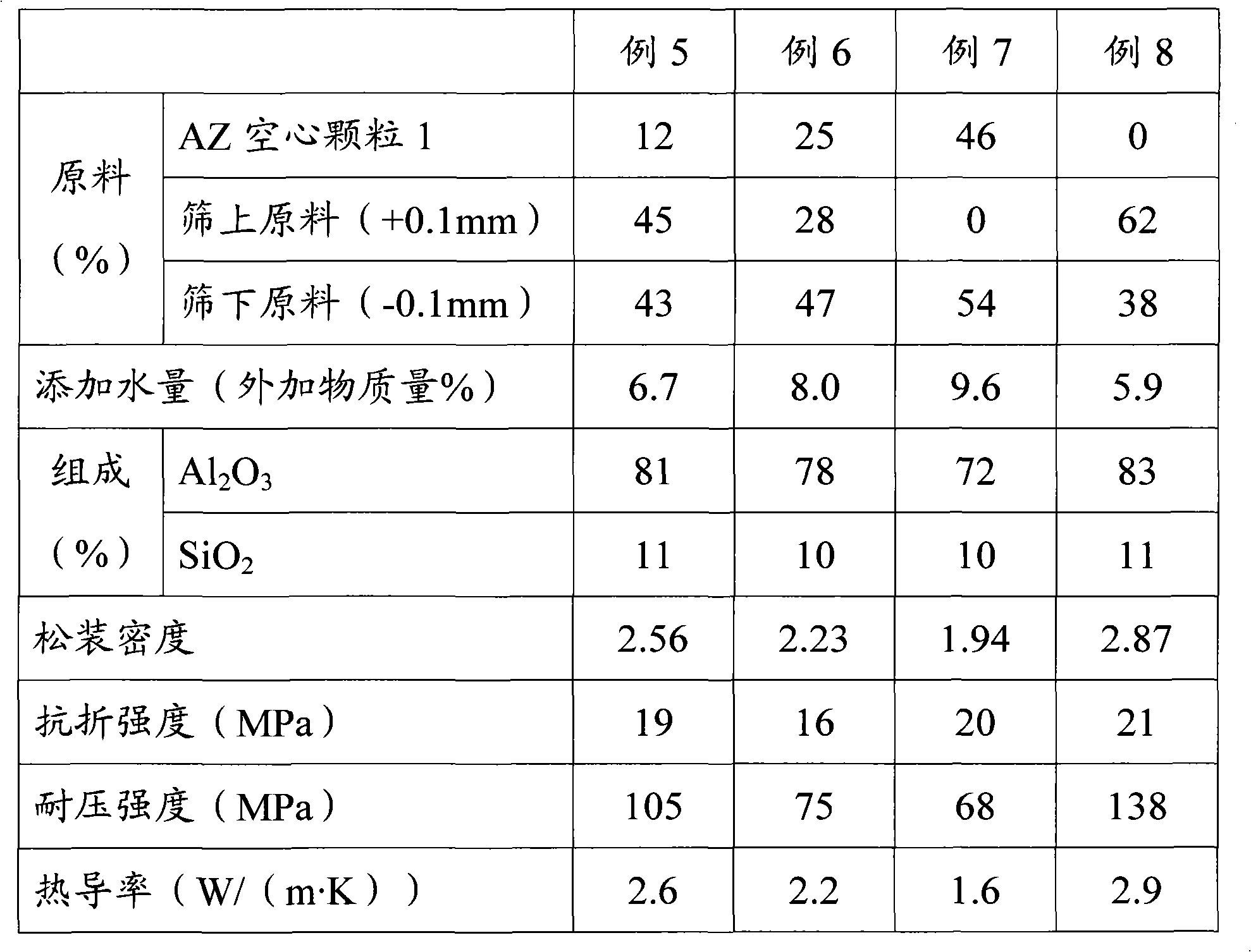

[0052] Hereinafter, examples of the refractory castable of the present invention are used as examples (Example 1 to Example 3, Example 5 to Example 7) and examples of conventional refractory castables are used as comparative examples (Example 4 and Example 8). . In addition, this invention is not limited to these Examples.

[0053] Preparation of Lightweight Refractory Aggregate

[0054] The inner diameter of the furnace is 800mm, the height is 600mm, and the inner volume of the furnace is 0.6m 3 The electric arc melting furnace is used as a test furnace, and a 500kVA one is used as a transformer. In addition, the lining refractory material of the melting furnace uses Al 2 o 3 Electroformed refractories with a content of more than 97%.

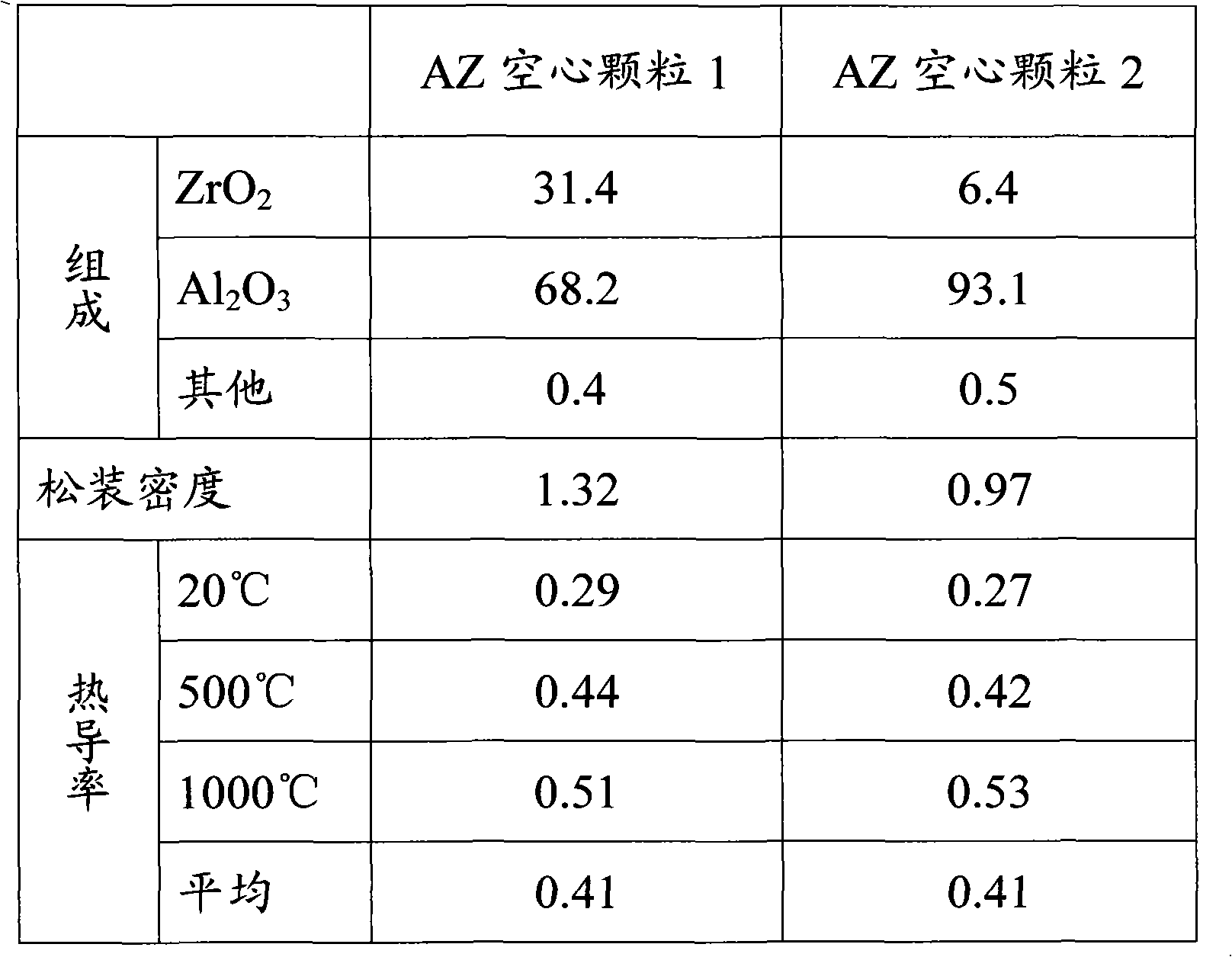

[0055] as Al 2 o 3 The raw material uses Bayer alumina (Bayer alumina) with a purity of 99.3% or more as ZrO 2 Fused zirconia cullets with a purity of 99.5% or more are used as raw materials, and these raw materials are mixed into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com