Additive-manufacturing-oriented pulmonary alveolar bionic super heat exchanger structure and production method thereof

An additive manufacturing and heat exchanger technology, applied in the directions of additive manufacturing, additive processing, heat exchange equipment, etc., can solve the problem of heat exchangers and connecting pipes occupying production space, poor heat exchange effect, small heat exchange area, etc. problems, to achieve the effect of enhancing the anti-destructive ability, improving the heat exchange effect, and large heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention is a method for preparing an alveolar bionic super heat exchanger structure oriented to additive manufacturing technology. Firstly, the data model of the alveolar bionic super heat exchanger structure oriented to additive manufacturing technology is drawn, and then the cross-section of the data model is digitalized. Slice to obtain the slice data, import the slice data into the 3D printer, select the metal powder raw material according to the situation, and process it through the 3D printer to form a super heat exchanger structure based on the alveolar tissue structure for additive manufacturing. The specific steps are as follows:

[0054] S1. Determine the adjustable geometric parameters related to the structure of the alveolar bionic super heat exchanger according to specific needs and actual conditions, draw the three-dimensional data model of the structure through the commercial three-dimensional modeling software UG, and convert the obtained thr...

Embodiment 1

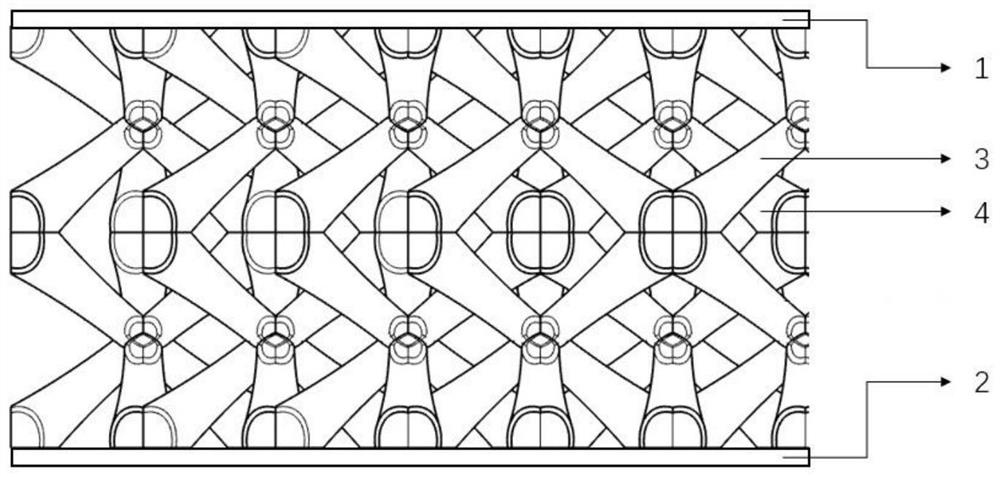

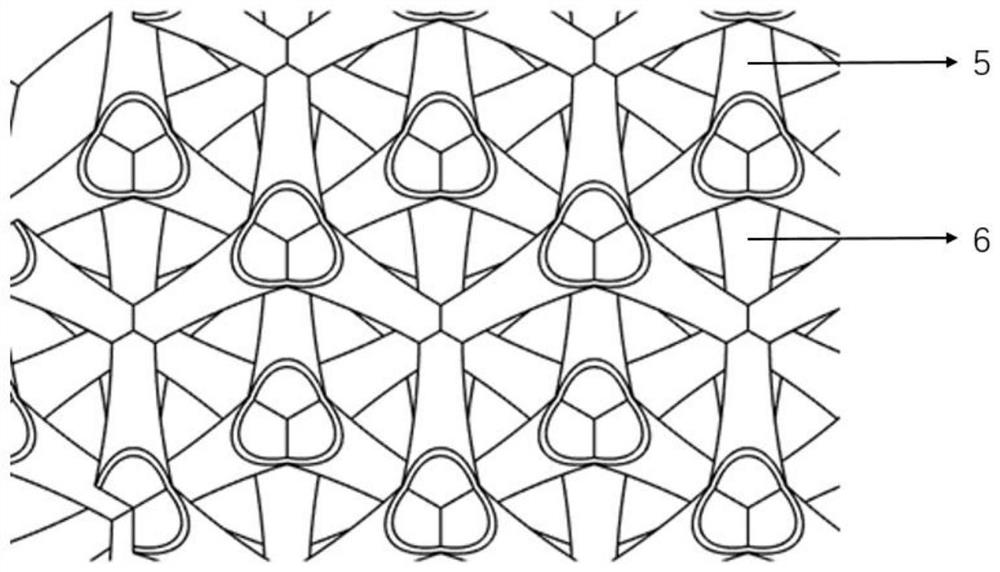

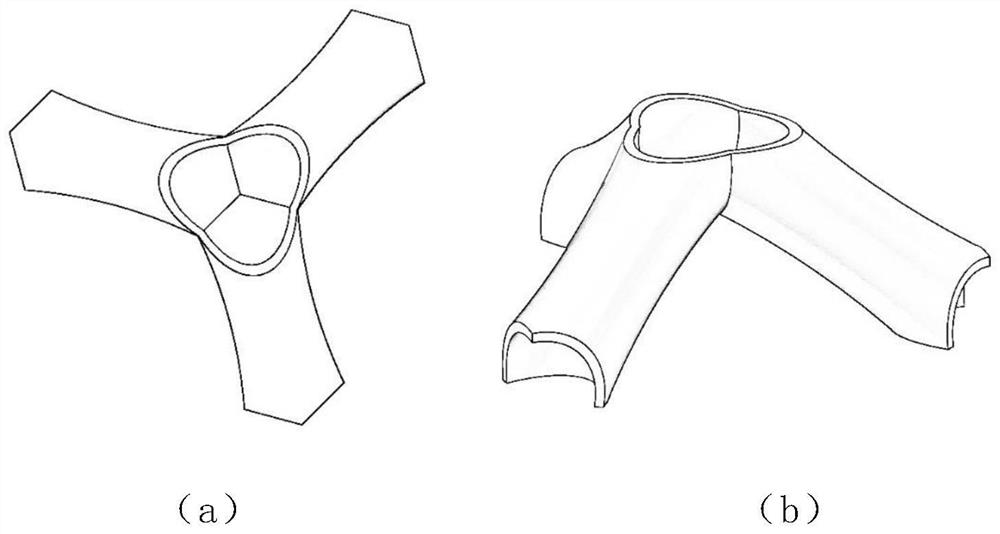

[0059] (1) Use the commercial 3D modeling software UG to draw a 3D data model of the alveolar bionic super heat exchanger structure for additive manufacturing technology. The side panel is a rectangular plate with a side length of 16.4mm, a height of 22.9mm, and a thickness of 1mm; the structural unit cell of the super heat exchanger forming the core body is shown in the following geometric model figure 2 , the radius of the widest part at both ends of the pipe is 4mm, the central curvature is 50mm, the angle between the pipe and the vertical direction is 45°, the length of the pipe is 20mm, and the thickness is 0.5mm. Convert the drawn 3D data model into STL format data and export it.

[0060] (2) Import the STL format data obtained in the previous step into the commercial model dissection software Cura, carry out digital cross-sectional slices to the three-dimensional data model, and obtain the slice data of the three-dimensional data model;

[0061] (3) Import the slice d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com