Multi-stage anti-impact supporting column

An anti-scour and pillar technology, applied in the direction of pillar/support, mining equipment, earth-moving drilling, etc., can solve the problems of slowing down the production progress, roadway collapse, burst and fracture, etc., to enhance the anti-destructive strength, energy absorption and anti-scour Powerful, Simple Design Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

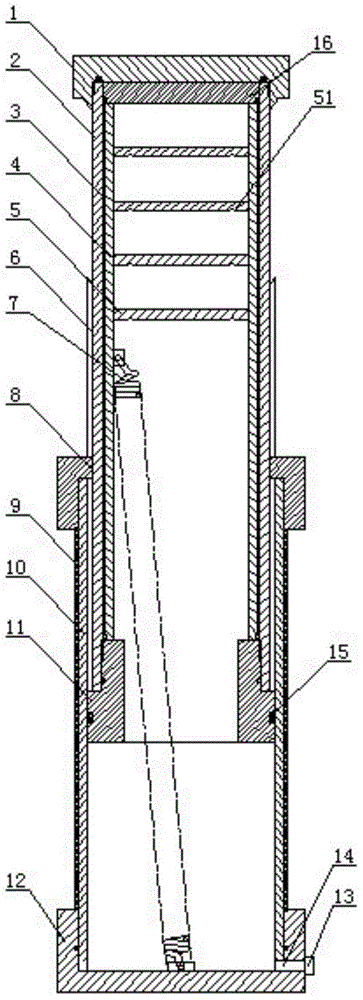

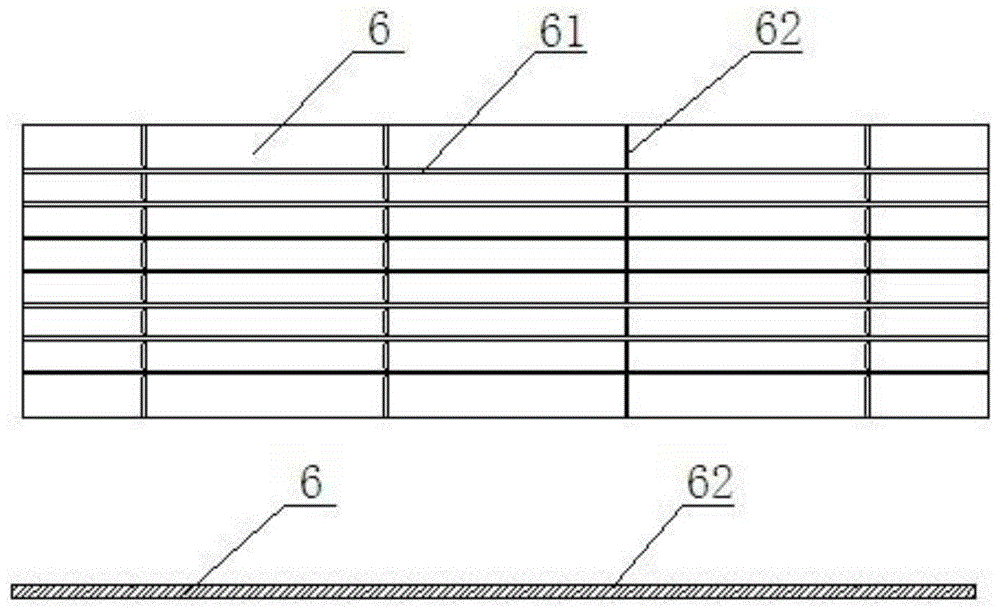

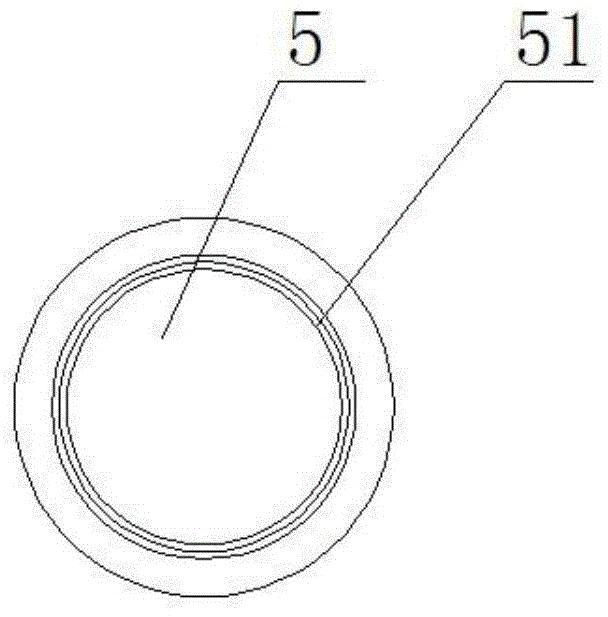

[0020] Examples, see attached figure 1 A multi-stage anti-shock pillar shown includes a top cover 1, a hydraulic column 2, a piston 11, a return spring 7, a hydraulic cylinder top cover 8, an alloy hydraulic cylinder 10, a hydraulic cylinder base 12, and a three-purpose valve 13; the hydraulic column The top of 2 is connected to the top cover 1, and the bottom is connected to the piston 11. A guide groove is arranged on the outer surface of the piston 11, and a piston sealing ring 15 is arranged in the guide groove, which plays a hydraulic sealing effect on the alloy hydraulic cylinder 10. The hydraulic column 2 is nested inside the alloy hydraulic cylinder 10, the top of the alloy hydraulic cylinder 10 is provided with a hydraulic cylinder top cover 8, and the bottom is fixedly connected with the hydraulic cylinder base 12; the outer surface of the allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com