Clamping device for computer shell machining

A technology for clamping devices and shells, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high cost, complex structure, poor pressing quality, etc., and achieve high clamping efficiency and low cost Inexpensive, good clamping quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

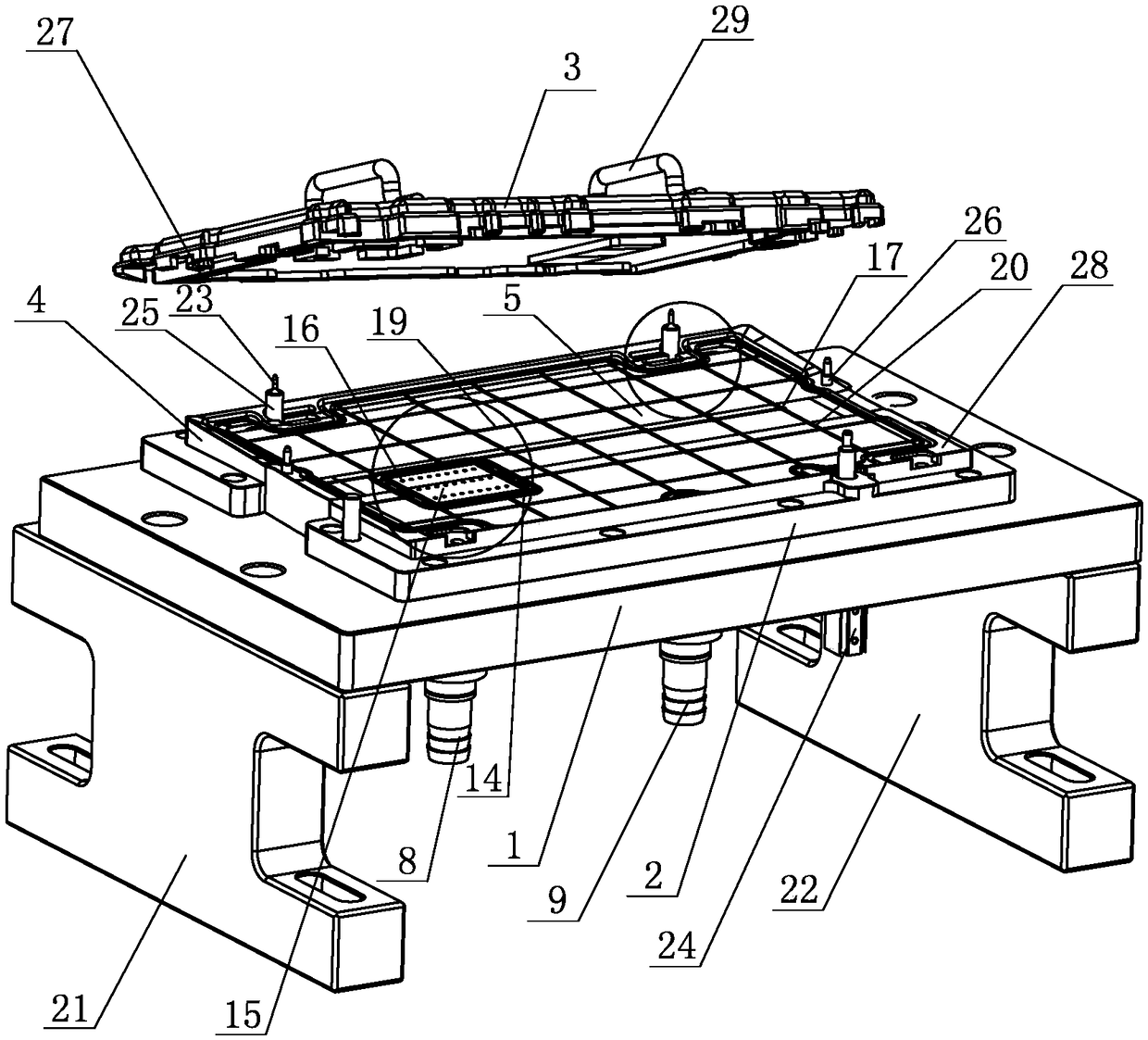

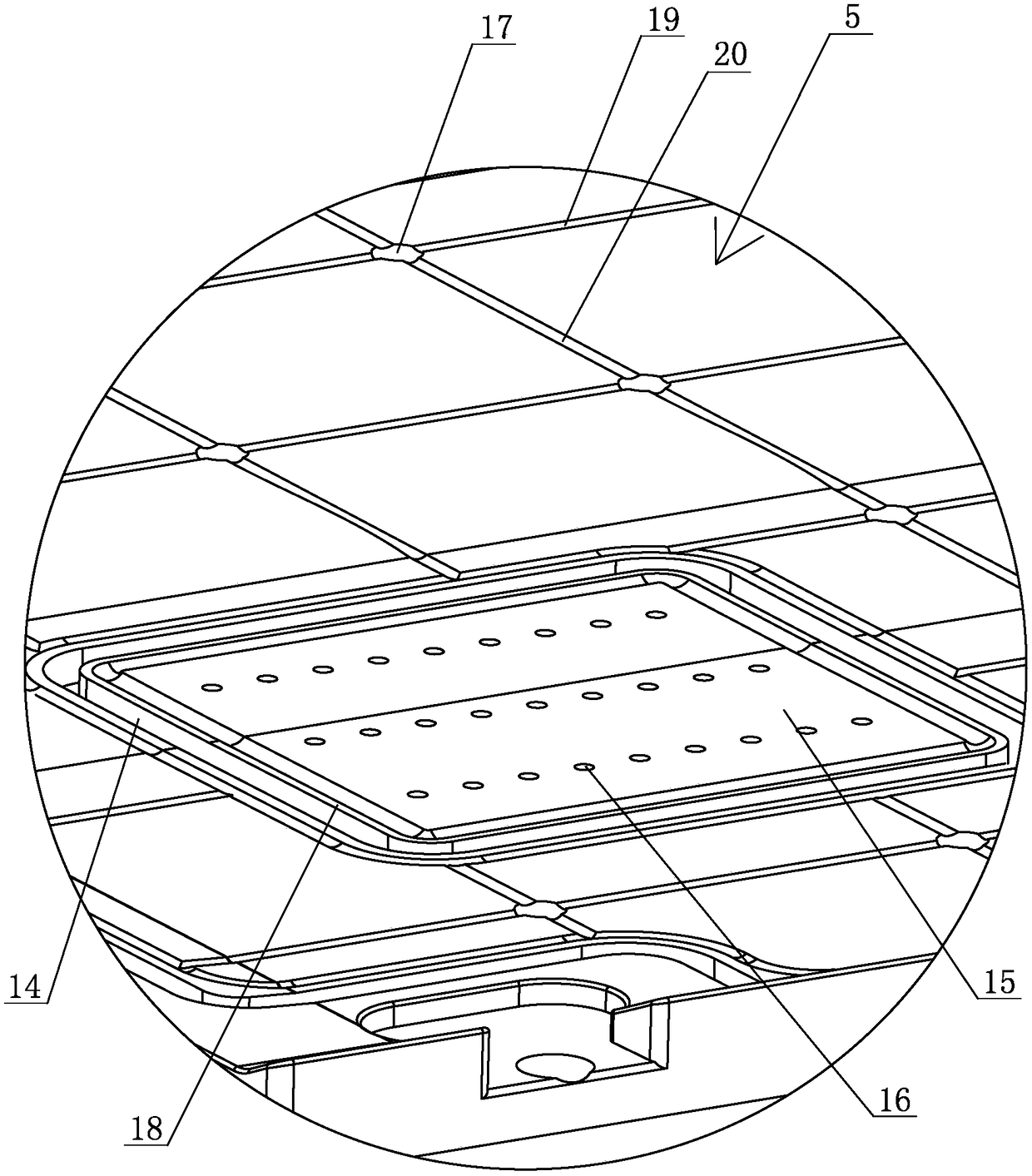

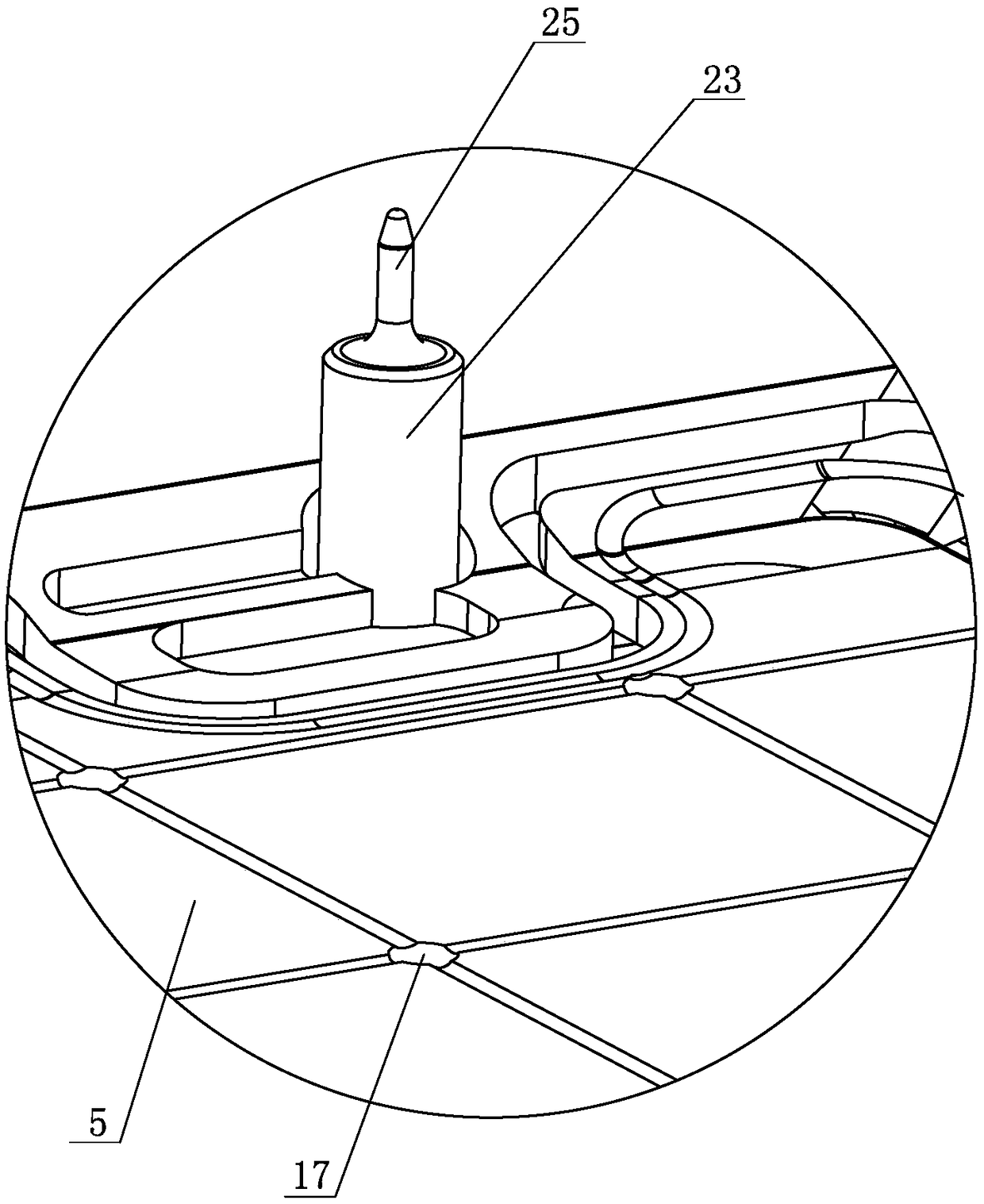

[0021] Embodiment one: see Figure 1~4 As shown, a clamping device for computer case processing includes a bracket, a fixed plate 1, a product carrying plate 2 and a pressing plate 3, the bottom of the fixed plate 1 is installed on the support, and the product carrying plate 2 The bottom is installed on the top surface of the fixed plate 1, and the pressing plate 3 is placed on the product carrying plate 2; a raised block 4 is arranged on the top surface of the product carrying plate 2, and the raised block 4 A product placement groove 5 is provided on the top surface of the top surface, and the bottom surface of the pressing plate 3 is placed on the top outer edge surface of the raised block 4; the fixed plate 1 is provided with a left through hole 6 and a right through hole. hole 7, a first vacuum joint 8 is installed in the left side through hole 6, a second vacuum joint 9 is installed in the right side through hole 7, and the first vacuum joint 8 and the second vacuum join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com