Mixing blade pressing tool and pressing process

A stirring blade and tooling technology, applied in the field of stirring blade pressing tooling and pressing technology, can solve the problems of shortening the service life of the stirring blade, the stirring blade is easy to touch the inner wall of the kettle, and the materials cannot be fully stirred, so as to improve the processing quality and improve the The effect of processing efficiency and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

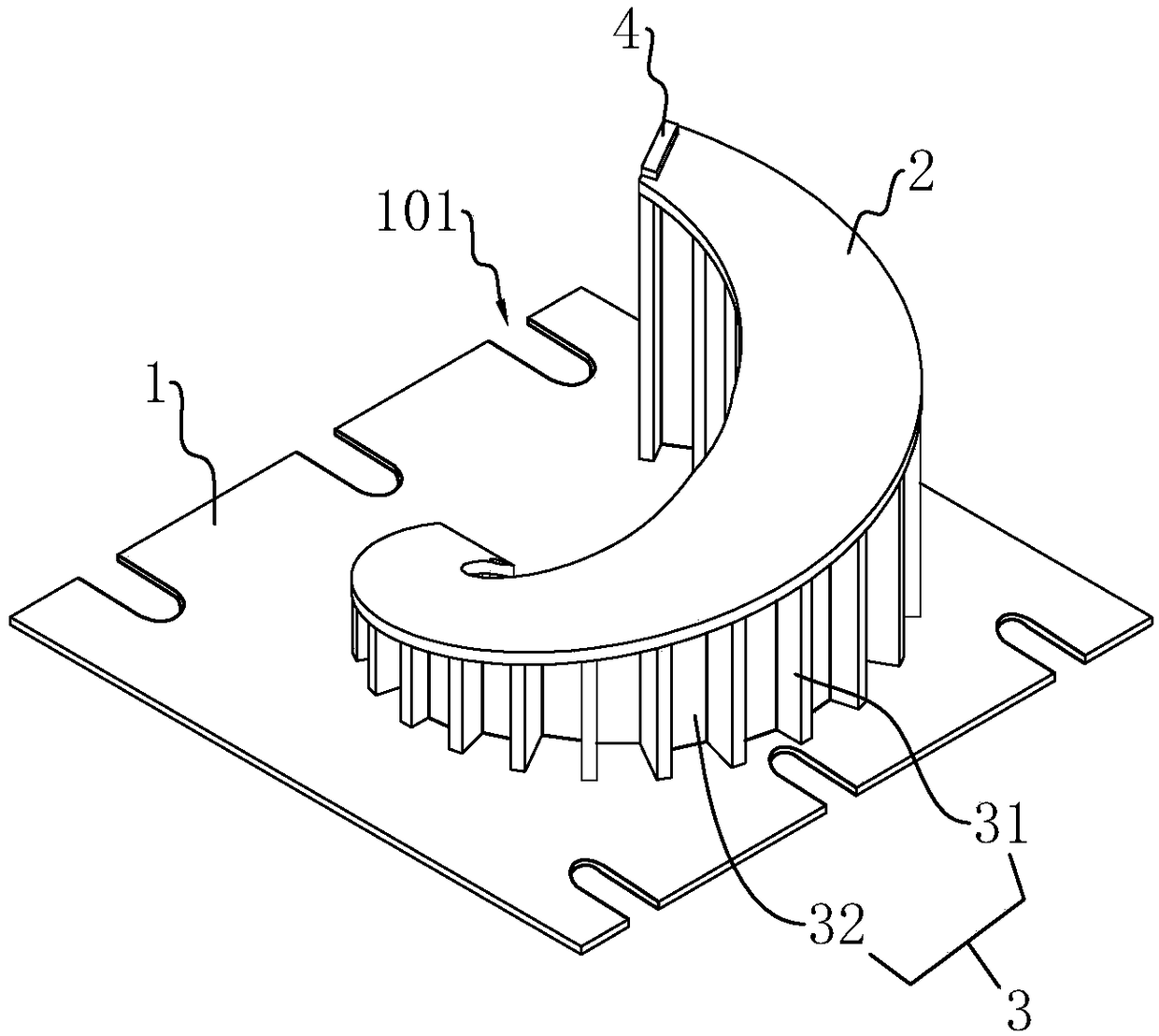

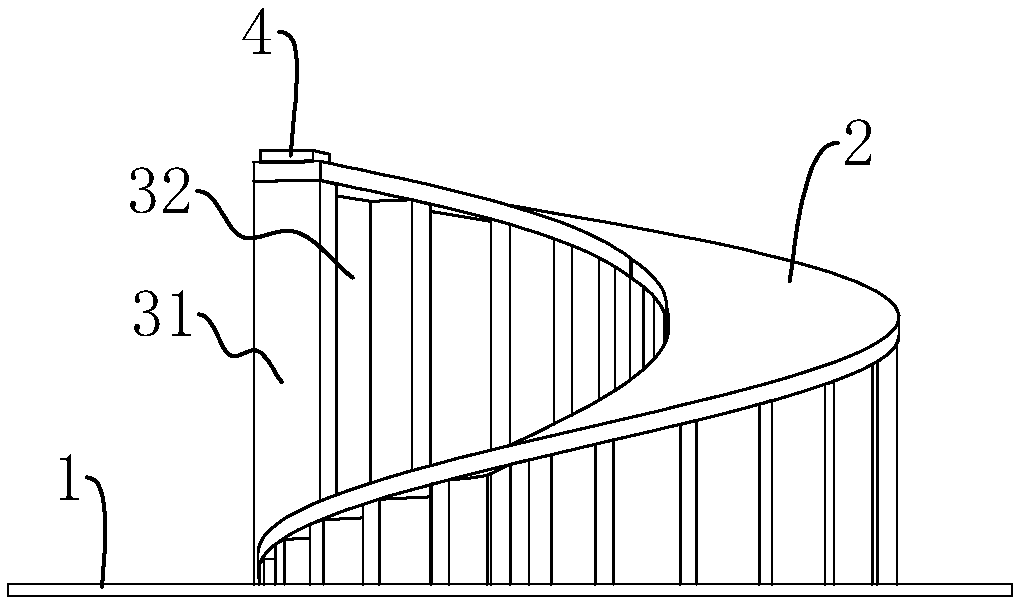

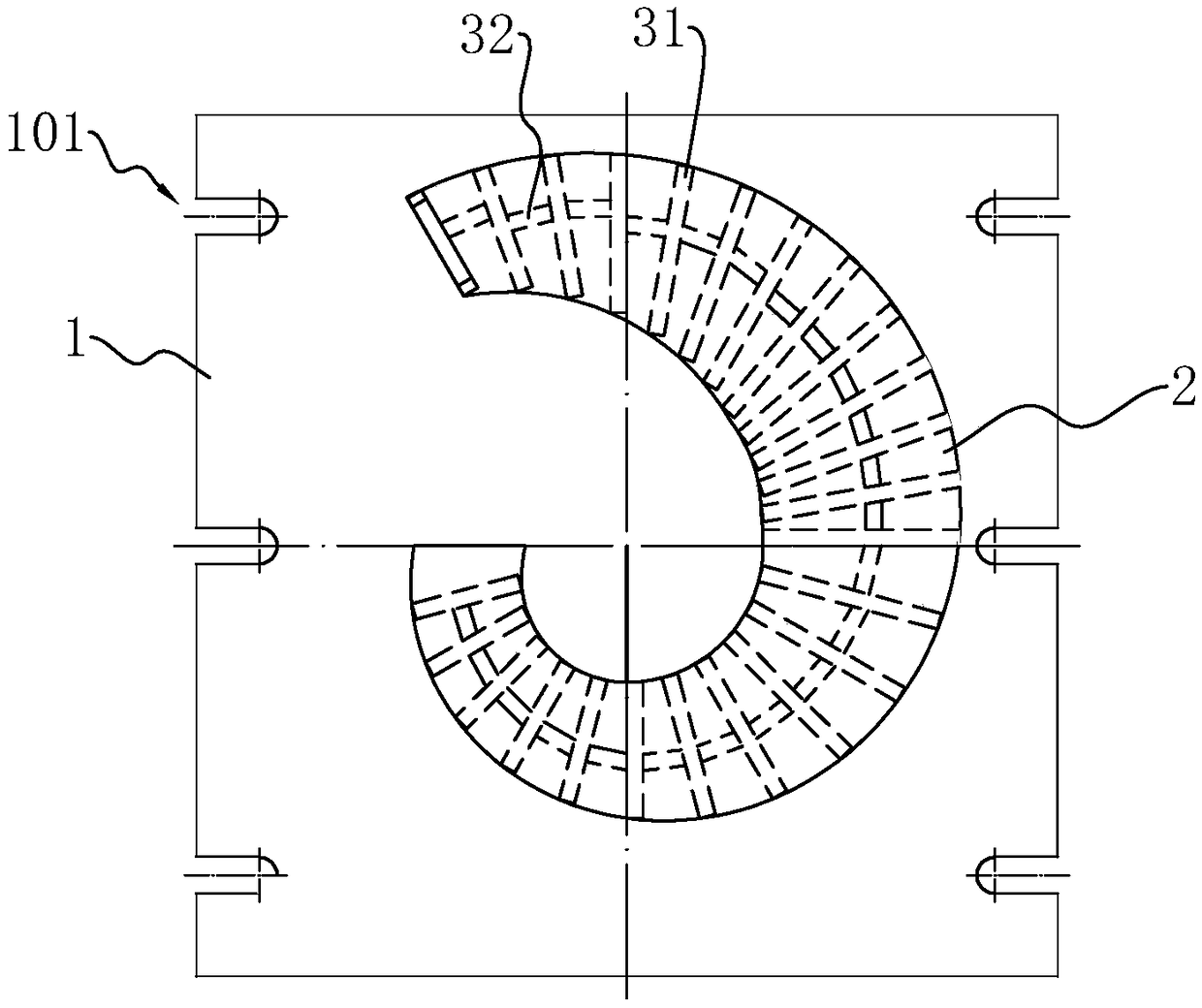

[0043] See attached figure 1 , a mixing blade pressing tool, including a base 1, the base 1 can be a square steel plate, the base 1 is provided with a fixed groove 101, and multiple sets of the fixed groove 101 can be arranged symmetrically on any opposite sides of the base 1; in actual installation , the fixing groove 101 cooperates with the anchor bolts to stably fix the base 1 on the ground to ensure the stability of the base 1 . A tooling blade 2 is arranged on the top of the base 1, and the tooling blade 2 is in a spiral structure, and its shape and size are consistent with the mixing blades to be processed. At the same time, a supporting assembly 3 for supporting the tooling blade 2 is also fixed on the base 1 , and the tooling blade 2 is fixedly arranged on the top of the supporting assembly 3 . The upper surface of the tooling blade 2 is welded with a positioning block 4, which can be arranged on the upper edge of the tooling blade 2, and the edge on one side in the w...

Embodiment 2

[0048] See attached figure 1 And attached Figure 4 , a mixing blade pressing process, comprising the steps of:

[0049] S1. According to the design size of the mixing blade, pre-segment the mixing blade, and unfold the sample of each sub-blade to obtain the shape and size of each sub-blade after expansion.

[0050] When manufacturing large-scale mixing equipment, due to the relatively large overall size of the corresponding mixing blade, the existing processing capacity is insufficient, so the mixing blade should be reasonably segmented according to the design size of the mixing blade to form multi-section blades, and then in each segment After the sub-blades are processed, they are aligned and integrated to obtain a complete mixing blade. In this way, the processing difficulty of the large stirring blade can be reduced, and the processing efficiency and processing quality of the large stirring blade can be improved.

[0051] In the actual processing process, in order to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com