Automatic uncoiling and tensioning equipment for rail car body skin

A rail car and tensioning technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as uneven stress distribution, poor safety and reliability, and injury to people, and achieve a reduction in the number of labor and costs, and a reasonable and compact structural design , The effect of uniform distribution of pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

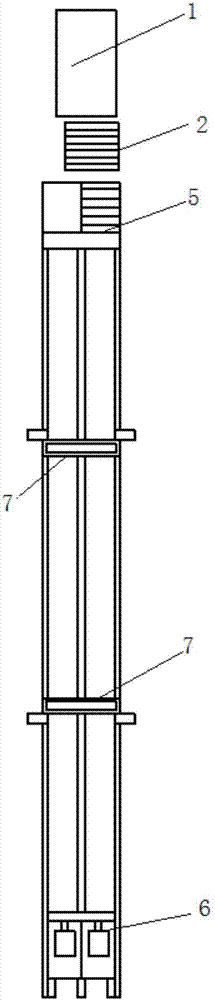

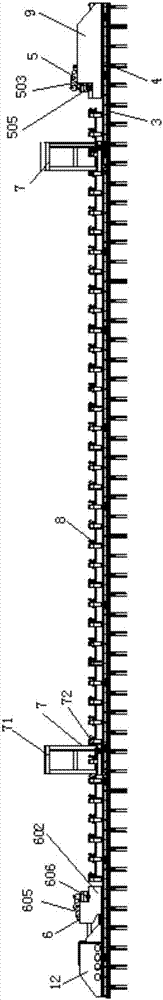

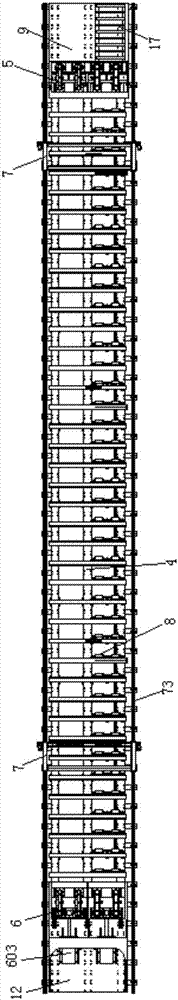

[0024] Attached below Figure 1-9 An embodiment of the present invention is described.

[0025]The automatic uncoiling and tensioning equipment for rail car body skin has an uncoiler 1, a leveling machine 2 and a shearing and tensioning assembly. The shearing and tensioning assembly includes a foundation longitudinal beam 3, a movable platform 4, Shearing and pressing device 5, pressing and tensioning device 6 and skeleton positioning and pressing device 7, the movable platform 4 is fixed on the foundation longitudinal beam 3 and the roller way 8 convenient for transporting steel plates is laid on the movable platform 4, the movable platform 4 The left end of the platform 4 is provided with a compression and tension device 6 and the shear and compression device 5 located at the right end of the movable platform 4 is fixedly connected with the foundation longitudinal beam 3, and two A frame positioning and pressing device 7 with adjustable position, the leveler 2 and the uncoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com