Copper bush press-mounting machine

A technology of pressing machine and copper sleeve, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency of copper sleeve pressing, and achieve the goal of reducing labor intensity of workers, realizing operation automation and improving production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

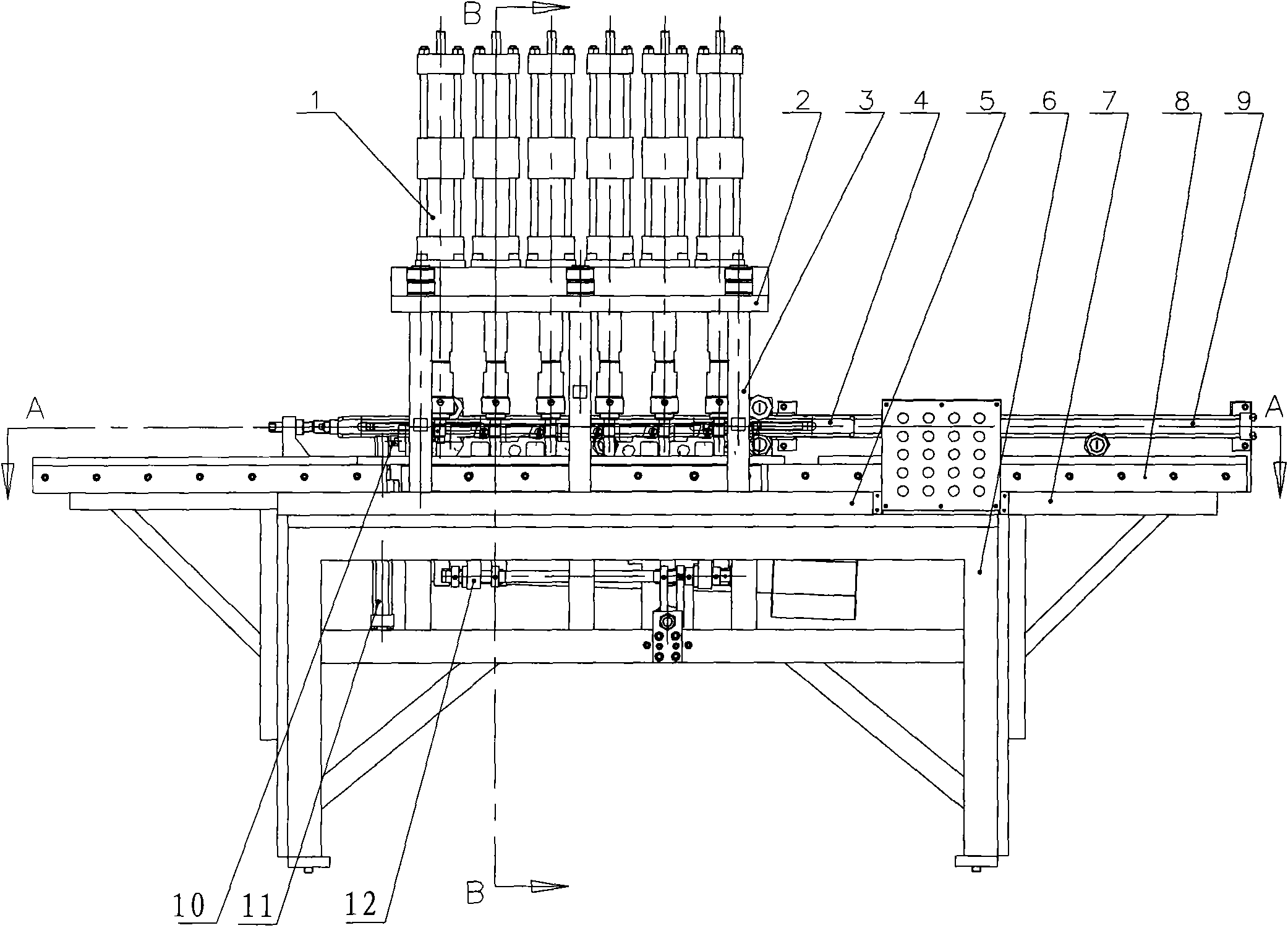

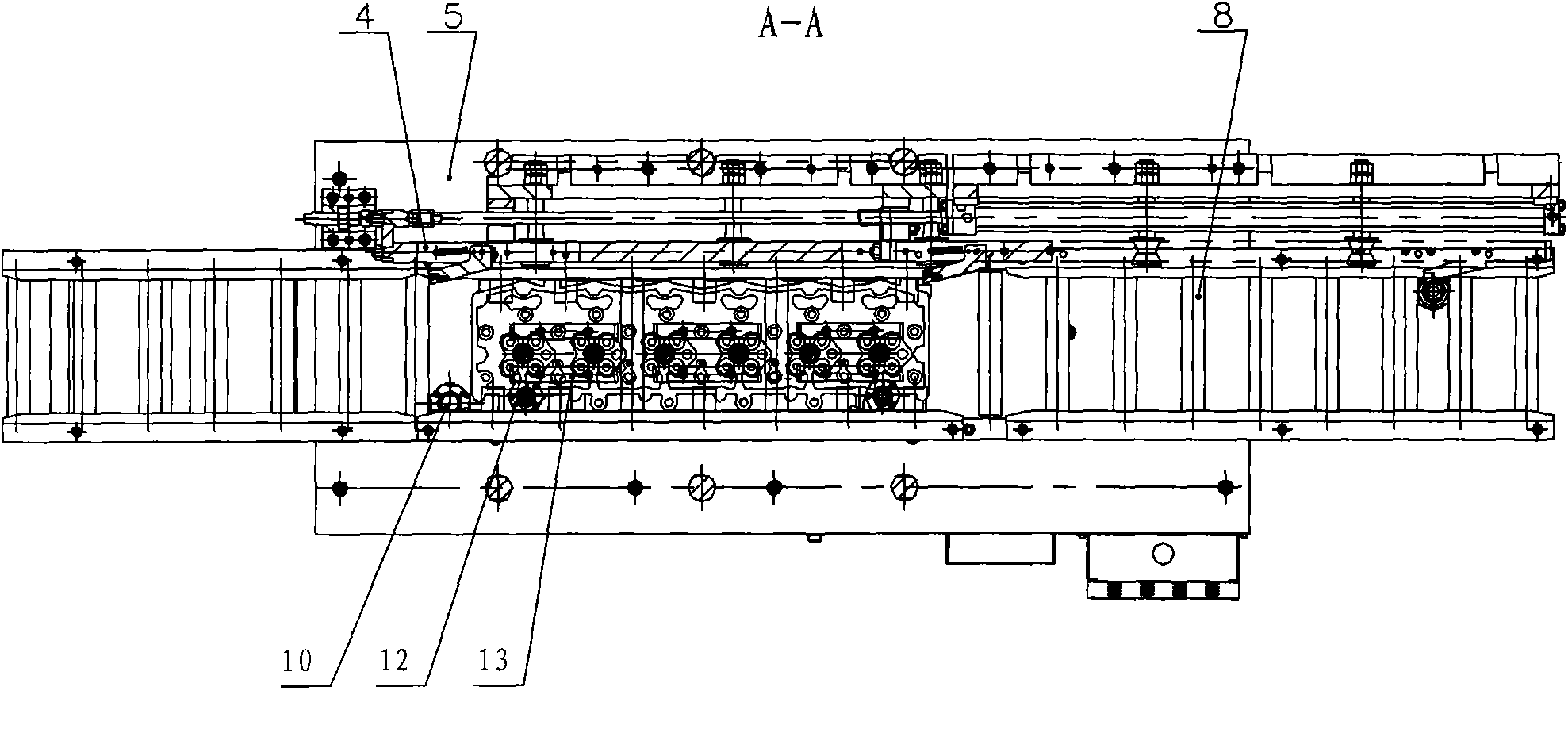

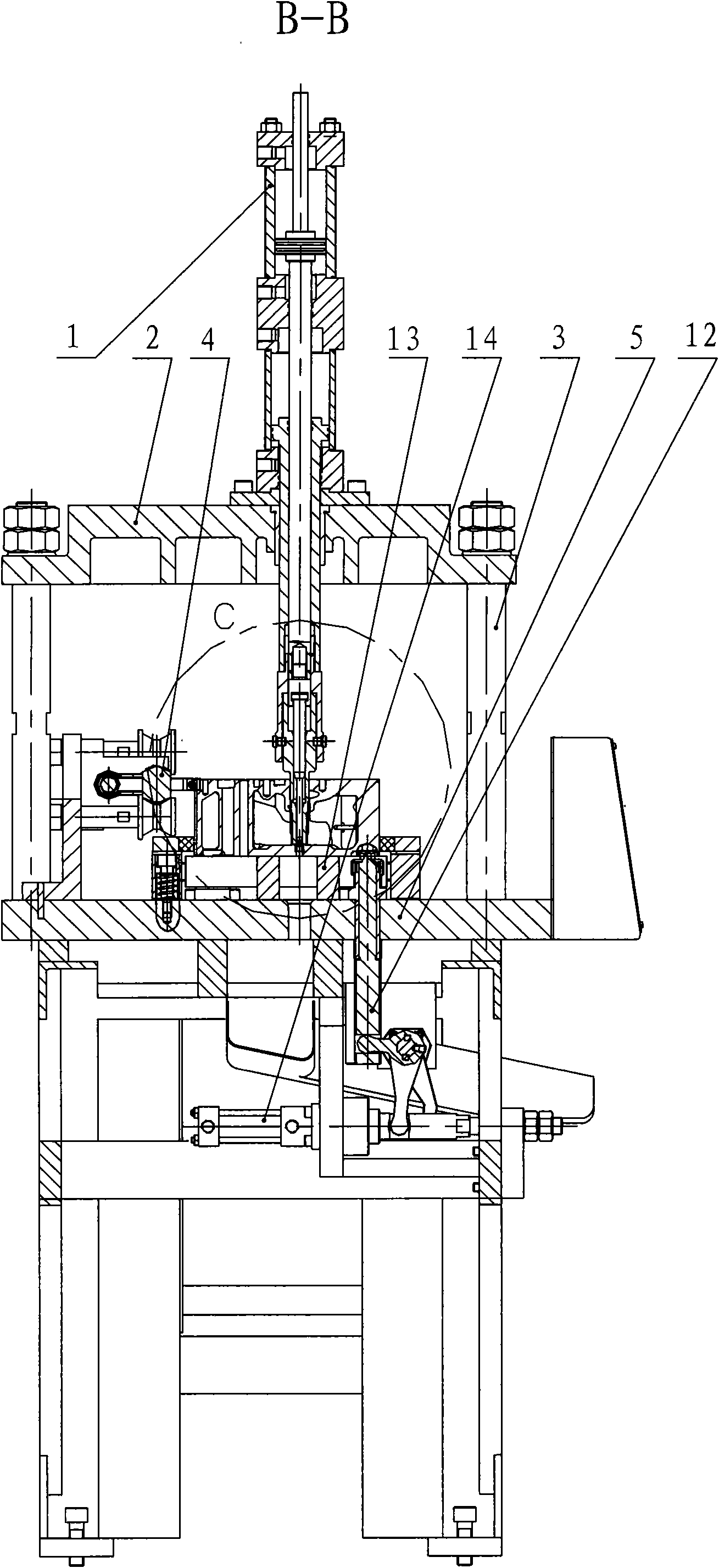

[0018] Such as Figure 1-6 As shown, a copper sleeve pressing machine includes a top plate 2 and a bottom plate 5, and the bottom plate 5 is directly installed on the top of the leg 6; the bracket 7 is fixed on the two ends of the leg 6 and is flush with the plane on the bottom plate 5; A raceway 8 is arranged above; the top plate 2 is integrated with the bottom plate 5 through six columns 3; the inner side of the bottom plate 5 is provided with a workpiece conveying device 4, and the workpiece conveying device 4 is driven by the first hydraulic cylinder 9 to realize the workpiece (cylinder) Cover) delivery; the outer left end of the base plate 5 is provided with a workpiece pre-positioning device 10, and the workpiece pre-positioning device 10 can realize the pre-positioning of the workpiece (cylinder head) through the drive of the second hydraulic cylinder 11; The workpiece process hole positioning mechanism 12 and the workpiece bottom surface positioning block 13, the workp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com