Battery stack press-fitting equipment

A stack and battery technology, which is applied in the field of battery stack press-fitting equipment, can solve the problems of crushing of bipolar plates and flow frames, affecting stack performance, and uneven force on the stack, and ensuring the quality of press-fitting. , Uniform force, avoid the effect of being crushed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

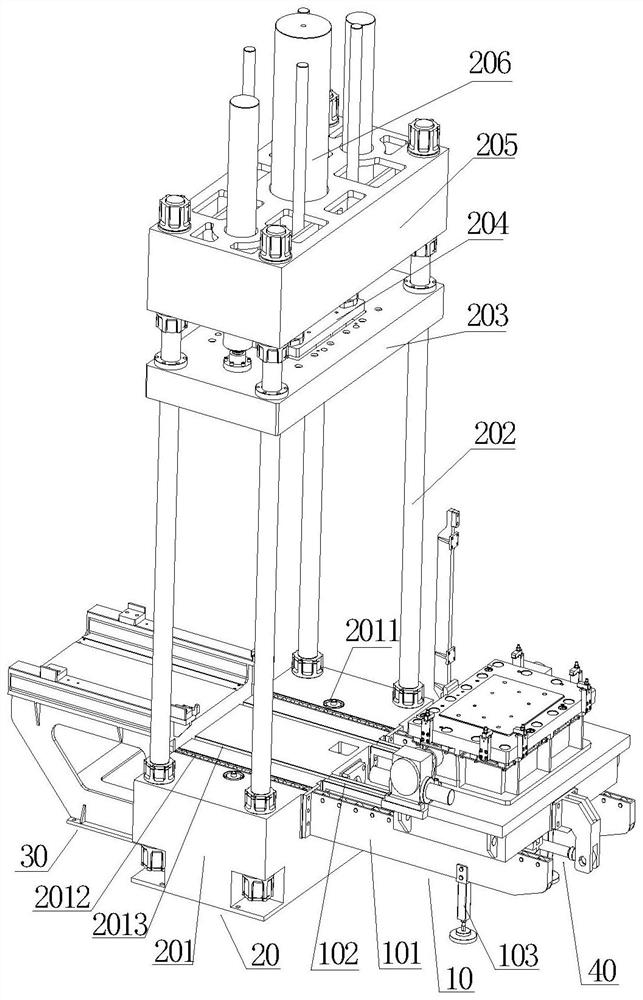

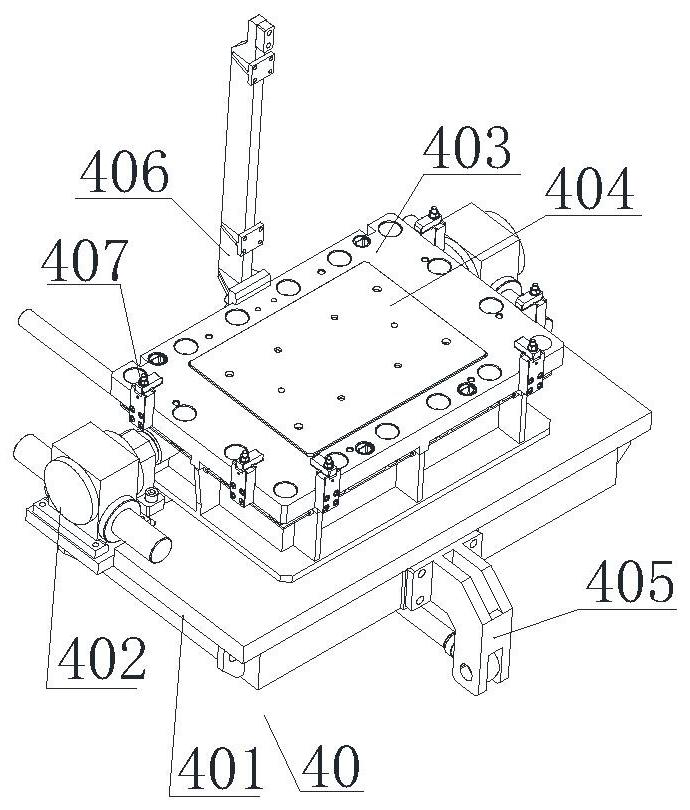

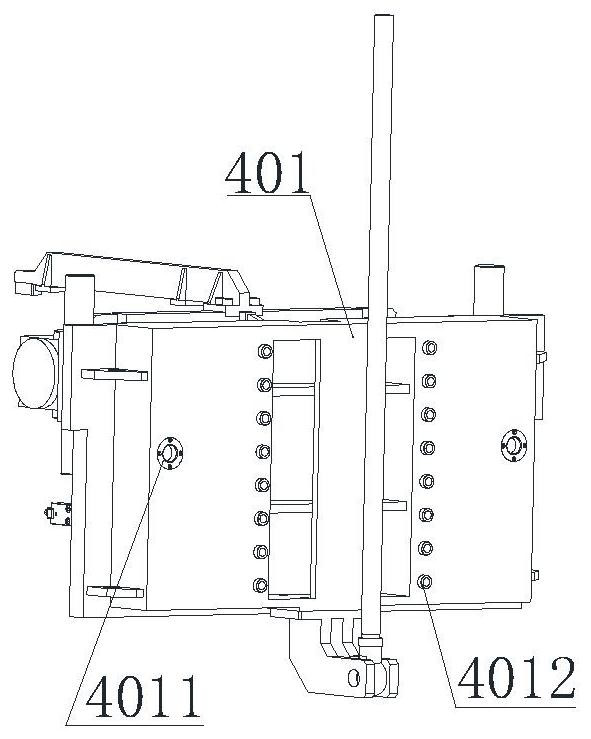

[0016] Please refer to Figure 1 to Figure 6 As shown, the battery cell stack pressing equipment includes a stacking support table 10, a moving mechanism 40, and a press 20. The press 20 includes a base 201, a guide column 202, a pressure head 204, and a driving mechanism 206. The guide column 202 is fixed on the base 201. Above, the pressure head 204 can slide along the guide column 202 under the driving action of the driving mechanism 206, the moving mechanism 40 can move from the stacking support platform 10 to the base 201, and the battery cell stack can be positioned on the stacking support platform 10 when the moving mechanism 40 When stacked on the moving mechanism 40 , the pressure head 204 is used to compress the battery cell stack arranged on the moving mechanism 40 .

[0017] The battery cell stack pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com