Combined press-mounting table for peeling roller of corn harvesting machine

A technology of corn harvester and peeling roller, which is applied in the direction of harvester, agricultural machinery and implements, threshing equipment, etc., and can solve the problems of easily damaged bearings, difficulty in keeping the shaft level, and large height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

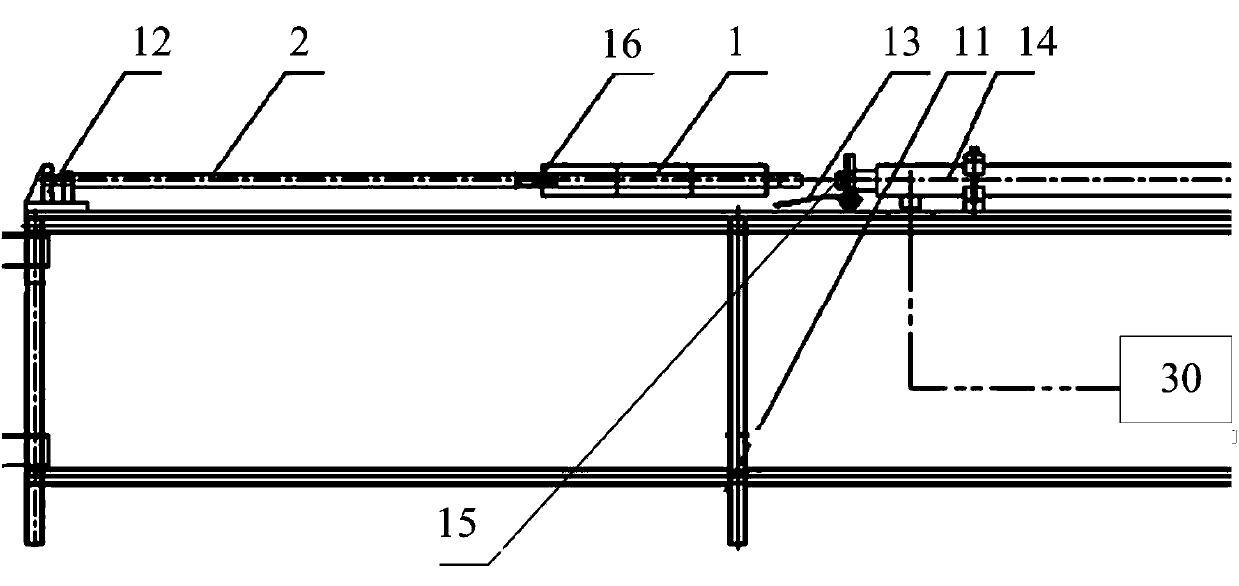

[0032] This embodiment discloses a corn harvester peeling roller combined pressing platform, such as figure 2 shown, including:

[0033] Peeling roller rubber sleeve pressing table 10, duplex bearing housing pressing table 20 and hydraulic station 30.

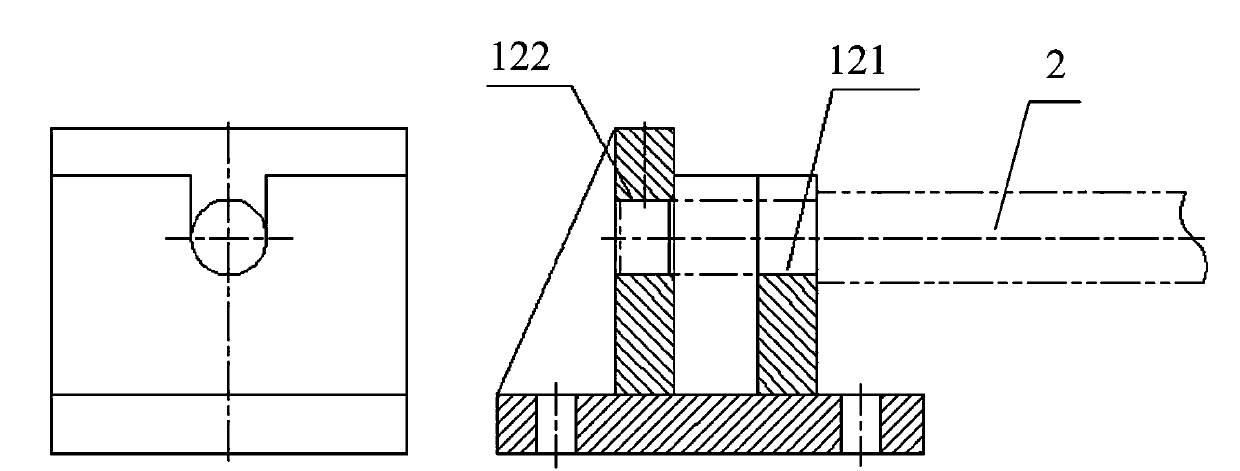

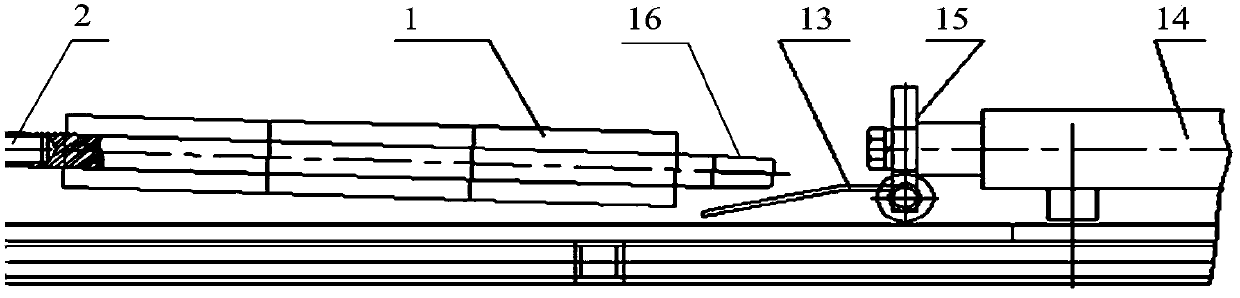

[0034] Among them, such as image 3 As shown, the peeling roller rubber sleeve pressing platform 10 includes: a first positioning seat 12 horizontally arranged on the first frame 11 in sequence, an alignment device 13 and a pressure head 15 fixed at one end of a large-stroke oil cylinder 14. The large-stroke oil cylinder 14 is connected with the hydraulic station 30 .

[0035] One end of the peeling roller shaft 2 is fixed on the first positioning seat 12, the other end of the peeling roller shaft 2 is supported on the connecting rod 16, and the peeling roller rubber sleeve 1 is sleeved on the connecting rod 16 in turn, the described The diameter of the butt end of the connecting rod 16 and the peeling roller shaft 2 is the...

Embodiment 2

[0049] This embodiment discloses another corn harvester peeling roller combination press-fitting platform. At least one pressure head is fixed on the large-stroke oil cylinder of the corn harvester peeling roller combination press-fitting platform. The difference from the above-mentioned embodiment is that, if Figure 12 As shown, in the peeling roller rubber sleeve press-fitting platform of the corn harvester peeling roller combination press-fitting platform disclosed in this embodiment, two pressure heads 15 are fixed on the large-stroke oil cylinder 14 . Then the described peeling roller rubber sleeve press-fitting station can simultaneously press-fit two groups of peeling roller rubber sleeves, greatly improving production efficiency.

Embodiment 3

[0051] This embodiment discloses a corn harvester peeling roller combination pressing method using the corn harvester peeling roller combination pressing platform described in the above embodiment, the method includes:

[0052] Use the peeling roller rubber sleeve press-fitting platform, from the connecting rod back to the peeling roller shaft, with the spherical end, manually put the peeling roller rubber sleeves into the connecting rod in sequence, the number of the peeling roller rubber sleeves is determined according to actual needs, Generally 3 to 5.

[0053] Fix one end of the peeling roller shaft in the positioning hole, support the shaft shoulder on the U-shaped groove, and extend the other end of the peeling roller shaft into the docking hole of the connecting rod covered with the rubber sleeve of the peeling roller. At this time, the connecting rod And the peeling roller shaft is just fixed on the described first frame. At this time, because the end of the connectin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com