Multi-point clamping device for product

A clamping device and product technology, applied in positioning device, clamping, supporting and other directions, can solve the problems of difficult positioning, poor quality and low efficiency of column-shaped products, and improve the limit efficiency and limit quality. The effect of limiting position and ensuring the quality of pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

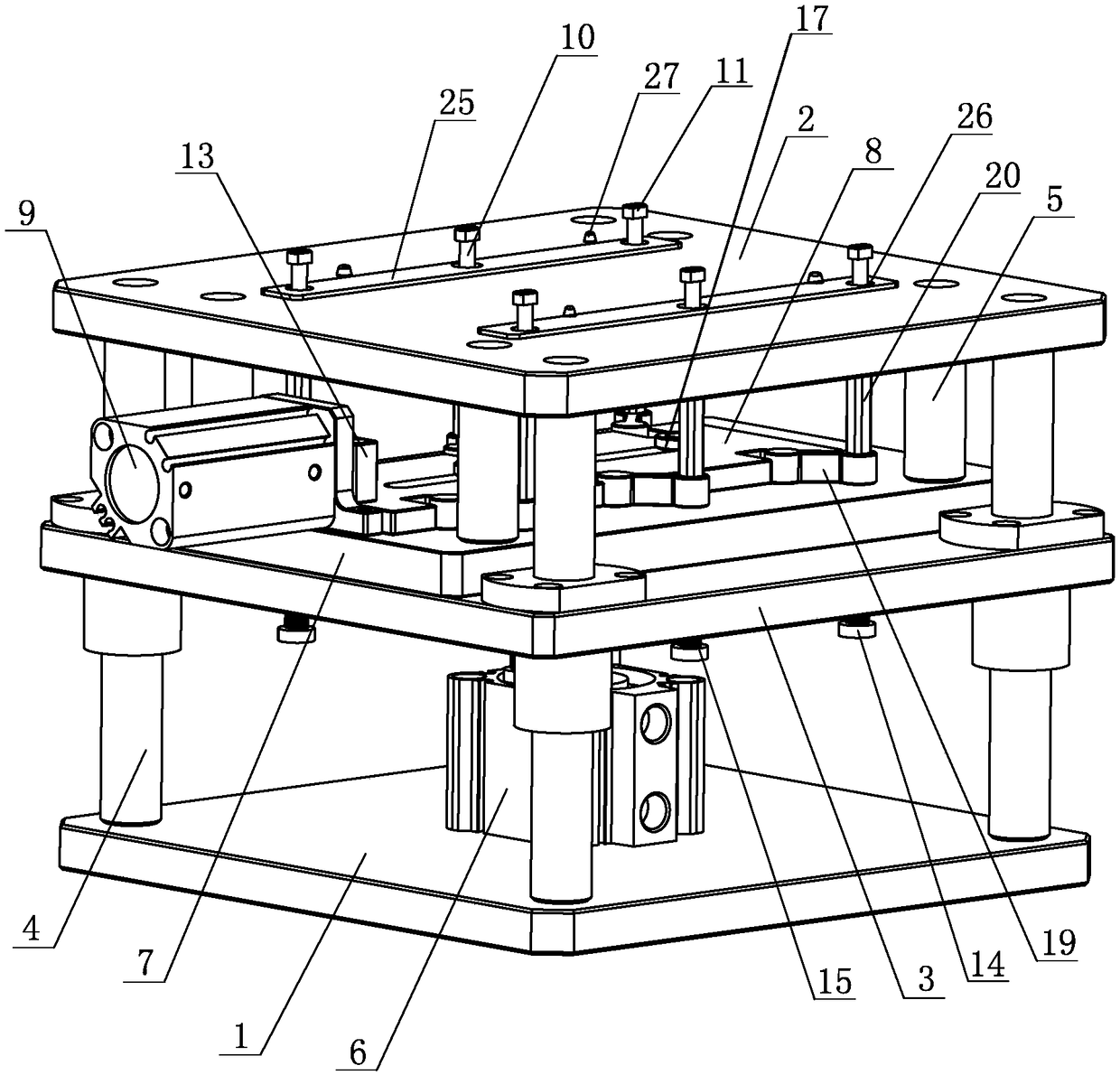

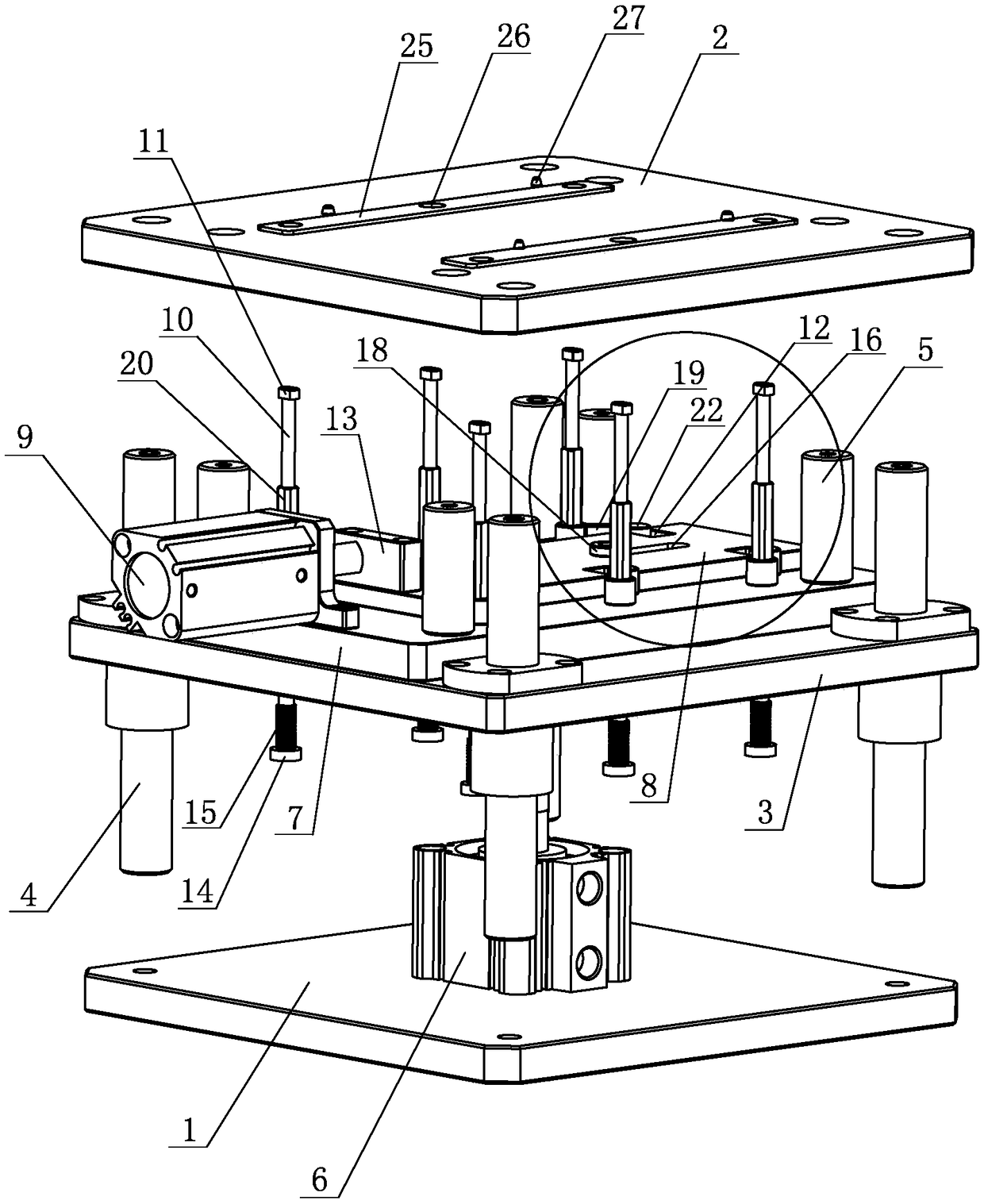

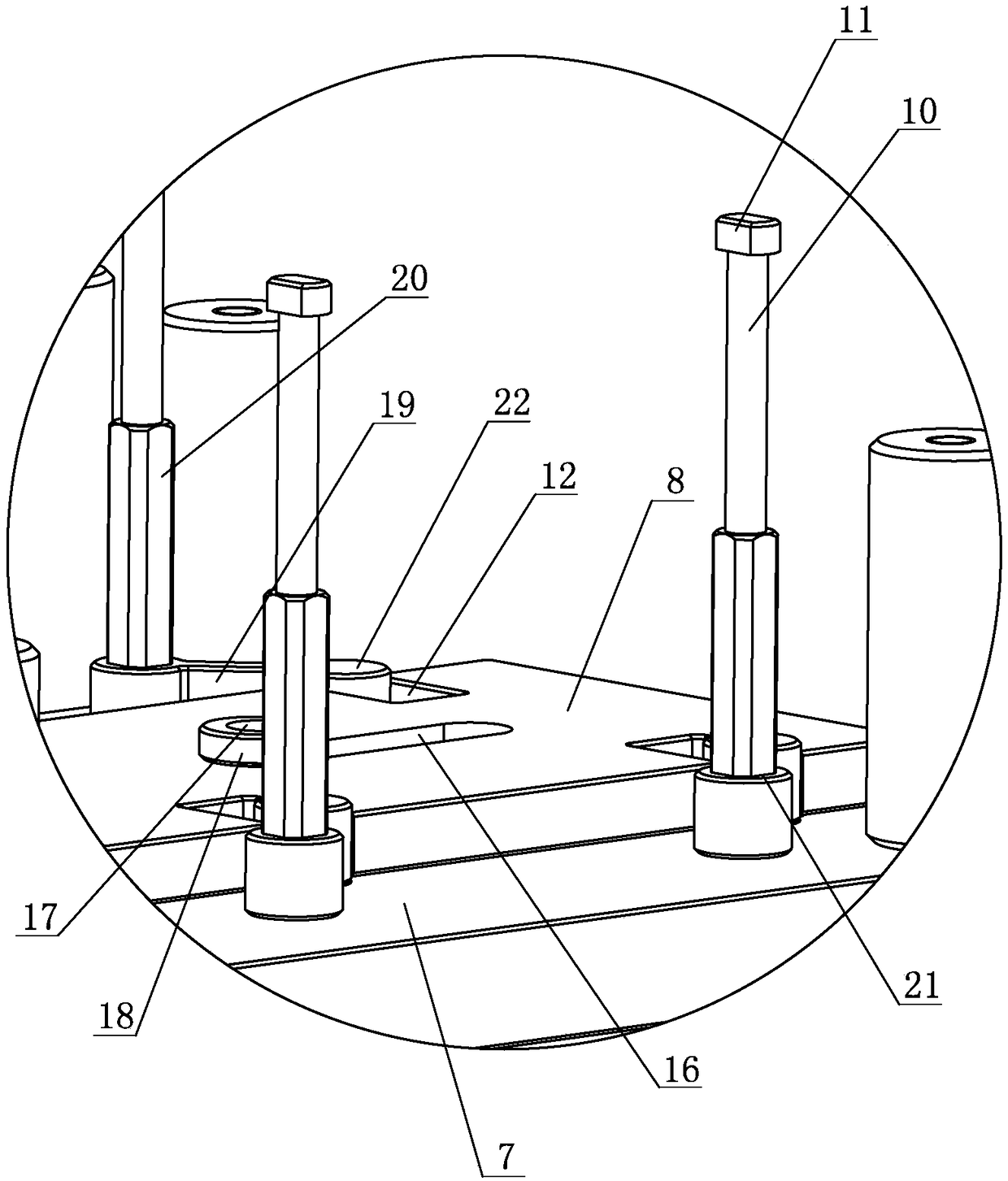

[0023] Embodiment one: see Figure 1~4 As shown, a product multi-point clamping device includes a bottom plate 1, a movable plate 2, a product carrying plate 3 and a clamping mechanism. The top surface is connected, the movable plate 2 is arranged between the bottom plate 1 and the product carrying plate 3, the movable plate 2 is slidably arranged on the four guide posts 4, and the clamping mechanism passes through the four The fixed column 5 is connected to the bottom surface of the product carrying plate 3, and the clamping mechanism is arranged above the movable plate 2; the bottom plate 1 is provided with a vertical telescopic cylinder 6, and the vertical telescopic cylinder 6 The output shaft is connected to the center of the bottom surface of the movable plate 2; the clamping mechanism includes a fixed plate 7, a slide plate 8, a horizontal telescopic cylinder 9 and 6 product limit rods 10, and the top surface of the fixed plate 7 is passed through The fixed column 5 is...

Embodiment 2

[0037] Embodiment 2: A multi-point clamping device for products. In this embodiment, its structure is basically similar to that of Embodiment 1. The difference is that no hollow connection collar and annular stopper are provided at the bottom of the polygonal sleeve hole. , but a magnetic layer is provided at the bottom of the connecting rod, and the magnetic layer is adsorbed on the top surface of the fixing plate. When the product limit rod moves up and down like this, the connecting plate will always be adsorbed on the top surface of the fixed plate through the magnetic layer, preventing the connecting plate from breaking away from the gap and ensuring the quality of use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com