Method for detecting, controlling and automatically compensating pressure in polishing process

An automatic compensation and pressure technology, which is applied in the direction of program control, electrical program control, workpiece feed movement control, etc., to achieve the effect of maintaining stable pressure, satisfying high precision and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

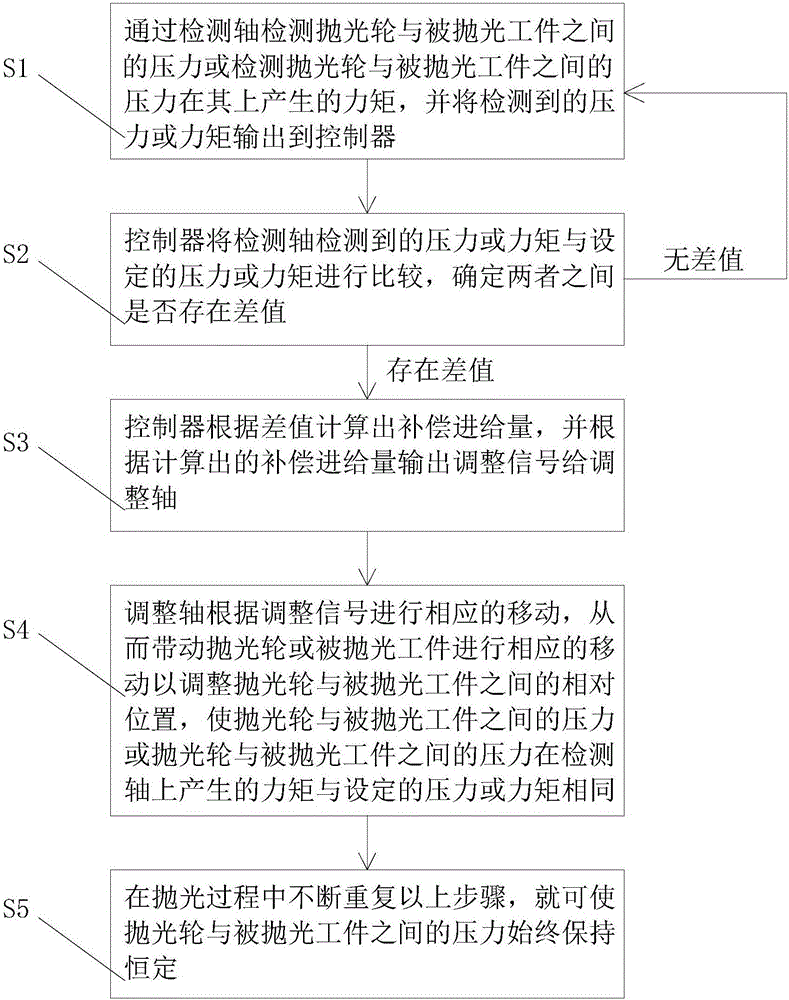

Method used

Image

Examples

no. 1 example

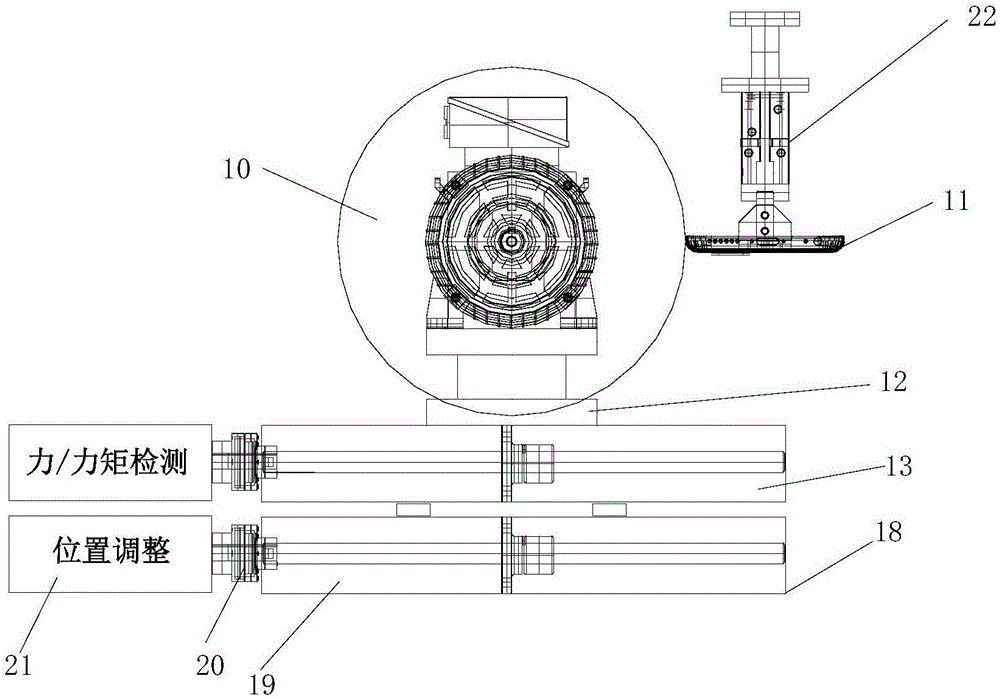

[0050] refer to figure 2 , in this embodiment, the substrate 12 of the polishing wheel 10 is fixed to the detection shaft 13, so that the center of the detection shaft 13 is located on the same vertical line as the center of the substrate 12, and is located on the same vertical line as the center of the polishing wheel 10. In-plane, that is, fixing the polishing wheel 10 to the test shaft. The polishing wheel 10 may be a grinding wheel. Fix the polished workpiece 11 to the polishing station 22 so that the center of the polished workpiece 11 and the center of the polishing wheel 10 are on the same horizontal line. The adjustment shaft 18 is fixed to the detection shaft 13 . The adjustment shaft 18 includes a main body 19 , a coupling 20 disposed on the main body 19 and a driver 21 fixed to the coupling 20 . The driver 21 receives an adjustment signal output by the controller and drives the main body 19 to move accordingly.

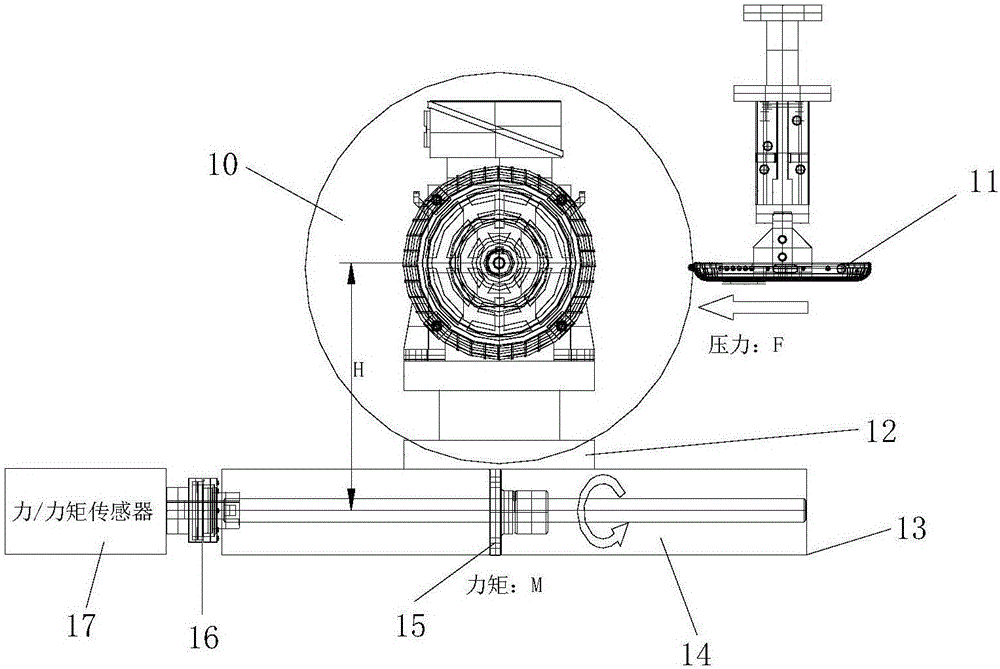

[0051] refer to image 3 , The detection shaft 1...

no. 2 example

[0058] In this example, refer to Figure 6 , different from the first embodiment, the polishing station 22 is fixed to the adjustment shaft 18 , that is, the workpiece 11 to be polished is fixed to the adjustment shaft 18 . The difference values determined by the controller are respectively described with examples below as positive difference values and negative difference values.

[0059] Still take the detection shaft 13 to detect the torque generated by the pressure between the polishing wheel 10 and the workpiece 11 to be polished as an example, assuming that the set torque M0 is 5%, the polishing wheel 10 and the workpiece 11 to be polished are not in contact with each other. The pressure F between them is 0, according to the pressure F=0, the pressure F between the polishing wheel 10 detected by the detection shaft 13 and the workpiece 11 to be polished produces a torque M1 on it that is 0, and the controller detects the detection shaft 13 The received torque M1 is ...

no. 3 example

[0062] refer to Figure 7 , unlike the first embodiment, the base plate 12 of the polishing wheel 10 is fixed to the adjustment shaft 18 , ie the polishing wheel 10 is fixed to the adjustment shaft 18 . The polishing station 22 is fixed to the detection axis 13 , that is, the polished workpiece 11 is fixed to the detection axis 13 . The center of the polished workpiece 11 and the center of the detection axis 13 are located in the same vertical plane. The detection shaft 13 detects the pressure or torque between the polishing wheel 10 and the workpiece 11 to be polished in the same principle as the first embodiment, which will not be repeated here. The difference values determined by the controller are respectively described with examples below as positive difference values and negative difference values.

[0063]Still take the detection shaft 13 to detect the torque generated by the pressure between the polishing wheel 10 and the workpiece 11 to be polished as an example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com