Optical fiber grating self-compensating strain transducer produced by on-line molding process

A technology of strain sensor and optical fiber grating, which is applied in the direction of using optical devices, instruments, measuring devices, etc., can solve the problems of easy creep of grating adhesive process, unreliable combination of grating, easy aging, etc. Reliable, reliable performance, low cost results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

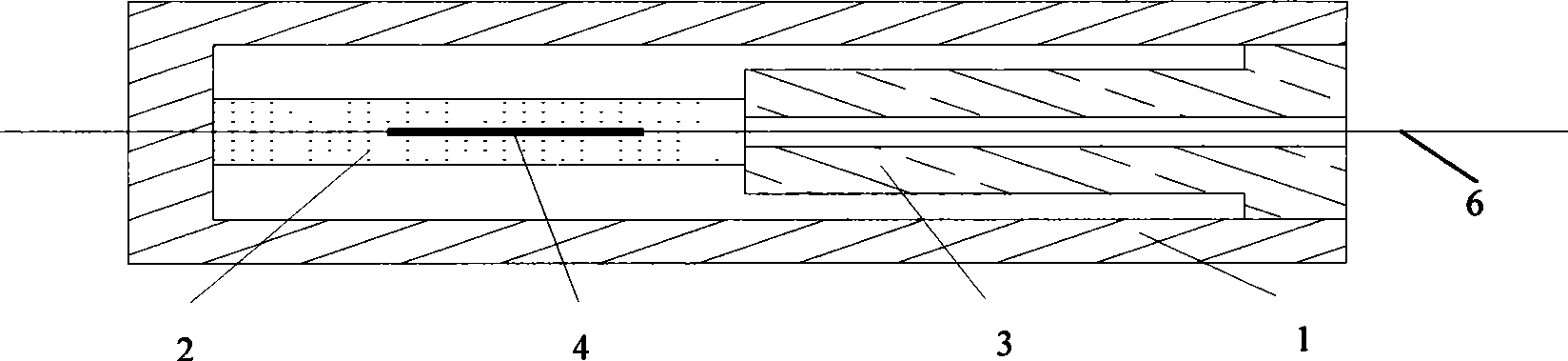

[0025] see Figure 1 ~ Figure 3 : The fiber grating strain sensor with temperature self-compensation function is provided with a compensation device, and the compensation device is composed of a serial connection between part B 3 and solid body 2, and part B 3 is a metal tube; the optical fiber is a multimode optical fiber, and the fiber grating 4 is a whole Embedded and fixed in the solid body 2, the optical fiber passes through the inner hole of the piece B3. Both the metal outer tube 1 and the part B 3 are metal materials with a positive temperature coefficient. The solid body 2 is a material with a negative temperature coefficient, which is an aramid fiber reinforced resin matrix composite material. The fiber grating 4 is a fiber Bragg grating. The two ends of the compensation pipe are fixed on the fixing frame body. The fixed frame body is a metal outer tube 1 . The two ends of the solid body 2 are fixed on the piece B 3 and the metal outer tube 1 with a two-component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com