Capacity grading compensation method

A compensation method and a capacity-dividing technology, applied in the field of capacity-dividing compensation, can solve the problems of false high capacity, cell capacity deviation, low capacity, etc., and achieve the effect of high cost efficiency, low cost, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This embodiment provides a capacity division compensation method, including the following steps:

[0020] Step 1: Under different temperature environments, test the discharge capacity of the same system cell, and use a mathematical model to perform nonlinear fitting between the test temperature and discharge capacity of the cell, and the formula is as follows:

[0021] C 容量 =C 实测容量 +K 1 *(T 实测 -25) 3 +K 2 *(T 实测 -25) 2 +K 3 *T 实测 +B

[0022] Among them, C 容量 is the discharge compensation capacity in mAh; C 实测容量 is the actual discharge capacity in mAh; K 1 、K 2 and K 3 Both are compensation coefficients; T 实测 is the compensation temperature value; B is the offset coefficient;

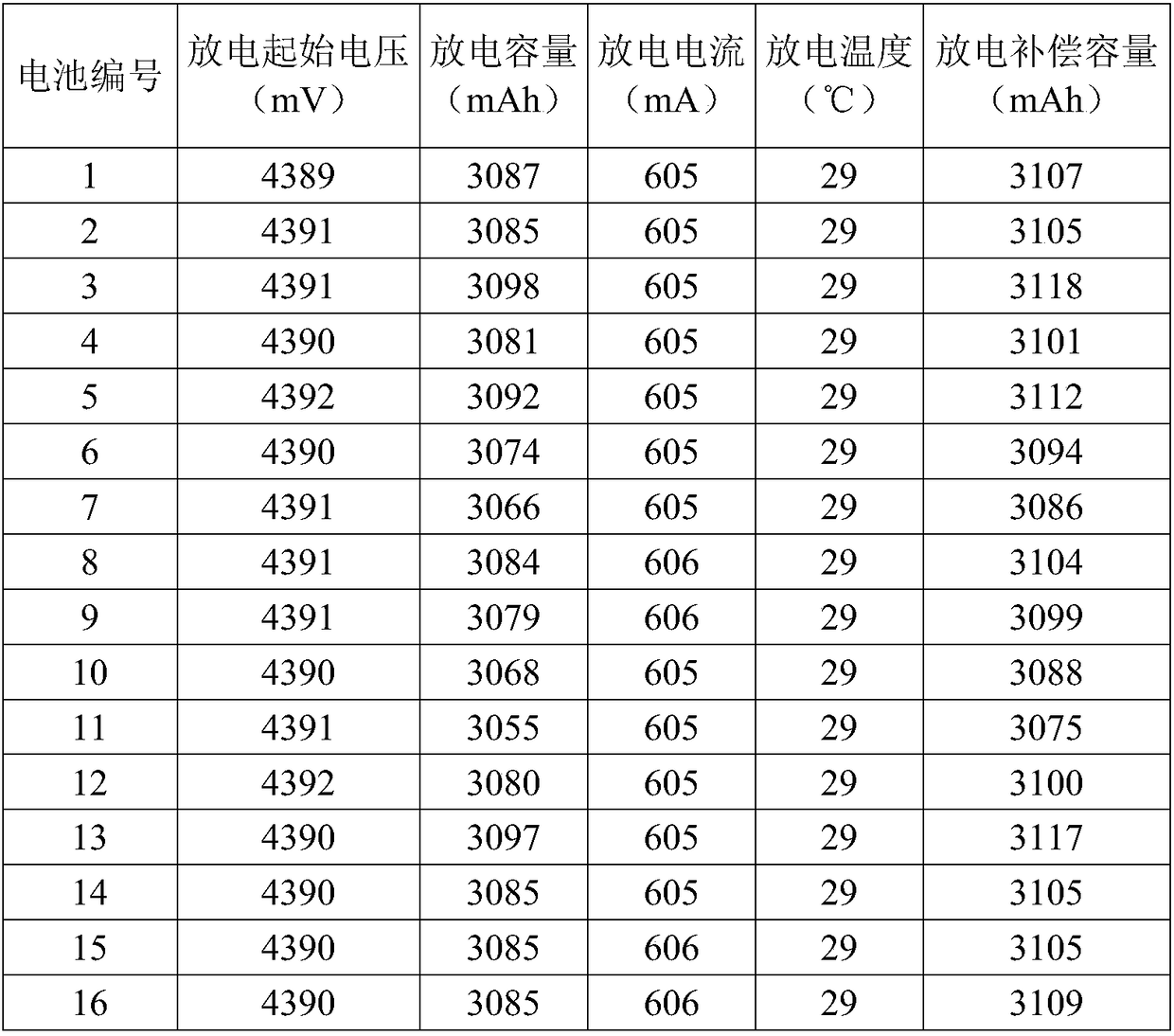

[0023] Step 2: During the capacity separation test, record the initial discharge voltage, discharge current, discharge temperature and actual discharge capacity, select the average value of the discharge temperature as the compensation temperature value, and set the compensation co...

Embodiment 2

[0026] This embodiment provides a capacity division compensation method, including the following steps:

[0027] Step 1: Under different temperature environments, test the discharge capacity of the same system cell, and use a mathematical model to perform nonlinear fitting between the test temperature and discharge capacity of the cell, and the formula is as follows:

[0028] C 容量 =C 实测容量 +K 1 *(T 实测 -25) 3 +K 2 *(T 实测 -25) 2 +K 3 *T 实测 +B

[0029] Among them, C 容量 is the discharge compensation capacity in mAh; C 实测容量 is the actual discharge capacity in mAh; K 1 、K 2 and K 3 Both are compensation coefficients; T 实测 is the compensation temperature value; B is the offset coefficient;

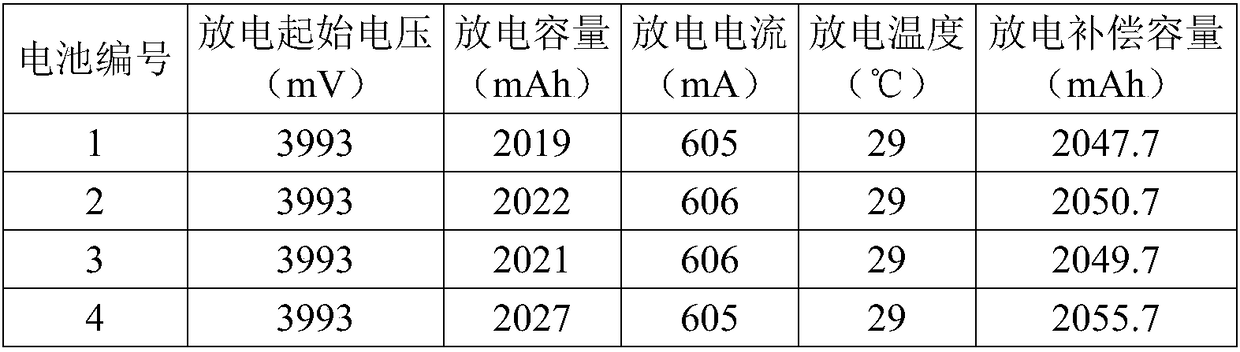

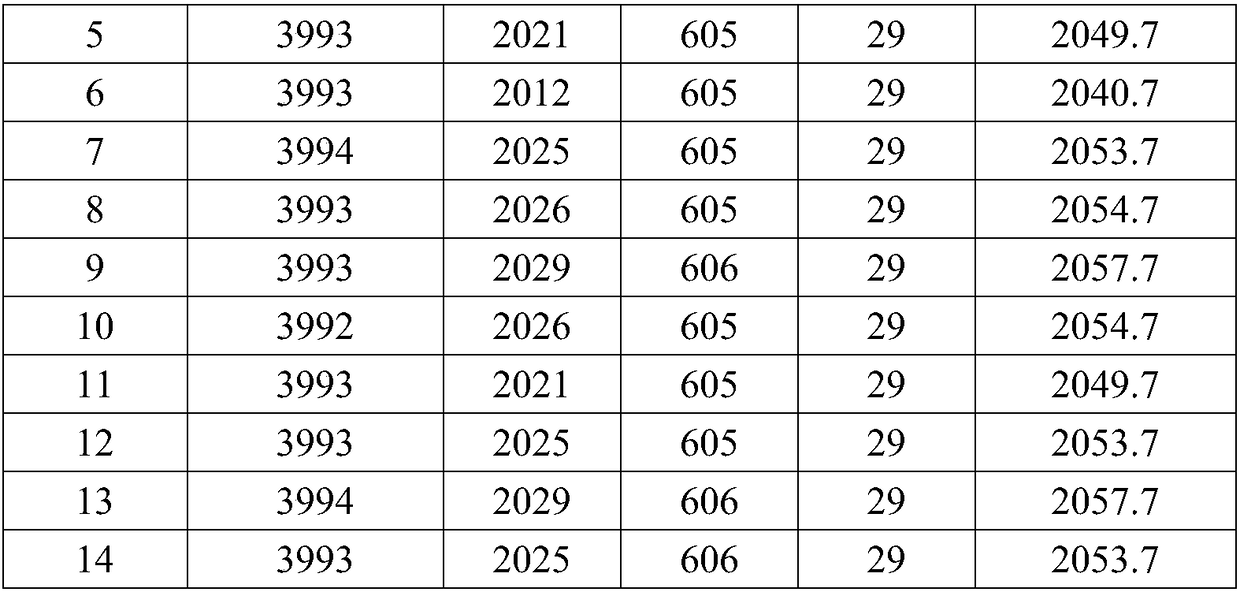

[0030] Step 2: During the capacity separation test, record the initial discharge voltage, discharge current, discharge temperature and actual discharge capacity, select the average value of the discharge temperature as the compensation temperature value, and set the compensation co...

Embodiment 3

[0033] This embodiment provides a capacity division compensation method, including the following steps:

[0034] Step 1: Under different temperature environments, test the discharge capacity of the same system cell, and use a mathematical model to perform nonlinear fitting between the test temperature and discharge capacity of the cell, and the formula is as follows:

[0035] C 容量 =C 实测容量 +K 1 *(T 实测 -25) 3 +K 2 *(T 实测 -25) 2 +K 3 *T 实测 +B

[0036] Among them, C 容量 is the discharge compensation capacity in mAh; C 实测容量 is the actual discharge capacity in mAh; K 1 、K 2 and K 3 Both are compensation coefficients; T 实测 is the compensation temperature value; B is the offset coefficient;

[0037] Step 2: During the capacity separation test, record the initial discharge voltage, discharge current, discharge temperature and actual discharge capacity, select the average value of the discharge temperature as the compensation temperature value, and set the compensation co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com