Michelson's interferometer integrated into single optical fiber

A single optical fiber and interferometer technology is applied in the field of optoelectronics to achieve the effects of simplified and compact system, reduced volume and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

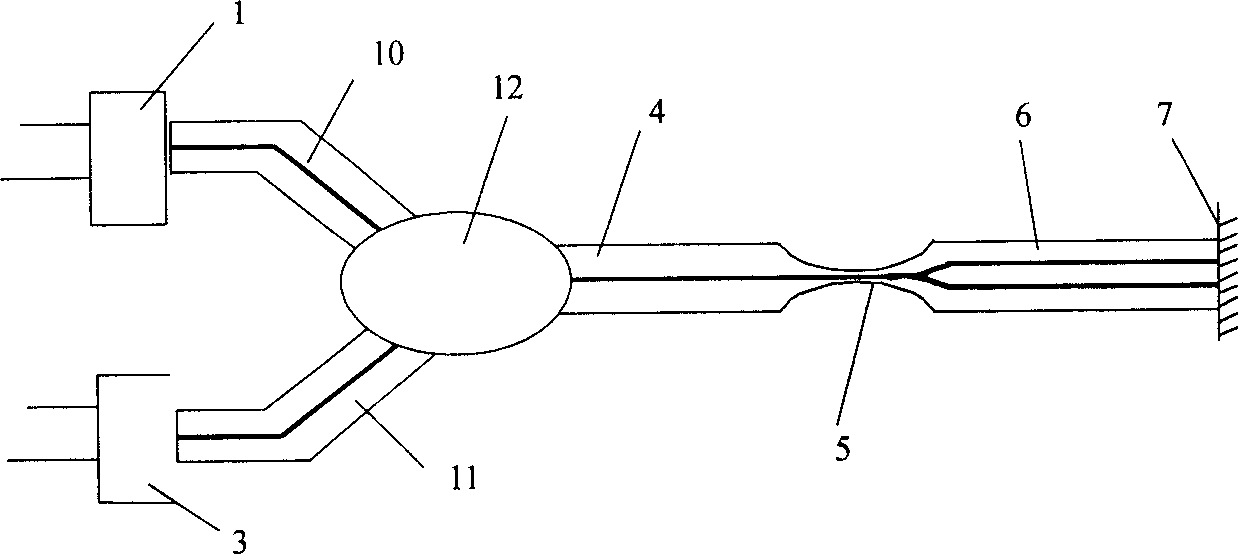

[0011] Three specific embodiments of the present invention are given below in conjunction with the drawings.

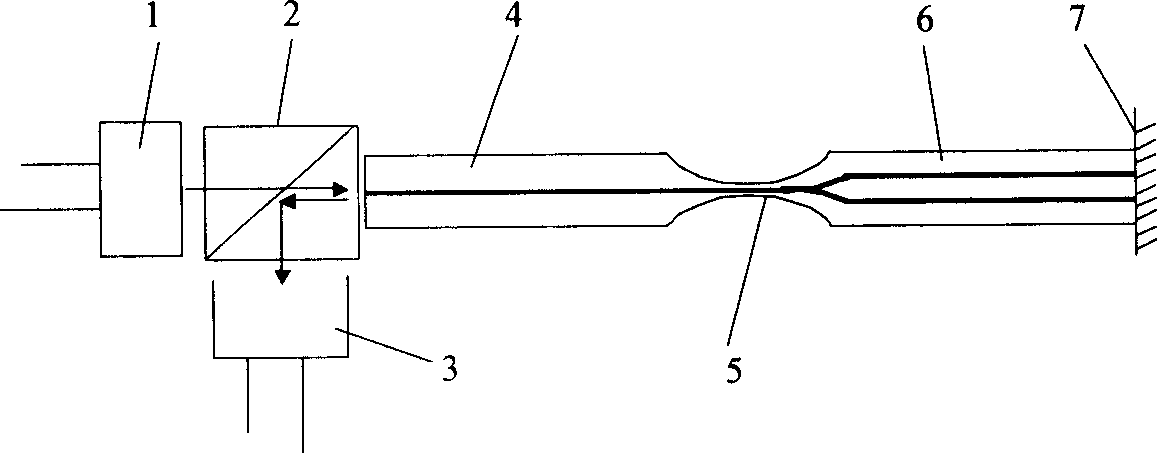

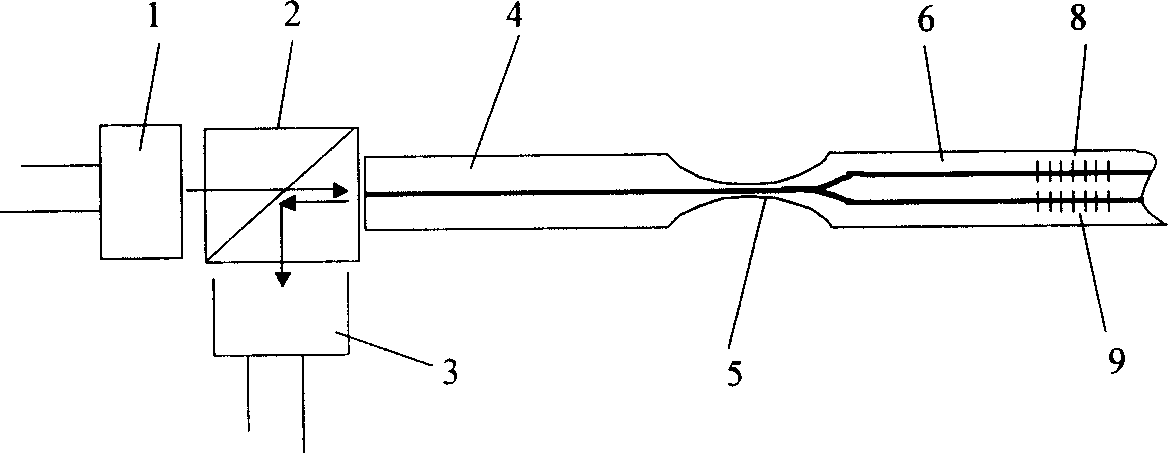

[0012] figure 1 The first specific embodiment of the present invention is shown. The Michelson interferometer integrated into a single fiber includes a light source 1, a micro-splitter 2, a light detector 3, a single-mode single-core fiber 4, a tapered coupling region 5, a single-mode twin-core fiber 6 and a mirror 7. Usually, the light source 1, the micro-splitter 2 and the photodetector 3 are combined into a light transmitting and receiving duplex device with pigtail.

[0013] The light source 1, the photodetector 3, the micro beam splitter 2 and the single-mode single-core fiber 4 are usually an independent duplex component. The single-mode single-core fiber 4 of the component is connected to a section of the single-mode dual-mode single-mode fiber whose end surface is plated with a mirror 7. The core optical fiber 6 is welded, and then the tapered coupling region 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com