Flanging device and flanging method with component protection

A technology of hemming and equipment, which is applied in the field of hemming equipment, can solve problems and the quality of hemming is not always satisfactory, and achieve the effect of accurate replication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

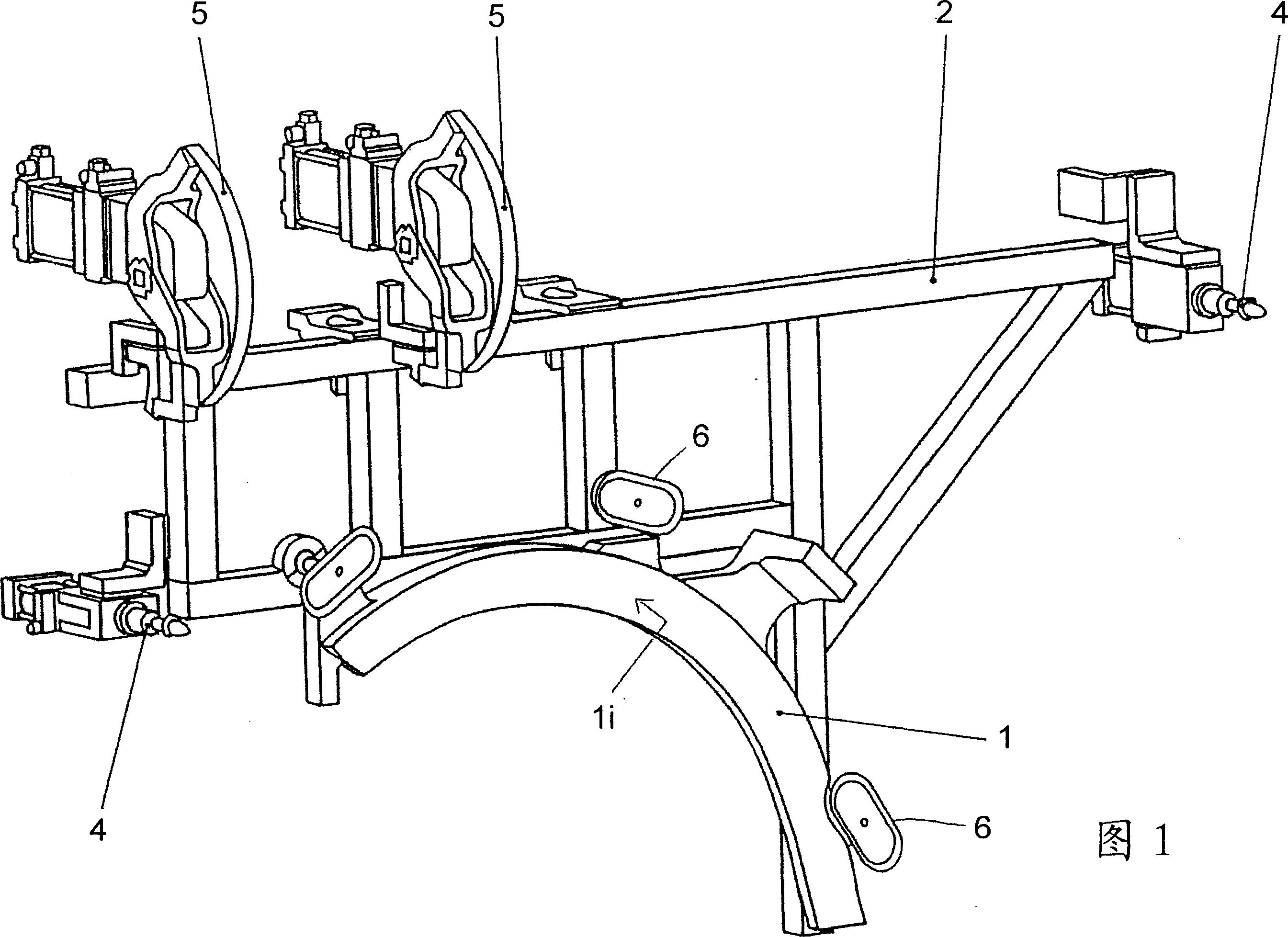

[0036] FIG. 1 shows a protective strip 1 within a frame 2 . As will be appreciated, the protective strip 1 follows the trajectory of the wheel section. Its inner side 1i, visible in the figure, exhibits a contour that is a negative replication of the desired body contour on the wheel arches. The outer profile is usually not smooth, but is often provided with different facets and vertical structures in order to obtain a certain aesthetic effect and / or a smooth transition to adjacent body parts. The profile must not be destroyed.

[0037] The frame 2 comprises a number of markers in the form of positioning pins 4 which engage with corresponding holes in the body so as to positively fix the protective strip 1 relative to the body. Mechanical clamps 5 hold the frame 2 so that the protective strip 1 is clamped to the body.

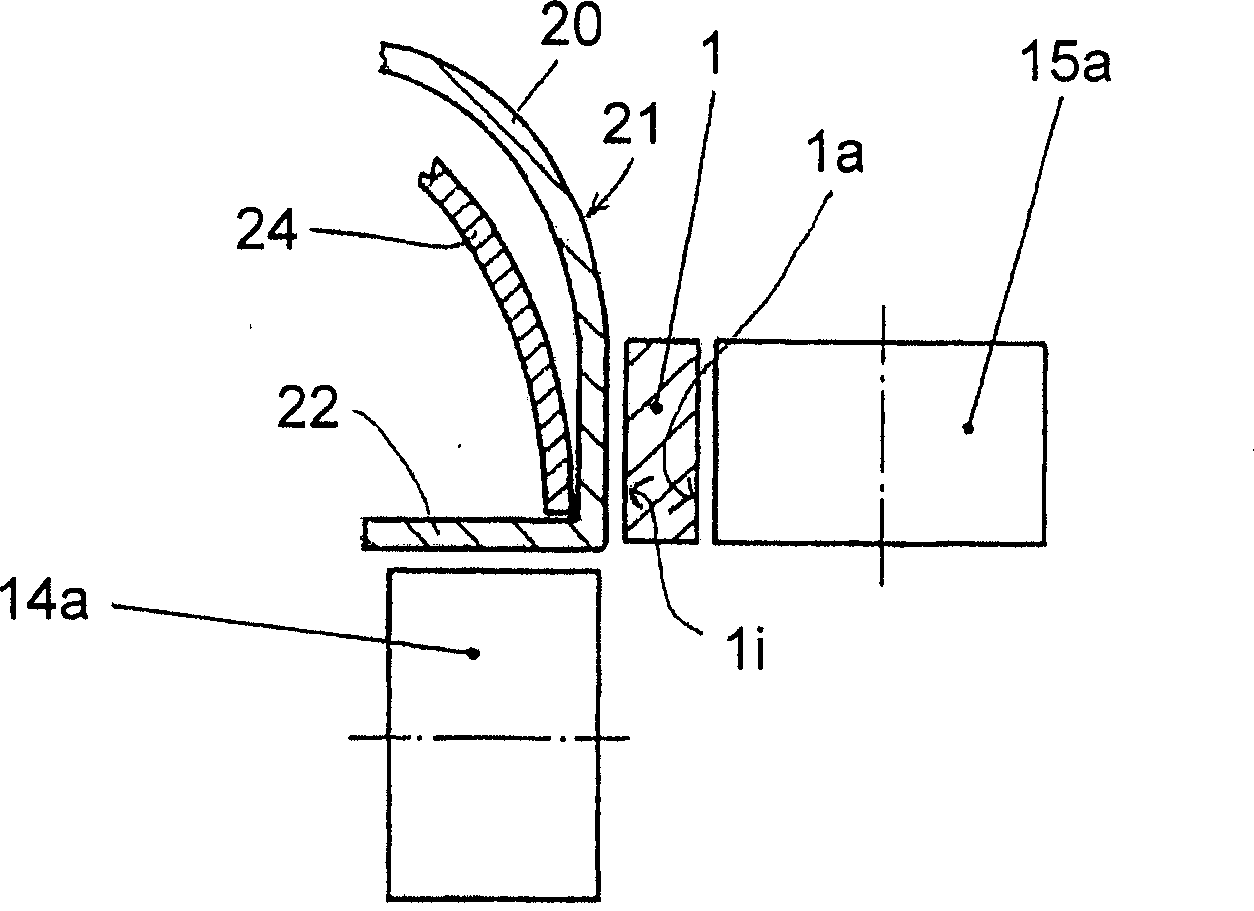

[0038] The outer side of the protective strip 1 is smooth and forms the rolling surface 1a for the counter-pressure roller of the hemming head (FIG. 3).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com